Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

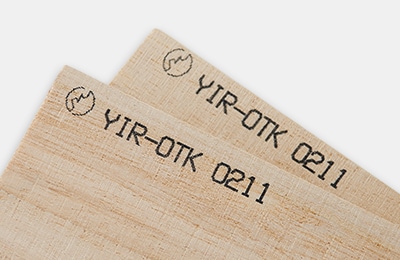

Serial Number Printing on Building Materials

When it comes to direct printing and coding for tracking and traceability, there is no tougher environment than that of building products manufacturers. From wood shavings, cement dust, fiberglass shavings, and countless others just surviving in these environments is a tall order for most printers. The range of materials used, and the barrage of dust and particulate makes consistent print an afterthought, just keeping the nozzle from clogging is a start.

Many of these production areas are also open air with fluctuating temperatures and humidities, this makes ink and dot consistency as well as viscosity control impossible to keep up for conventional continuous inkjet printers. Skilled workers are also not jumping at the chance to brave these environments, so labor intensive and maintenance heavy printers relying on skilled staff are often left neglected.

KEYENCE’s direct sales method and our experience with difficult manufacturing environments helped with the design of the MK-G Series continuous inkjet printer. Designed from the ground up to be able to withstand anything building product manufacturing and can throw at it while delivering consistent high-quality serial number printing with minimal maintenance.

We’re here to provide you with more details.

Reach out today!

How the MK-G Series Excels in Harsh Building Product Environments

Here is a breakdown of how the MK-G Series can flourish and still print perfectly on even the most challenging building product applications.

Tough

Two major industry firsts were incorporated into the structural design of the MK-G Series to be more durable than any other building product printer.

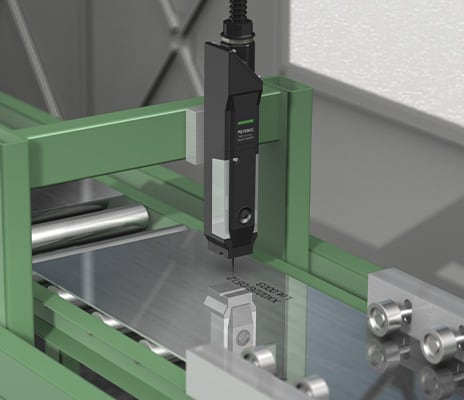

1. IP rated head – other conventional CIJ offer IP ratings for the controller but fail to protect the most important and delicate part of the printer – the head. IP55 rated and able to handle all the dust and debris building products have to offer.

2. Next, and most importantly, the head is MIL drop rated. The head and reinforced umbilical can withstand impacts and drops without skipping a print. The touch screen is also MIL rated eliminating worries of damage from stray pipes, boards, or operator drops.

Reliable

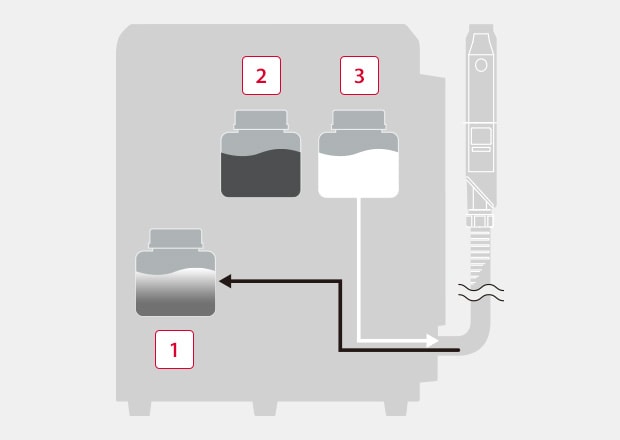

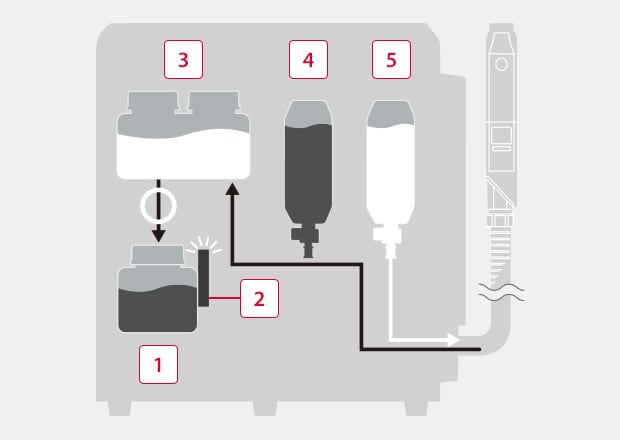

The MK-G Series has a 4th tank built in for superior viscosity management. This tank conserves solvent usage and acts as a buffer for the ink in the main tank.

Conventional

When washing is performed, the ink viscosity decreases.

-

1Main tank

-

2Ink tank

-

3Solvent tank

MK-G Series

The conditioning tank is used for temporary storage to prevent dilution of the ink.

-

1Main tank

-

2Viscosity sensor

-

3Conditioning tank

-

4Ink cartridge

-

5Solvent cartridge

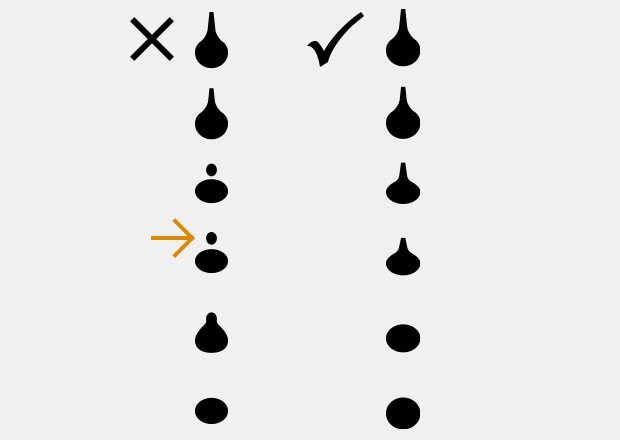

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

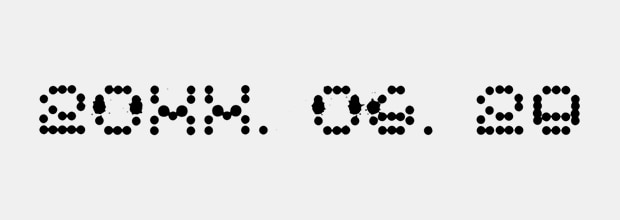

The buffering of ink works hand in hand with a KEYENCE industry leading sensor in the head to manage break point. This means even with temperature changes or high humidity dots are actively adjusted in real time. The break point or dot quality of the MK-G Series is adjusted 10 times per second for flawless print and then less frequent cleaning and maintenance.

Less-than-optimal state of particles

Optimal particle state

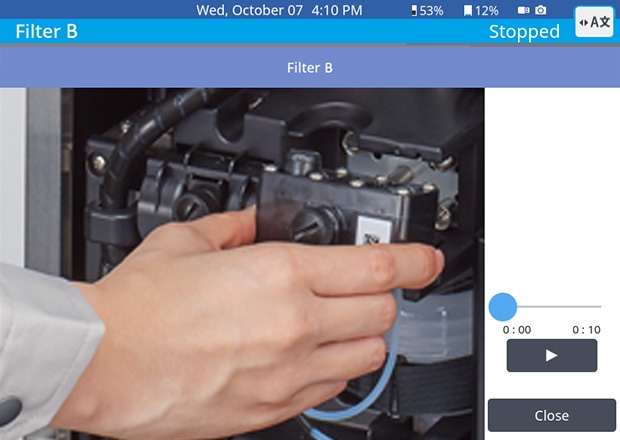

Maintenance Free

Other factors also contribute to the limited maintenance requirements. More specifically, any maintenance required can be done by anyone, no special tools required, with intuitive walkthroughs and videos for part replacement and troubleshooting. No more skilled labor or service contracts are needed to keep building product serial printing running smoothly.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can the MK-G Series Handle Extremely Dusty Environments?

Yes, KEYENCE IP55 rated continuous inkjet printer can still print high quality codes on pipes, insultation boards, metal beams, and more even when completely covered in dust. The print head is IP rated as well leaving less to worry about.

What Specialized Tools and Skills Do Maintenance Workers Need to PM KEYENCE Printers?

All maintenance on the MK-G Series can be done by anyone with commonly found tools. Standard part replacements are tool free, replaced using only hand screws. Simple video tutorials and onboard diagnostics take the guess work and skill out of inkjet printer maintenance and lot coding for building product manufacturing.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper