Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Lumber and Wood Coding Systems

Wood products move through fast, demanding environments long before they reach a builder or consumer. Clear markings support grading, tracking, and quality checks across every step of this process. A modern inkjet marking system for lumber and wood must handle rough surfaces, variable moisture, and production speeds that leave little room for error.

The MK-G Series industrial inkjet printer features non-contact printing and advanced sensors that adjust ink droplet size for clear, precise printing on wood, ensuring legible and durable product codes in varying environments.

Lot/Date Coding on Lumber and Wood Products

Lot and date coding on lumber & wood products is essential for traceability and compliance with regulations. The MK-G Series continuous inkjet printer offers flexible printing options, including sequential numbering, expiration dates, and batch codes, to meet various industry requirements. With its self-troubleshooting capabilities, the printer can also detect and alert for any errors in code printing to prevent costly mistakes.

- Dimensional Lumber

- Timber

- Plywood

- Oriented Strand Board (OSB)

- Medium-Density Fiberboard (MDF)

- Particleboard

- Hardwood Lumber

- Softwood Lumber

- Wood Veneer

We’re here to provide you with more details.

Reach out today!

Challenges in Coding and Marking on Lumber and Wood Products

Uneven Surface

Lumber and wood products have uneven surfaces, which can hinder lot/date coding on lumber & wood products. The MK-G Series addresses this by using a non-contact method of printing.

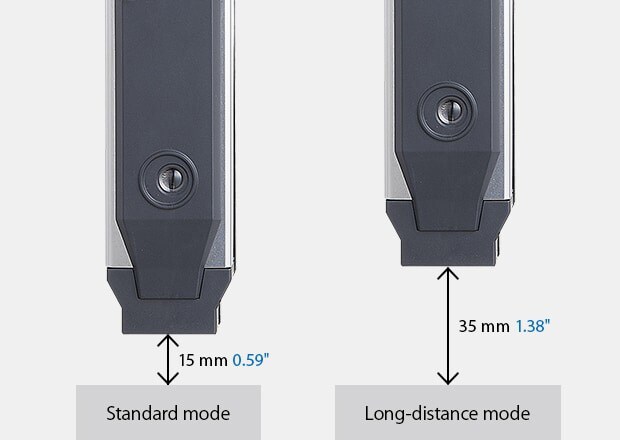

Long-distance mode:

Printing can be performed with the print head located up to 35 mm 1.38″ away from the target. This makes it possible to perform stable marking that isn’t affected by variations in the thickness of printing targets and reduces the risk of print head collision.

Fluctuating Temperatures

Temperature and humidity fluctuations can affect traditional inkjet printers, causing smudged codes. The MK-G Series uses internal sensors to help adjust the ink particles when temperature and viscosity levels change to ensure print quality consistency.

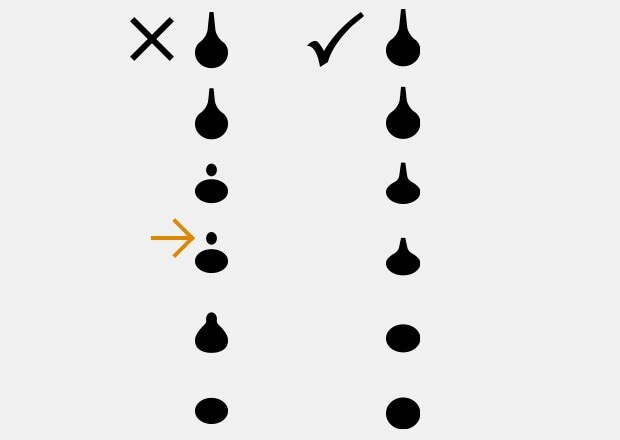

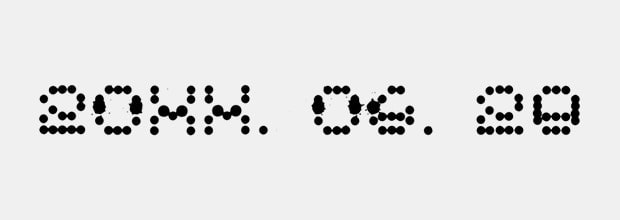

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Automatic ink particle optimization:

The surrounding environment, temperature, and ink viscosity all have an effect on the condition of ink particles and their suitability for printing. The MK-G Series senses the ink particles 10 times per second, which enables automatic adjustment to ensure the best conditions. This allows the device to provide superior printing at all times, regardless of the environment.

Less-than-optimal state of particles

Optimal particle state

Wood Dust

Lumber production facilities often have high dust levels, affecting printer performance. The MK-G Series features an IP55-rated print head design that keeps dust out, ensuring reliable printing.

Curious about our pricing?

Click here to find out more.

How KEYENCE Inkjet Printers Enhance Lumber & Wood Product Marking

Direct-to-wood industrial inkjet printer technology helps lumber mills, engineered wood lines, and pallet operations apply variable data where it matters. Wood products carry information such as grade stamps, dimensions, moisture indicators, batch numbers, and brand marks. These codes help teams track inventory, sort material, and maintain consistent production. A continuous inkjet (CIJ) printer for lumber manufacturing handles this variety without slowing the line.

KEYENCE systems place high-contrast code printing on wood surfaces with stable droplet control, even when grain patterns or surface quality shift from board to board.

Benefits of Non-Contact Inkjet Technology for Wood Manufacturing

Boards move in uneven ways, and surfaces can switch from flat to rough in the same pass. Dust and airflow add more movement around the print area. A non-contact jet stream marks from a distance, so the print head stays out of the path of changing board profiles.

KEYENCE inkjet systems respond to environmental shifts by monitoring ink conditions and adjusting droplet formation in real time. This helps maintain clear characters on absorbent surfaces and coated materials alike. Long-distance printing keeps the print head away from irregular edges while still placing sharp marks at production speed. These capabilities create predictable results across a wide range of wood substrates.

CIJ and Case Coders for Efficient Lumber Product Marking

A CIJ printer for lumber manufacturing is the primary tool for direct-to-wood codes. It applies variable data, grade information, and production details without stopping the line. Lumber and panel producers rely on this flexibility as products change in size or move between processing stages. Case coders complement CIJ printers by supporting box printing for wrapped bundles, cartons, and pallet shipments.

Discover more about this product.

Click here to book your demo.

High-Speed Inkjet Marking for Lumber Production Lines

Lumber lines run fast, and boards rarely move at a steady pace. Some pass cleanly across the conveyor, while others shift or vibrate near the print point. A CIJ printer for lumber manufacturing has to match that speed. KEYENCE systems place high-contrast code printing on wood surfaces while keeping characters sharp at full throughput. Automatic cleaning and ink control help keep the line moving during long shifts.

Industrial Marking Solutions for Wood and Lumber Processing

Different wood products create different marking needs. Dimensional lumber, plywood, OSB, MDF, veneer, and engineered panels each respond differently to ink because of porosity, density, and surface finish. KEYENCE CIJ systems adapt to these differences with stable droplet control and flexible mounting options across saw lines, panel presses, and finishing stations. Marks remain legible on furniture components, pallet parts, trim boards, and other wood goods that move through mixed environments.

Box Printing Case Coding

Lumber and wood products often ship in bundles, cartons, or palletized loads that require clear identification. When those bundles and cartons are made of cardboard, case coders (like the CC-1000 Series) provide high-resolution box printing for barcodes, date coding, lot numbers, and brand information on corrugated surfaces. This helps distribution teams scan products quickly and route shipments through warehouses without delays.

Request a Demo to See How CIJ & Case Coders Can Transform Your Wood Product Marking Process!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can KEYENCE Inkjet Printers Print on Rough or Textured Wood Surfaces?

Yes. Long-distance, non-contact printing and stable droplet control support clear codes on rough, uneven, or porous surfaces.

How Do KEYENCE Printers Provide Durability of Markings on Wood Products?

Consistent droplet formation and high-contrast inks create marks that hold up through handling, stacking, and transport.

What Is the Maintenance Schedule for KEYENCE Inkjet Printers in Wood Applications?

Automated cleaning and ink-state monitoring reduce manual maintenance, keeping production on schedule.

Can KEYENCE CIJ and Case Coders Print on Rough or Textured Wood Surfaces?

CIJ handles the wood itself, while case coders mark packaging and boxes. Both offer reliable performance on their intended materials.

How Does the Case Coder Improve Box Printing for lumber?

It produces sharp, readable codes on cartons and bundle packaging, supporting fast scanning and accurate routing in distribution.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper