Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Case Coding on Folding Cartons

Case coding on folding cartons requires clear, consistent coding on these boxes, as it’s necessary for traceability, brand protection, and operational efficiency. Case coding folding cartons with the right technology means fewer labeling errors, faster changeovers, and better inventory control. But not all cartons are the same, and not all inkjet coding solutions can handle them. For raw paper-based substrates, such as uncoated cardboard and corrugated cardboard, direct printing with a high-resolution case coder offers the most reliable and cost-effective solution.

Compatible Materials for Case Coding

Folding cartons used in end-of-line packaging are typically made of raw paperboard, corrugated fiberboard, or cardboard—materials well-suited for high-resolution case coding. These substrates are porous, allowing ink to bond cleanly without smearing. However, cartons treated with coatings like varnish or UV-cured overprints, or other surfaces like PET and glass bottles, are non-porous and incompatible with KEYENCE CC-1000 Series ink. The KEYENCE CC-1000 Series is specifically designed for use with untreated cartons.

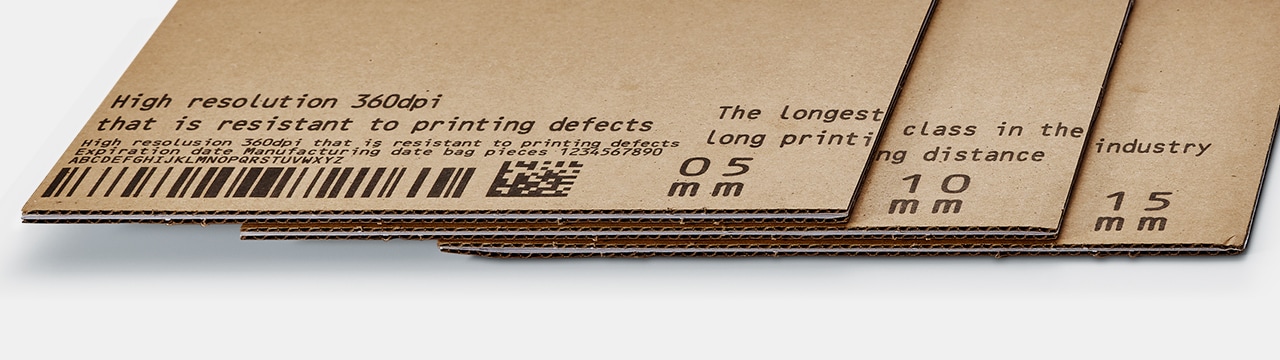

Printing example

We’re here to provide you with more details.

Reach out today!

Why Choose Case Coding for Folding Cartons?

Accurate code placement supports traceability and compliance for industries (like food, pharmaceuticals, and cosmetics) that rely on lot codes and barcodes to comply with regulations and maintain brand integrity. Direct case coding eliminates the need for preprinted boxes, reducing labeling errors and enabling on-demand printing, as well as easier line changeovers.

Why Corrugate Works Best for Coding

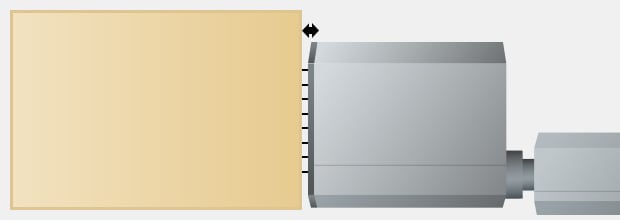

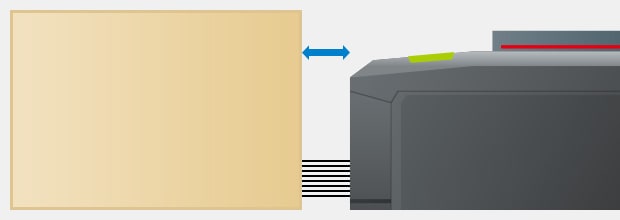

Corrugate and raw cardboard provide a stable surface for ink absorption, reducing smudging and ink transfer. The CC-1000 Series’ 0.6-inch throw distance and 360 DPI resolution deliver reliable prints without head contact. This minimizes splashback and protects the printhead from damage.

Conventional models (short working distance)

CC-1000 Series (long working distance)

Curious about our pricing?

Click here to find out more.

Optimizing Print Quality on Raw Paper Surfaces

Zero print distortion

The CC-1000 Series’ multi-sensor unit tracks conveyor speed, distance, and vibration to maintain consistent output, and automatic adjustments provide crisp barcodes and data codes, even when line conditions vary.

Typical Applications of Case Coding on Folding Cartons

Folding cartons are commonly used with secondary packaging coding for cosmetics, personal care products, pharmaceuticals, and electronics. These boxes often carry barcodes, lot numbers, and date codes for tracking and compliance. The CC-1000 Series supports accurate, high-speed printing in these environments without added steps or downtime.

How Our Case Coding Solution Works on Folding Cartons

The CC-1000 Series combines high-resolution printing with easy integration. Its long throw distance avoids carton contact, while the built-in inspection camera verifies every print. Maintenance is fast with a head core that is replaceable on-site when needed and tool-free cleaning. It’s a reliable, operator-friendly solution for folding carton lines.

Ready to improve your folding carton coding quality? Learn more about the CC-1000 Series today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Why Can't the CC-1000 Series Print on Glossy or Coated Cartons?

Coated cartons are non-porous, causing ink to smear. The CC-1000 Series only prints on raw, untreated cardboard.

Can the CC-1000 Series Integrate with Automated Packaging Lines?

Yes. Its sensors and inspection system integrate easily with conveyors and automation setups.

What Type of Information Can Be Printed on Folding Cartons Using the CC-1000 Series?

Expiration dates, lot numbers, barcodes, QR codes, logos, and serialized data.

How Does Printing on Cardboard or Corrugated Cartons Benefit Packaging Operations?

It reduces label use, simplifies inventory, and improves traceability with on-demand printing.

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper