Digital Microscopes

Observation and Analysis for Evaluation of Solar Cells

In recent years, the reduction of fossil fuel consumption and the use of photovoltaics have become popular ways to prevent global warming and otherwise preserve the environment. The main advantage of solar cells is that an unlimited amount of energy can be obtained anywhere exposed to sunlight with no damage to the environment. For this reason and because the power generation efficiency does not depend on the scale of the equipment, the demand for photovoltaics is growing.

This section introduces basic knowledge of solar cells and introduces examples of the best methods for observation and analysis.

Operating Principle, Structure, and Power Conversion Efficiency of Solar Cells

The major solar cells currently available are silicon solar cells or compound semiconductor solar cells. Although silicon solar cells are most commonly used, the market share held by compound semiconductor solar cells is increasing because they have an advantage in terms of production costs. The basic operating principle and structure of solar cells, as well as typical materials and power conversion efficiencies of silicon and compound semiconductor solar cells, are explained below.

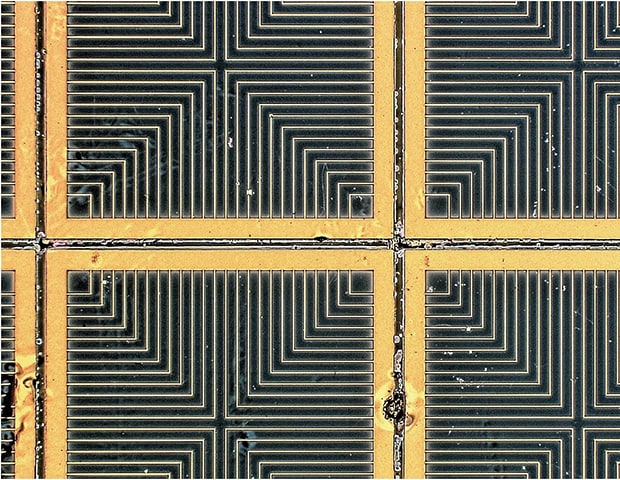

A: Anti-reflection film B: n-type silicon C: p-type silicon D: Electrodes E: Current

Operating principle of solar cells

Silicon solar cells, which are commonly used, have an internal junction of two types of semiconductors, the p-type and n-type, each having different electric properties.

When a solar panel is exposed to sunlight, electrons (negative) and holes (positive) are generated. Holes are attracted to the p-type semiconductor, while electrons are attracted to the n-type semiconductor. For example, when a load, such as a light bulb, is connected to the electrodes of the front and back sides, electrical current passes through the junction as shown in the following figure.

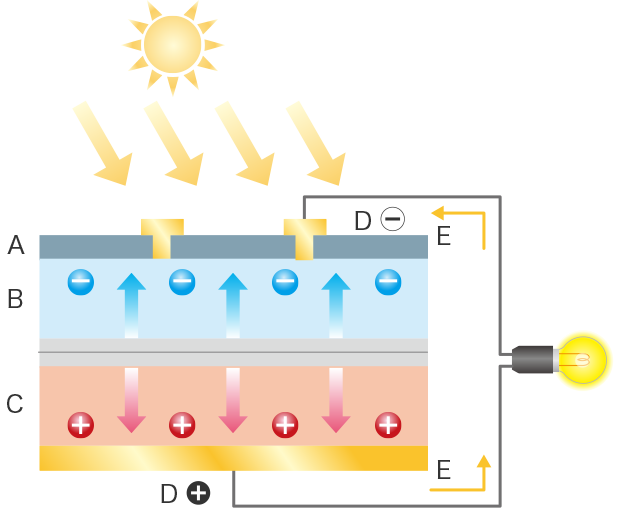

A: Cell B: Module C: Array

Structure of solar cells

The units and their names are explained and illustrated in the figure below.

Cell

A cell is the minimum unit.

Cell string or cell array

A single cell outputs a low voltage. A cell string contains multiple cells connected in series to generate the required voltage.

A cell array contains multiple cell strings connected in serial or parallel to further increase the output.

Module

A module, also called a solar panel, is a package containing multiple cell arrays for outdoor use. A module is covered with resin or reinforced glass to protect the internal cells and is attached with an outer frame to enhance its strength.

Array

Multiple modules are connected to form an array.

Power conversion efficiencies and materials of solar cells

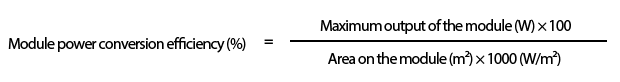

An important performance indicator of solar cells is power conversion efficiency. Power conversion efficiency is a parameter that shows the fraction of incident sunlight energy converted into electric energy. Module power conversion efficiency and cell power conversion efficiency are two representative indicators for photovoltaic power conversion efficiency. The two power conversion efficiencies are explained below.

Module power conversion efficiency

Module power conversion efficiency is commonly used to indicate the power generation ability of a solar module (solar panel). Module power conversion efficiency is a percentage of electric energy converted from approximately 1 kW of light energy per 1 m² (10.76 ft²) of solar module.

Cell power conversion efficiency

A cell is the minimum unit that makes up a solar module. Cell power conversion efficiency indicates the power conversion efficiency per solar cell. Cell power conversion efficiency can be derived with the following formula.

With continued research and development, module and cell power conversion efficiencies are improving year after year. However, modern technology cannot absorb 100% of the incident light energy and convert 100% of the absorbed light energy into electricity due to various factors such as light reflection on solar panels and the resistance of the cells.

Materials and characteristics of solar cells

Solar cells use various materials according to the functions required by the application and expected costs. Power conversion efficiency varies accordingly. Therefore, manufacturers are working on research and development of materials and manufacturing processes to achieve higher power conversion efficiency and lower costs.

Below, solar cells are categorized into the silicon and compound semiconductor type; the representative materials and their characteristics are explained for each type.

Silicon solar cell

- Monocrystal

Solar cells using monocrystalline silicon are expensive but have high conversion efficiency and reliability. - Polycrystal

Polycrystalline silicon cells are most commonly used because polycrystalline silicon is cheaper than monocrystalline silicon. - Amorphous silicon

Because amorphous silicon is non-crystalline silicon, solar cells using amorphous silicon are cheaper than those using polycrystalline silicon but have low power conversion efficiency. - Multi-junction cells

Various types of solar cells, including amorphous silicon and thin film polycrystalline silicon, are laminated to make a tandem structure. This type of solar cell has high power conversion efficiency.

Compound semiconductor solar cell

- Copper indium selenide (CIS)

CIS solar cells are made from copper, indium, and selenide. This type of solar cell can be manufactured at low cost but has relatively high power conversion efficiency. - Copper indium gallium selenide (CIGS)

CIGS solar cells use four elements, gallium added with the three elements used for CIS. This type of solar cell has power conversion efficiency slightly higher than CIS solar cells. - Cadmium telluride (CdTe)

CdTe solar cells are made from cadmium and tellurium. This type is mainly used in Europe. - Gallium arsenide (GaAs)

GaAs solar cells are made from gallium and arsenide. This type of solar cell has high power conversion efficiency but is expensive. It is used in satellites and in similar applications.

Get detailed information on our products by downloading our catalog.

View Catalog

Problems in Observation, Measurement, Analysis, and Evaluation of Solar Cells

In the photovoltaic industry, with the need to preserve the environment and the growing demand for renewable energy, manufacturers are competing to develop solar cells that provide higher power conversion efficiency at lower costs. Also, high levels of quality assurance and control are necessary to provide stable photovoltaic and power storage products and maintain reliability in the aftermarket.

Solar cells have surface irregularities to increase the surface area. Each section has a mix of various materials with varying colors and glossy surfaces. This makes it difficult to accurately observe, measure, and analyze microscopic parts—such as electrodes—of defective products and prototypes, making these operations time intensive.

A lot of time, effort and a high level of expertise are required for observation, measurement, and analysis using conventional microscopes. Even when experts use a scale for visual measurement, the measured values can vary from operator to operator.

Preparation takes a lot of time and effort when using a scanning electron microscope (SEM) for cross-section measurement. It is also difficult to identify materials and foreign particles in defective areas because SEMs do not support color observation.

We’re here to provide you with more details.

Reach out today!

Examples of how to Improve the Observation, Measurement, and Analysis of Solar Cells

The recent technological progress of digital microscopes eliminates the problems faced by conventional microscopes and dramatically improves the efficiency of observation, measurement, and analysis. KEYENCE's VHX Series digital microscope has an automatic assist function that allows users to easily capture high-resolution images, count particles, and accurate 2D/3D measurements of solar cells. By combining cutting-edge high-resolution lenses, a 4K CMOS image sensor, advanced lighting capabilities, and image processing technologies, the VHX Series dramatically improves the observation and analysis of solar cells.

See below for observation, measurement, and analysis examples of solar cells using the VHX Series.

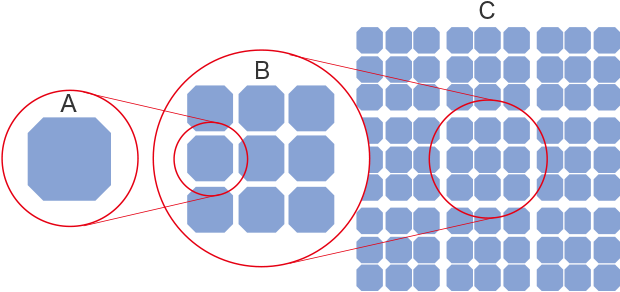

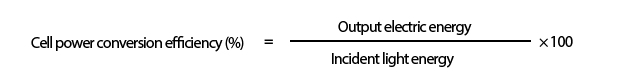

3D shape measurement of electrodes

To increase the power conversion efficiency of solar cells, it is necessary to minimize the width and also the height of the electrodes. When an expensive material, such as gold, is used for electrodes, minimizing the volume can reduce the cost.

It is difficult to accurately measure fine electrode shapes using conventional microscopes, making it impossible to measure 3D shapes instantaneously.

With the VHX Series 4K digital microscope, 3D shapes can be measured with micrometer level precision using a magnified high-resolution image. By overlaying a color map on the 3D image, the VHX Series easily visualizes height data and profile measurements at multiple locations, making it easy to compare microscopic shapes.

3D shape measurement and profile measurement of an electrode: Coaxial illumination (1000x)

3D shape measurement of an electrode using the VHX Series 4K digital microscope

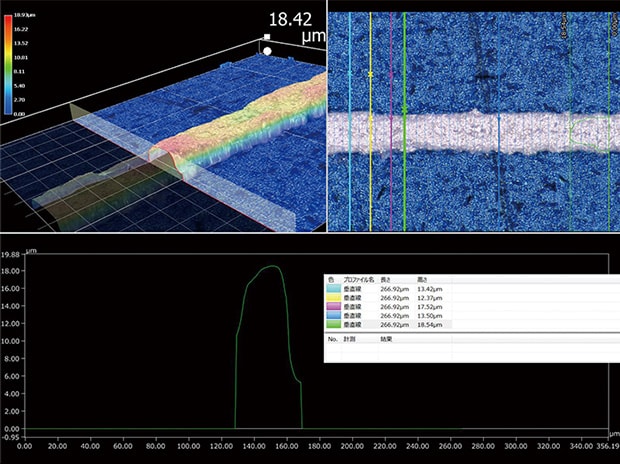

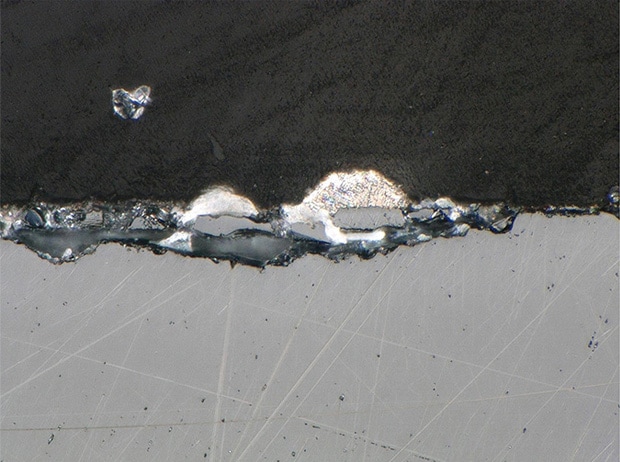

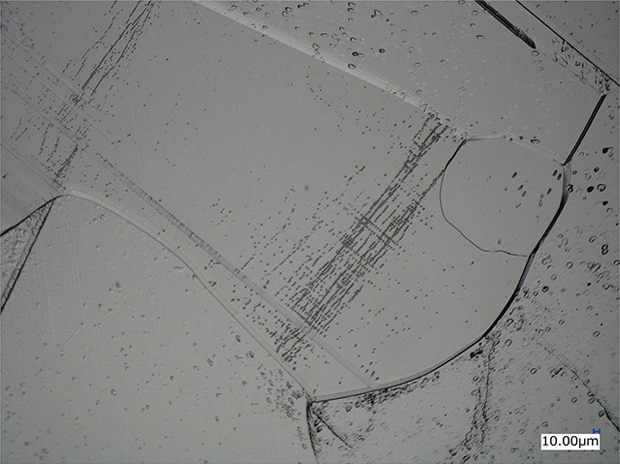

Cross-section observation of defective areas

When a polished cross section of embedded resin is observed at high magnifications using a conventional microscope, even subtle irregularities left on the surface make it impossible to bring the entire surface into focus, preventing clear observation. Preparation such as completely or almost completely evacuating the sample chamber takes a long time when observing a cross section using a scanning electron microscope (SEM). It is also difficult to detect changes in materials and to identify foreign particles mixed in the cross section because SEMs do not support color observations.

The VHX Series digital microscope has a 4K CMOS image sensor and a large depth of field enabling users to capture fully-focused color images on the entire field of view, without being affected by surface irregularities of a sample.

The fully-integrated (FI) head can automatically switch magnification from 20x to 6000x, enabling high-resolution observation of cross-section samples quickly.

Observation of defects on a cross section: Coaxial illumination (1000x)

Cross-section observation of a defective area using the VHX Series 4K digital microscope

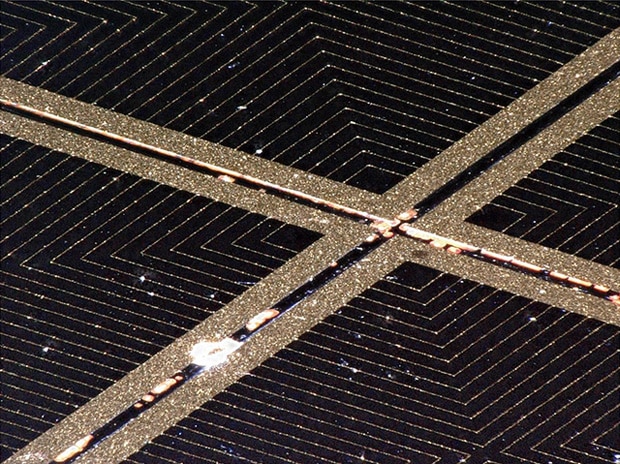

Observation of solar modules (panels)

It is difficult to observe solar modules (panels), especially subtle surface irregularities and scratches, clearly due to the glossy surfaces, mix of different colors, and low contrast.

The VHX Series digital microscope is equipped with the High Dynamic Range (HDR) function, which combines together multiple images captured at varying shutter speeds to acquire an image with high color gradation, creating high-contrast images that emphasize textures. Using the free-angle observation system and depth composition function, samples can be observed fully in focus from any angle.

Observation of a solar module (panel) using the VHX Series 4K digital microscope

HDR image + coaxial illumination (50x)

Tilted observation (depth composition) + ring illumination (100x)

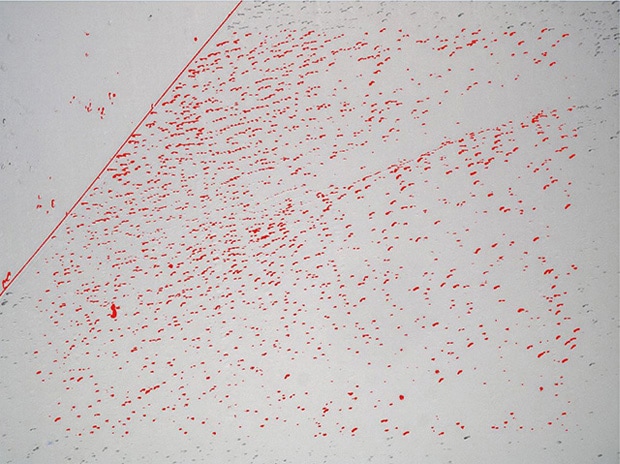

Particle counting on wafer surfaces

The VHX Series digital microscope can simplify determining the optimum lighting conditions for observation and reduce the required time using the Multi-Lighting function. The system also allows users to reproduce past lighting conditions saved with an image for other samples.

Additionally, area measurement and particle counting can be performed automatically. In this area, targets that are not required can be excluded, overlapping targets can be separated, and other useful functions can also be used.

These functions allow any operator to quickly obtain highly accurate analysis results without numeric errors regardless of the operator’s experience or level of expertise.

Particle counting on a wafer surface using the VHX Series 4K digital microscope

Before counting with coaxial illumination (300x)

After counting with coaxial illumination (300x)

We’re here to provide you with more details.

Reach out today!

A 4K Microscope That Revolutionizes Observation, Measurement, Analysis, and Evaluation of Solar Cells

The VHX Series digital microscope allows users to easily observation and capture 4K, fully-focused images. This microscope helps reduce human error when taking 2D/3D measurements and can automatically measure areas and count particles, enabling quick acquisition of numeric data and quantitative evaluation.

The VHX Series is a powerful tool that solves various problems faced by conventional microscopes and SEMs with a single unit, dramatically improving work efficiency. Additionally, Excel can be installed directly on the VHX Series which allows reports to be automatically created with the images and measurements captured. These features make workflows faster and more accurate, which is indispensable to prompt research and development of products superior to those of your competitors.

For additional info or inquiries about the VHX Series, click the buttons below.

Get detailed information on our products by downloading our catalog.

View Catalog