Continuous Inkjet Printers / Case Coder

CIJ for Industrial Manufacturing

Industrial manufacturing presents many challenges for date/lot coding and marking, including harsh environments, high speeds, and a variety of product surfaces.

KEYENCE's MK-G Series CIJs for industrial manufacturing are capable of meeting the toughest coding and marking demands of the industrial sector due to ease of maintenance and cleaning, physical and environmental durability, and rapid, high-quality printing.

Metal

Plastic

Ceramic

Wood products

Rubber

Plastic containers

Metal containers

Paper bags

We’re here to provide you with more details.

Reach out today!

Date Coding for Industrial Manufacturing

Construction & Building Materials

This industry requires durable products that adhere to strict safety standards. KEYENCE’s MK-G Series is IP55-rated. The head and controller can withstand dusty environments, ensuring traceability and compliance with regulatory requirements.

Click here to see "Coding on Construction and Building Materials"

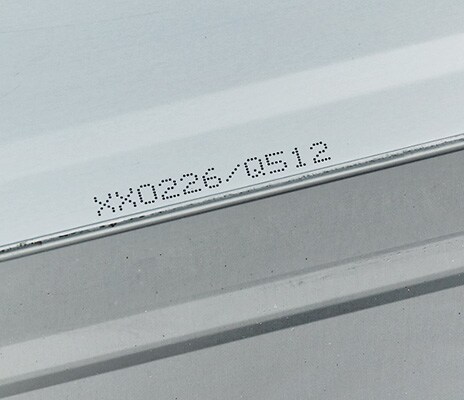

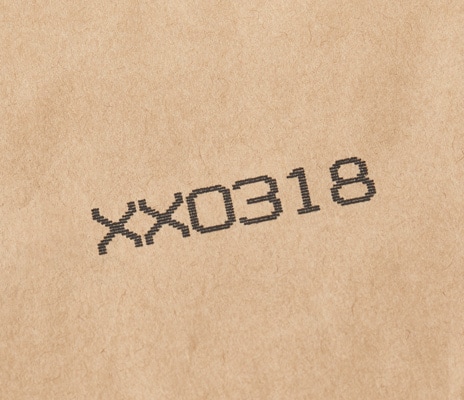

Printing example

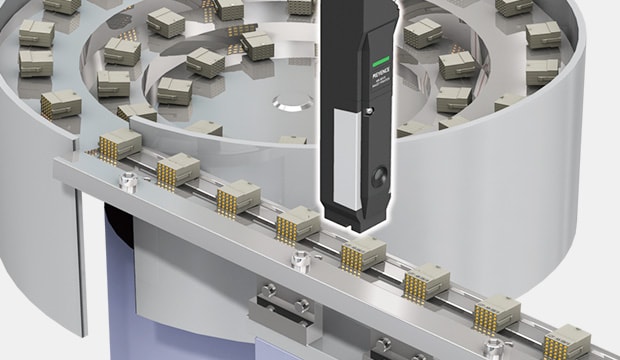

Installation example

Automotive and Aerospace

Date coding for industrial manufacturing is important for traceability and compliance. KEYENCE’s MK-G Series provides high-speed and stable marking solutions for lot numbers, serial numbers, and barcodes, even in harsh environments.

Click here to see "Coding on Automotive and Aerospace Parts"

Printing example

Installation example

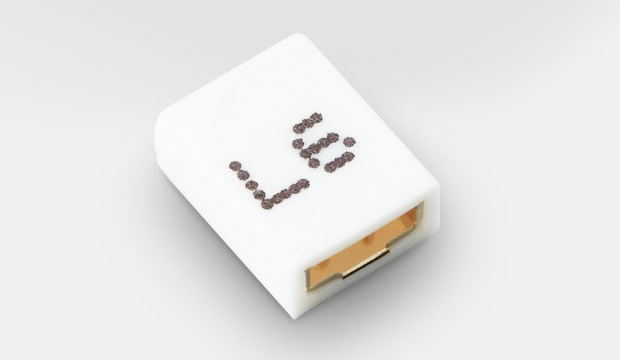

Electrical Components & Electronics

Electrical components & electronics require specific high-quality information to be displayed in small mark windows. KEYENCE CIJs integrate seamlessly into small applications, offering a micro nozzle that prints with extreme accuracy for semiconductor applications.

Click here to see "Coding on Electrical Components & Electronics Industry"

Printing example

Installation example

Wire and Cable

Printing example

Wires and cables require a variety of markings, including name, size, and rating information to meet safety regulations. KEYENCE CIJs handle continuous production without frequent maintenance, resulting in reduced downtime and costs.

Click here to see "Coding for the Wire and Cable Industry"

Piping & Extruded Materials

Adhesion and print quality is critical for marks on piping and extruded materials. KEYENCE’s MK-G series monitors breakpoints and dot condition 10 times per second to ensure high-quality codes, eliminating rework and scrap.

Click here to see "Coding on Piping and Extruded Materials"

Printing example

Installation example

Chemicals

Chemical manufacturing relies on CIJs for batch, shift, and industrial date coding. KEYENCE CIJs provide reliable coding in harsh environments, including high-temperatures, dusty and wet conditions. KEYENCE CIJs are designed to withstand these challenging conditions due to their IP55 rating an drop protection.

Click here to see "Coding on Chemical Packaging"

Printing example

Installation example

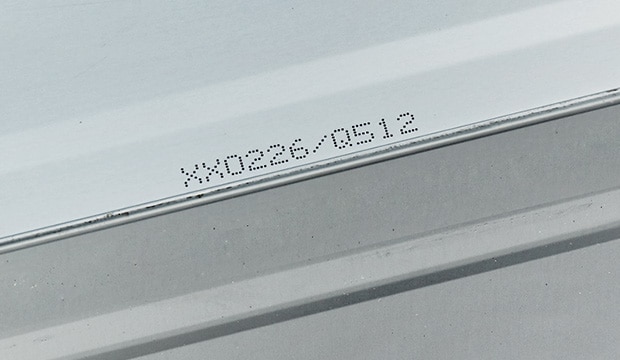

Metal

Coding on metal parts is vital to ensure traceability and quality control. The MK-G Series has a state-of-the-art automatic ink particle sensing system, ensuring the printer can maintain the best possible ink conditions and provide stable and high-quality printing on metal materials.

Click here to see "Coding on Metal Materials"

Lumber and Wood

Coding on lumber & wood products is crucial for efficient tracking and delivery of products, helping to prevent mix-ups. However, it can be challenging due to uneven textures and moisture levels.

Click here to see "Coding on Lumber and Wood Products"

Extrusions

Extrusion efficiently produces uniform items like pipes and tubes, but coding on extrusions is challenging. Lubricating oils can cause smudging, and high temperatures may affect code clarity, complicating operations.

Click here to see "Coding on Extrusions"

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs About CIJs for Industrial Manufacturing

What Are the Key Advantages of Using KEYENCE CIJs for Industrial Manufacturing?

The main advantages of CIJs for industrial manufacturing are high uptime, ease of use, durability, print quality, and reduction of running costs and human interaction (less user error).

What Features Differentiate KEYENCE’s Continuous Inkjet Printers for Industrial Manufacturing?

Continuous inkjet printers offer a wide range of inks, backup power modules, a MIL standard-compliant/impact-resistant structure, Smart Startup and event recording functions.

What Impact Do Continuous Inkjet Printers Have on Production Efficiency and Downtime in Industrial Manufacturing?

Due to IP and MIL drop-rated print heads,KEYENCE CIJs perform robustly in dusty or wet conditions and have greater productivity and performance compared to other technologies.

How Do Continuous Inkjet Printers Simplify Marking/Date Coding for the Industrial Manufacturing Industry?

Industrial inkjet printers provide non-contact printing on most substrates with high marking permanence in harsh environments.

What Are the Primary Considerations When Selecting CIJs for Industrial Manufacturing?

CIJ dimensions and ease of integration into the production line are important considerations. Throughput or marking speed is also important, and CIJ printers should also be easy to maintain and clean.

How Do Continuous Inkjet Printers Handle the Challenges of Printing Date Codes on Uneven or Curved Surfaces Commonly Found in Industrial Manufacturing?

The CIJ printer's nozzle can print on uneven or curved surfaces from a distance without touching them, preventing damage to delicate or irregularly shaped objects.

How Do Continuous Inkjet Printers Ensure Compliance with FDA and Other Regulatory Standards for Date Coding on Food Across Ondustrial Manufacturing?

Continuous Inkjet printers reliably print high-quality and accurate date and lot codes to ensure compliance with FDA and other regulator standards.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.