Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Print-and-Apply Labeler and Inkjet Printer

Printing crucial product information is an inevitable part of the manufacturing process. However, just as there are different types of products, there are also different types of printers. Not all printers are made equal, and where some excel, others are often lacking. Let’s discuss two printing technologies crucial to this process: print-and-apply labelers and inkjet printing.

Handheld Print-and-Apply Labeler/Label Printing Machine Comparison

Handheld labeling equipment is popular for its high operability and ease of use, while label printers can offer users high flexibility to change print layouts. This is why both devices are commonly used in supermarkets and other retail stores.

This section addresses some of the problems when using handheld print-and-apply labelers and label printers, as well as the advantages of using inkjet printing on labels over this equipment.

Problems with Print-and-Apply Labeler

With handheld print-and-apply labelers or a label printing machine, downtime is unavoidable when the labels run out. In addition, setting the print content and applying the label to the products must be done manually, creating more chances of operator mistakes and more work.

With an inkjet printer, the content is printed directly onto the target. This eliminates the need to physically apply labels as well as any related potential problems. Moreover, the non-contact printing method ensures stable print quality without any blurring or bleeding.

Comparing Print-and-Apply Labelers to Inkjet Printers

| Print-and-apply labelers | Inkjet printers | |

|---|---|---|

|

Cost

|

Print-and-apply labelers

Operating costs for the device are high.

|

Inkjet printers

Direct printing eliminates the need for labels, thereby reducing costs.

|

|

Productivity

|

Print-and-apply labelers

Production may stop due to problems such as separator malfunction and jamming.

|

Inkjet printers

Increase production efficiency as the labeling process can be eliminated.

|

|

Quality

|

Print-and-apply labelers

There is a risk that labels will be incorrectly affixed or may peel off.

|

Inkjet printers

Non-contact printing provides stable print quality.

|

|

Management

|

Print-and-apply labelers

Label inventory management and waste disposal can be cumbersome.

|

Inkjet printers

Content can be printed directly onto the product for easy management.

|

We’re here to provide you with more details.

Reach out today!

Inkjet Printer Application Examples

Printing with a Compact Belt Conveyor

A date-printing station can be set up easily by using the inkjet printer with a 1-m 3.3′ long belt conveyor. Because you don't have to integrate the printer and conveyor, dates can be printed reliably once a minimum space is secured. Printing is possible on both the top and sides of products.

The inkjet printer supports various products such as cartons (before/after assembly), bags (with/without contents), and bottles. Clear and reliable non-contact printing enables you to respond immediately to unexpected demand.

KEYENCE continuous inkjet printers can be customized according to the installation requirement to support any conveyor belt width and length, even if integrated constructions are required.

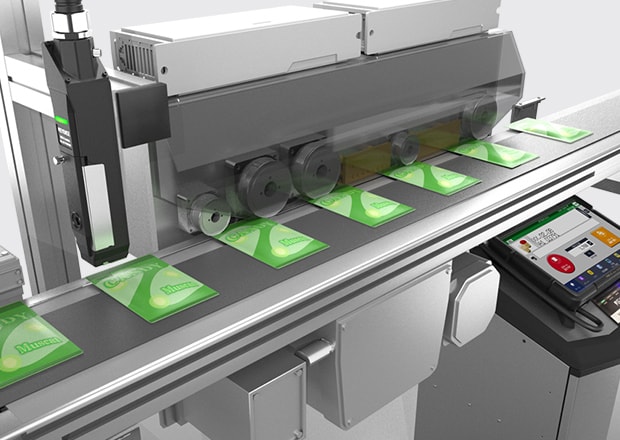

Printing During Heat Sealing

Printing can take place at the same time as heat-sealing is performed to close a bag container. Traditional contact marking has damaged this type of packaging. Inkjet printers, which use non-contact marking, eliminate packaging damage while maintaining perfect marking.

KEYENCE provides a comprehensive solution, including continuous inkjet printing systems with sensors that ensure stable detection on various film types, such as transparent films and colored films.

We’re here to provide you with more details.

Reach out today!

MEK Free Ink Is a Safer Option

Unlike traditional inks, which contain harmful chemicals such as methyl ethyl ketone (MEK), MEK Free Ink is free from these dangerous substances. This means that it not only provides a safer option for those working with ink but also has less impact on the environment.

One notable advantage of MEK Free Ink lies in its ethanol-based formulation. Ethanol, or ethyl alcohol, is a form of alcohol sourced from renewable materials like corn and sugarcane. This characteristic renders it a notably sustainable substitute for conventional inks, frequently sourced from fossil fuels.

Discover more about this product.

Click here to book your demo.

Inkjet Printing on Labels FAQs

What Distinguishes Inkjet Printers from Print-and-Apply Labeler Technologies?

Print-and-apply labelers typically rely on thermal printing, in which thermal elements within the printhead either come in direct contact with thermally coated paper or use a ribbon to label the substrate. An additional mechanism then applies the printed label/sticker to the product.

CIJ printers, on the other hand, rely on the continuous flow of electrically charged and deflected ink to print data onto a substrate. Unlike print-and-apply labelers, which typically print sticker labels, CIJ printers are a non-contact method of printing and print directly onto the product packaging.

What Are the Key Benefits of Using Inkjet Printers in Industrial Settings?

Modern industrial inkjet printers offer numerous benefits, the main one being printing speed. Some continuous inkjet printers may reach up to 1,000 m (1 km or 0.62 miles) per minute. Of course, we’re referring to a single-line text. However, these printers also can print multiple lines of text and offer uninterrupted operation up to 24 hours a day.

KEYENCE's MK-G Series offers speed, continuous operation, and advanced features that set it apart from conventional inkjet printers. These include a Smart Startup function, which automatically selects the necessary cleaning and maintenance to reduce solvent usage and running costs. This eliminates the need for skilled maintenance and service technicians.

The MK-G Series touts one of the world's only IP55-rated print heads, allowing the printer to handle even the harshest of environments. Built-in time of flight sensors monitor droplets 10 times per second to adjust for changes in ambient temperature and viscosity. This ensures consistent dots for high-quality print and reduces the frequency of downtime for cleaning.

What Are Common Challenges Associated with Print-and-Apply Labelers?

Print-and-apply printers can print large amounts of content and in high resolution. However, they face several challenges that affect their performance and overall operation. In most cases, even when they’re working like they’re supposed to, printing and applying printers still require ribbon and label reel changes from time to time, which introduces downtime in the production process. Not to mention, the cost per print is significantly higher than the continuous inkjet printers, considering the cost of both the ribbon/ink and the cost of the labels. In fact, per print, the cost of a label is usually upwards of 100x more expensive than a single continuous inkjet mark.

There are plenty of other challenges associated with printing and applying labels. For example, the print head contains thermal pins, which are subject to wear and tear, especially in industrial settings with high-volume production. Regular maintenance and printhead replacement are often costly in the long run and often lead to additional downtime.

What Role Do Inkjet Printers Play in Achieving Sustainable and Eco-Friendly Labeling Practices?

Besides their usual benefits, such as printing speed, reliability, low maintenance, and great print quality, inkjet printers are also increasingly favored for their environmental benefits.

Inkjets offer on-demand printing and often print directly onto the substrate. This eliminates the need for volume production of sticker labels, costly and only partially used ribbons, and all the waste associated with typical print-and-apply labels. The KEYENCE MK-G Series is a closed system, making it one of the most efficient and safe continuous inkjet printers on the market. The smart dock reduces exposure to hazardous materials and reduces overall use of inks and solvents. This results in a less expensive, safer, and more eco-friendly printing solution.

What Are the Key Considerations When Selecting an Industrial Label Printing Machine for Specific Manufacturing Needs?

When selecting an industrial label printing machine, key considerations mostly depend on your application or manufacturing needs. If you’re into the beverage packaging industry, continuous inkjet printers are your best bet, as they print incredibly fast and in large quantities. The ink adheres to nearly all types of solid substrates and is easy to maintain.

However, if you’re manufacturing pantyhose, the packaging line typically isn’t as fast, so you’re likely to benefit more from print-and-apply labelers, as most packaging requires a sticker label anyway. Print technology aside, other key considerations include print quality and resolution, label size, material compatibility, maintenance, and environmental considerations as well.

Are you looking to improve your printing system? Visit KEYENCE and check out our MK-G Series of continuous inkjet printers.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper