Laser Scanning Confocal Microscopes for Industrial 3D Surface Measurement

Key Takeaways

- Laser scanning confocal microscopes (LSCM) enable non-contact 3D surface measurement with nanometer-level Z-resolution, combining high-magnification microscopy with quantitative surface metrology.

- A confocal pinhole rejects out-of-focus light, allowing accurate measurement of rough, reflective, transparent, and low-contrast materials that challenge other optical methods.

- LSCM captures true 3D height maps and ISO surface parameters (Ra, Sa, Sz, film thickness), with data export for CAD, SPC, and quality workflows.

- Compared to interferometry, LSCM performs better on steep slopes and high-aspect-ratio features, filling the gap between interferometers and AFM.

- Applications span microelectronics, precision manufacturing, MEMS, additive manufacturing, coatings, and materials research across R&D and QA.

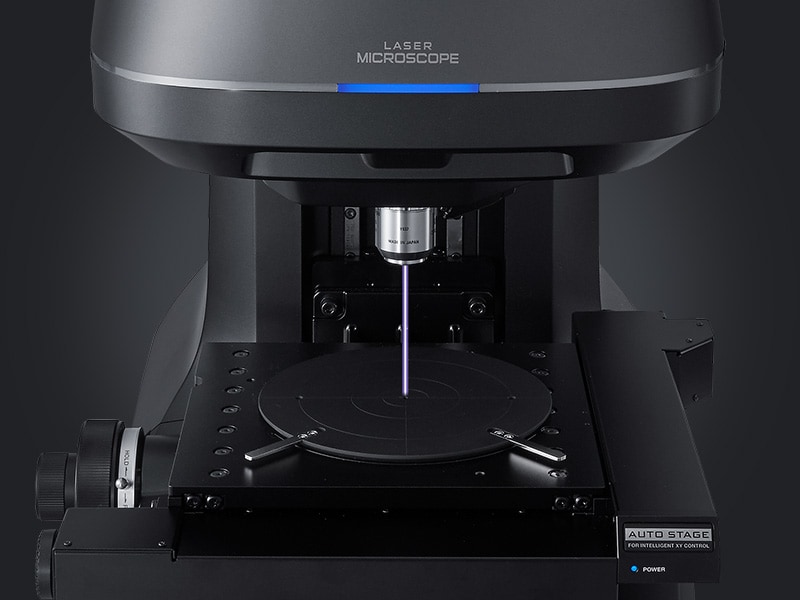

Industrial laser scanning confocal microscopes (LSCM) provide engineers with a non-contact, high-resolution 3D imaging technique capable of visualizing and quantifying complex surfaces from polished wafers to machined metals and additive-manufactured parts.

Originally developed for biological imaging, confocal microscopy has evolved into a robust, industry-grade tool that delivers nanometer-level depth precision, true 3D surface reconstruction, and material-independent measurement. For engineers evaluating optical metrology solutions, LSCM offers a versatile bridge between microscopy and profilometry, balancing resolution, accuracy, and speed. While laser scanning confocal microscopy is the technical term for these systems, you’ll often see laser microscopes, laser scanning microscopes, or similar variations to describe them.

Laser Scanning Confocal Microscopy at a Glance

| Category | Details |

|---|---|

|

Category

Technology Type

|

Details

Optical 3D surface metrology

|

|

Category

Measurement Mode

|

Details

Point-by-point laser scanning using confocal pinhole & z-axis translation

|

|

Category

Light Source

|

Details

Class II Laser (typically visible spectrum)

|

|

Category

Vertical Resolution

|

Details

Down to ~1 nm, depending on system and objective

|

|

Category

Lateral Resolution

|

Details

Between 100 to 200 nm (diffraction-limited)

|

|

Category

Depth Range

|

Details

Up to several hundred micrometers

|

|

Category

Core Principle

|

Details

Uses a pinhole to reject out-of-focus light for optical sectioning

|

|

Category

Key Advantages

|

Details

Non-contact, high depth resolution, material flexibility, steep angle detection

|

|

Category

Common Applications

|

Details

Microelectronics, precision machining, MEMS, additive manufacturing, coatings, materials R&D

|

|

Category

Ideal For

|

Details

Engineers needing high-resolution 3D surface data on reflective, rough, or transparent samples

|

|

Category

Output Data

|

Details

3D height maps, roughness parameters (Ra, Sa), layer thickness, volume, profilometry and exportable 3D data (STL, STP, etc.)

|

What Is a Laser Scanning Confocal Microscope?

Laser scanning confocal microscopy (LSCM) is an optical imaging and metrology technique that measures surface topography and microstructure by scanning a focused laser beam across a sample and detecting only the light that returns from the focal plane.

Diagram of laser scanning confocal microscope (VK-X3000 Series)

By rejecting out-of-focus light with a confocal pinhole, the system creates a sharp optical section at each depth position. Repeating this process at successive z-positions builds a three-dimensional dataset of the surface with nanometer vertical precision. For example, the KEYENCE VK-X3000 Series has a 0.1 nm vertical resolution when in laser scanning confocal mode.

In industrial applications, this principle is repurposed from life sciences into robust surface metrology, ideal for rough, reflective, and transparent materials that are challenging for other optical measurement systems due to high volumes of missing or noisy data.

Get detailed information on our products by downloading our catalog.

View Catalog

From Biological Imaging to Industrial Metrology

Confocal microscopy emerged in the mid-20th century as a solution to improve contrast and resolution in biological imaging. By adding a spatial pinhole to filter out scattered light, researchers could achieve true optical sectioning, enabling 3D imaging of thick or textured samples. Unlike materials, where the primary area of interest is just the surface, most biological samples have areas of interest throughout, so being able to segment to a particular region can be incredibly useful.

The same concept is now applied in industrial metrology. Modern LSCMs incorporate laser scanning optics, high-NA objectives, precision z-stages, and fast detectors to measure surfaces quantitatively, translating optical contrast into height data, roughness metrics, and geometric profiles.

This evolution has made confocal microscopy a critical tool for engineers seeking traceable, repeatable measurements in research, manufacturing, and quality assurance.

How Industrial Laser Scanning Confocal Microscopes Works

Laser Illumination

A focused laser beam (often blue/violet or red) illuminates a single point on the sample’s surface.

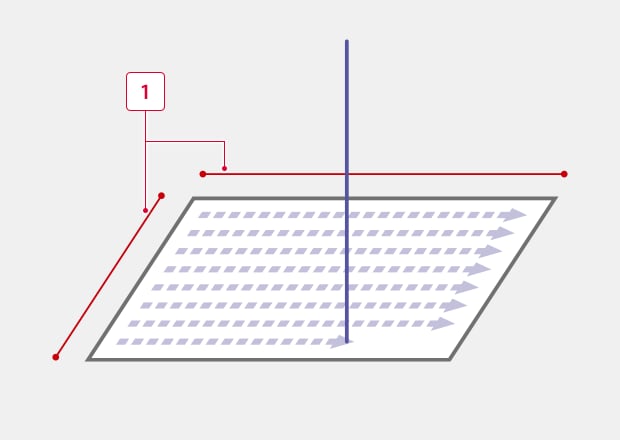

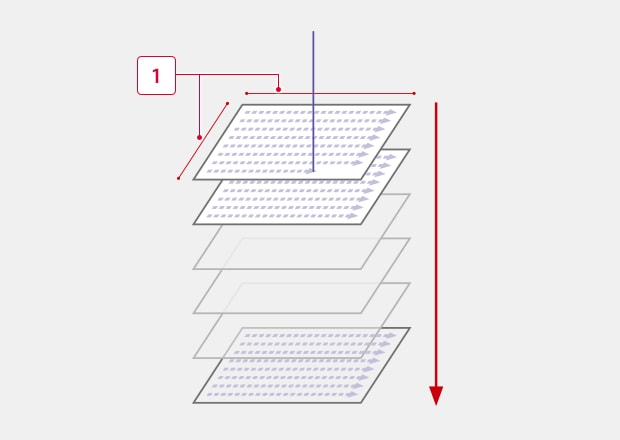

Point-by-point scanning of surface

Point-By-Point Scanning

Galvanometric mirrors or piezo scanners sweep the laser beam across the sample, creating a raster pattern that records intensity and height information pixel by pixel.

-

1Field of view

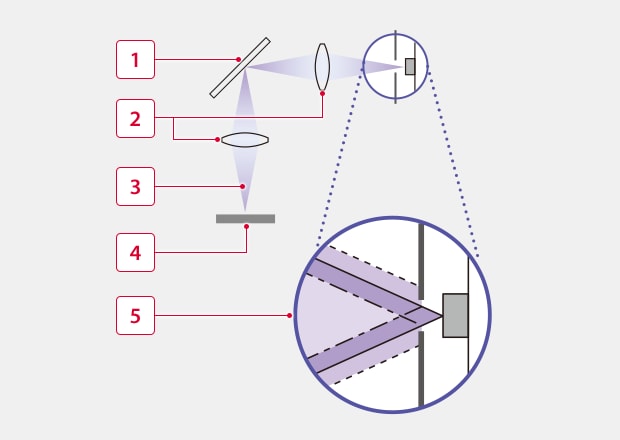

Optical imaging vs. confocal with pinhole and PMT detector

Confocal Pinhole and Signal Detection

A pinhole in front of the detector rejects out-of-focus light, ensuring that only reflections from the focal plane are measured. Our VK-X3000 Series uses a 16-bit photomultiplier tube (PMT) to amplify and detect faint signals, which ensures that you can accurately & confidently measure weakly-reflective surfaces and curved or steep angles that other systems cannot.

-

1Mirror

-

2Lens

-

3Laser beam

-

4Target

-

5Pinhole

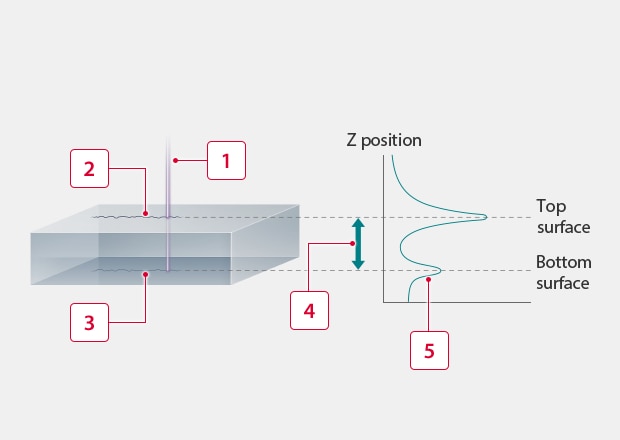

Scanning surface plane-by-plane throughout entire height range

Z-Axis Scanning

The objective or stage moves vertically to capture multiple optical sections at different focal depths.

-

1Field of view

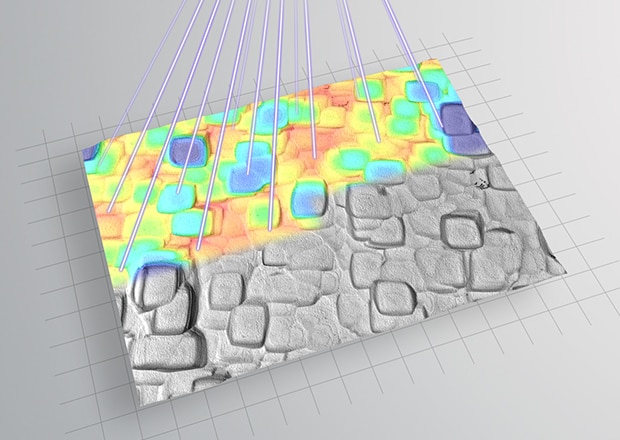

3D Data Reconstruction and Analysis

Software reconstructs these sections into a three-dimensional surface map, calculating height, roughness, and other metrology parameters.

This principle allows engineers to visualize and quantify surface structures without physical contact, preserving delicate samples while achieving sub-micron precision in three dimensions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Why Engineers Use Confocal Microscopes for Industrial Metrology

Laser scanning confocal microscopy offers a unique set of capabilities that make it ideal for precision engineering and manufacturing analysis.

Engineers often turn to laser scanning confocal microscopes when they need a metrology tool that can capture fine detail without compromising the integrity of the part they’re measuring.

The following are the advantages:

Non-Contact Measurement

Avoids damage to soft, rough, adhesive, or coated surfaces by using a laser to scan surfaces. There’s also no need for any consumable costs like probe tips that can be worn due to surface contact.

High Depth and Lateral Resolution

Enables accurate 3D profiling of fine surface features with nanometer-level Z-resolution and down to 130 nanometer lateral resolution (depending on system).

Material Versatility

Works on metals, ceramics, polymers, and transparent films. You can pretty much measure the surface of any material with an LSCM. Even surfaces with large differences in reflectivity can be imaged and measured within a single scan.

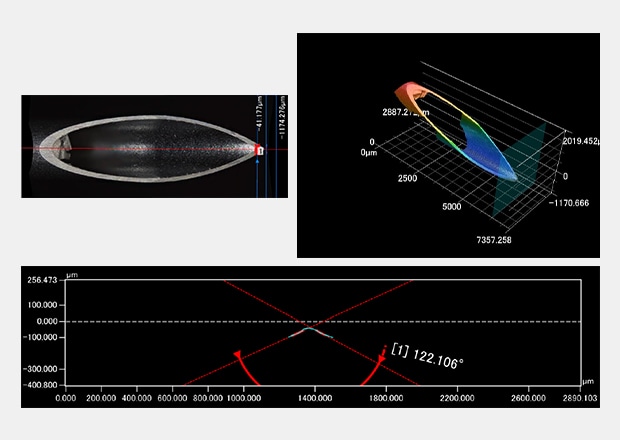

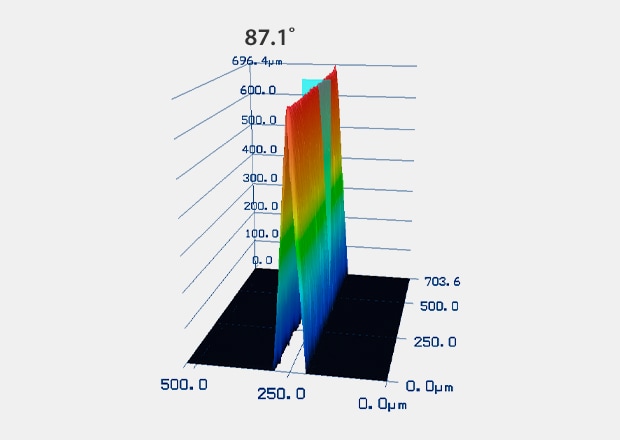

High angle of detection on razor blade edge

Steep Slope and High-Aspect-Ratio Detection

Capable of imaging near-vertical surfaces that challenge interferometers. Most interferometers lose data on slopes around 25˚ but with a laser microscope you can scan surfaces approaching 90˚.

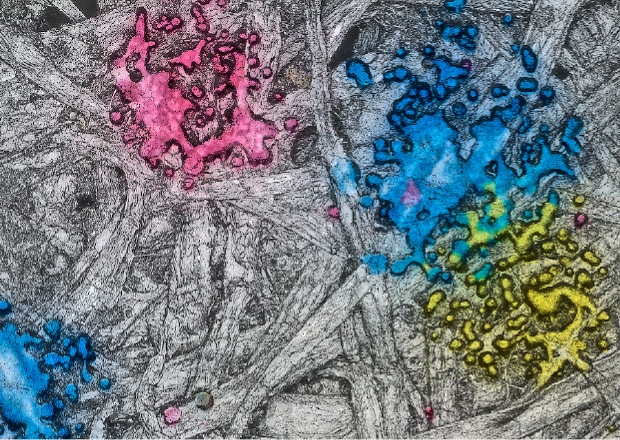

High-resolution image with true color of ink on paper

True Color Optical Microscopy + 3D Metrology

Visualizes texture and defects alongside quantitative height data. At its core, an LSCM is a microscope, so you have all of the benefits of high magnification and resolution that other measurement systems can’t replicate.

Film thickness measurement principle

Film Thickness and Multilayer Analysis

Allows inspection of coatings and multilayer structures. With the VK-X3000 Series, you can measure film thickness down to 0.1 micron and even measure surface roughness at the interface of the film and secondary surface.

-

1Laser beam

-

2Top surface shape of film

-

3Bottom surface shape of film

-

4Film thickness

-

5Intensity of reflected light

The VK-X3000 Series laser scanning confocal microscope from KEYENCE incorporates three measurement methods into a single system – laser confocal, focus variation, and interferometry – making it the most versatile metrology tool for your lab. Whether you need to measure step heights on wafers, curvature of optics, roughness on polished metals, or the thickness of transparent films, the VK-X3000 Series let’s you do all of this and more with just the click of a button. Request more info, see a demo, and test your samples to see for yourself.

Discover more about this product.

Click here to book your demo.

Common Engineering Applications

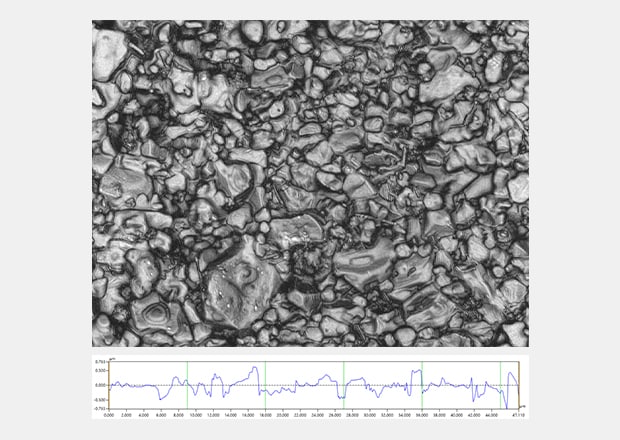

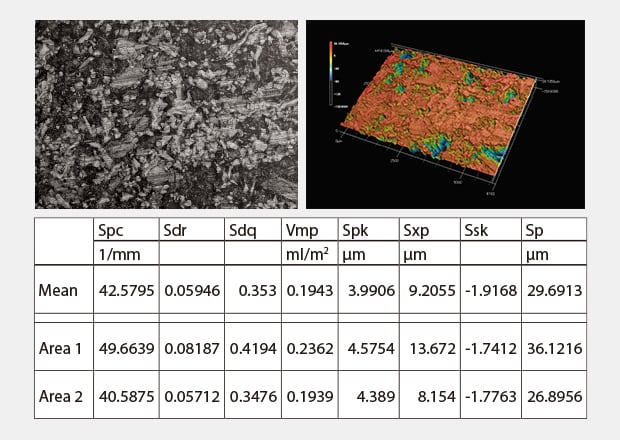

Ceramic: Line roughness measurement (6000x)

Bevel angle measurement on needle tip

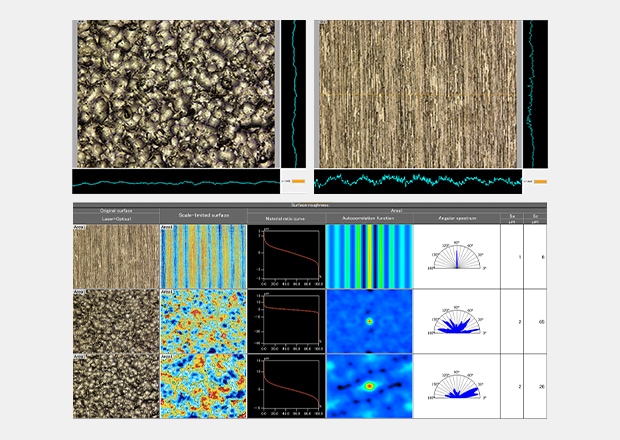

Processed metal surface: Surface roughness comparison (400x)

Brake pad wear measurement

These capabilities make LSCM a natural fit across a wide range of engineering applications. Machinists and process engineers use it to inspect surfaces for tool marks, wear, and roughness. In microelectronics, it helps evaluate solder joints, MEMS structures, and wafer topographies. Additive manufacturing teams rely on it to assess layer thickness, porosity, and overall build uniformity. Optical engineers use it to examine lens coatings and micro-optical patterns, while materials scientists employ it to study corrosion behavior, grain boundaries, and composite interfaces.

For engineers comparing surface metrology options, LSCM provides the high resolution imaging of a microscope with the quantitative accuracy of a profilometer. This combination helps fill the gap between interferometry and atomic force microscopy to provide quantitative 3D data across rough or complex surfaces that may be difficult to measure otherwise.

Curious about our pricing?

Click here to find out more.

Engineer’s Buyer’s Guide: Choosing an Industrial Confocal Microscope

Choosing the right industrial laser scanning confocal microscope starts with understanding how system specifications align with your surface measurement needs. While confocal microscopes share a common optical principle, differences in optics, automation, and software can significantly affect measurement accuracy, speed, and usability in real-world metrology applications.

- Optical Configuration and Resolution

- Laser wavelength and objective numerical aperture (NA) directly influence lateral and vertical resolution. Higher-NA objectives provide finer detail for micro-scale features, while lower magnification options increase field of view and working distance. A flexible optical configuration allows engineers to measure both fine surface texture and larger features without changing measurement platforms.

- Vertical Range and Measurement Capability

- For industrial surfaces with steps, roughness, or multilayer structures, the system must support adequate z-axis range while maintaining nanometer-scale vertical resolution. This ensures accurate 3D surface data across polished, machined, and additively manufactured parts without sacrificing measurement fidelity.

- Material and Surface Compatibility

- Industrial confocal microscopes should reliably measure reflective, transparent, and low-contrast materials. Confocal detection minimizes glare and out-of-focus noise, enabling stable data capture across mixed-material samples and challenging surface finishes.

- Automation and Throughput

- Motorized stages, autofocus, and automated stitching improve repeatability and reduce inspection time. These features are especially valuable in quality control and production environments where consistent measurements across multiple parts or large areas are required.

- Software, Analysis, and Data Integration

- Advanced analysis software converts optical scans into usable metrology data, including ISO 25178 surface parameters, step height, volume, and film thickness. The ability to export results to CAD, SPC, and quality systems supports traceable inspection and process validation workflows.

Once you have identified laser scanning confocal microscopy as the right surface metrology approach, the next step is determining how a specific system performs on real parts, materials, and use cases. At this stage, you must move beyond specifications alone and start to evalutate practical performance, ease of use, and workflow integration as some of the deciding factors.

By evaluating surface roughness, step heights, film thickness, and complex geometries on your own components, you can confidently determine whether the system meets your application, throughput, and quality requirements. Reach out to us to schedule a demo or sample test to validate performance in your exact use case.

Conclusion: Why LSCM Is Essential for Modern Manufacturing

For engineers researching metrology tools, industrial laser scanning confocal microscopy delivers an exceptional combination of resolution, versatility, and reliability. Its ability to produce quantitative 3D data on diverse materials makes it invaluable for quality control, process development, and failure analysis across industries.

As manufacturing continues to advance toward digital and AI-driven inspection, confocal microscopy will remain a key optical metrology solution that bridges the gap between microscopic visualization and precise, traceable measurement.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

A must-read document for anyone using a scanning electron microscope (SEM). This guide introduces the full extent of the capabilities of the latest 3D surface profilers, using many measurement and observation images. A rich source of information that helps you understand and solve problems you may experience with an SEM.