Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

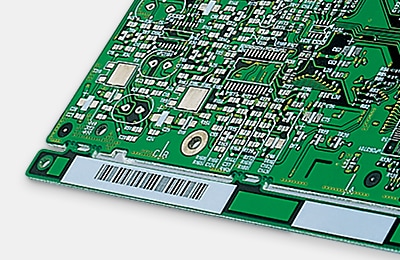

Serial Number/2D Code Printing on PCBs

Printed circuit boards or PCBs are critical for the functionality of a wide range of products today. Tech products in the consumer electronics industry of course need PCBs, but the use is so much more widespread across the automotive industry, medical devices, Lighting to name a few. The broad and high-volume use cases for PCBs means that tracking and traceability is extremely important for manufacturers in all these industries.

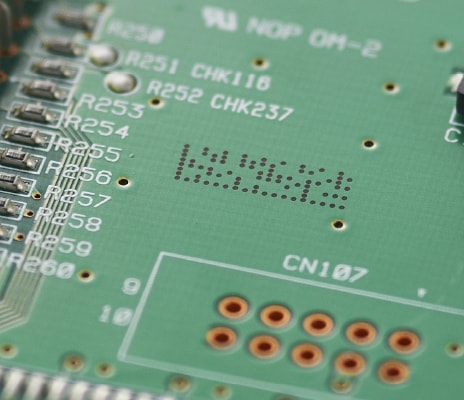

Printing or marking serial numbers or lot information as well as 2D bar codes on PCBs are needed for support, regulatory compliance, quality assurance, and of course product recalls. This traceability can be embedded into the PCB, added as an RFID chip, or commonly and most flexibly marked with an industrial inkjet printer or laser. Non-contact continuous inkjet printing is an effective marking method allowing for 2D codes and serialization to be printed on PCBs at any point in the manufacturing process.

We’re here to provide you with more details.

Reach out today!

Challenges of Marking PCBs with Traditional Printing Methods

Given the nature and size of PCBs, finding a reliable and high-quality solution for printing 2D codes or serial numbers poses some hurdles. The board itself is often maid of a woven fiberglass or epoxy composite. These materials are often flame resistant, so laser marking isn’t always effective. This left ink-based printers which are often messy, lower resolution, and not a great fit for the high-tech environment strictly controlled for PCBs manufacturing.

LED

Dry battery

Circuit board

Capacitor

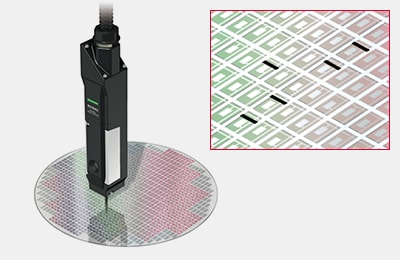

KEYENCE had such limitations in mind, being a leading laser and continuous inkjet manufacturer, listened to customer needs and released the MK-G1100 small character continuous inkjet printer perfect for marking on tiny PCBs, wafers, transistors, and other tiny and precise electrical components.

Small character type MK-G1100:

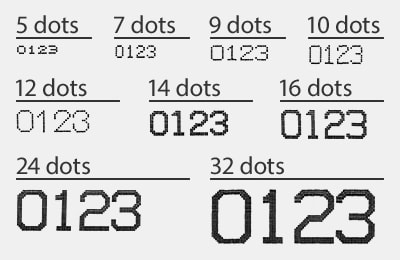

5-32 dots

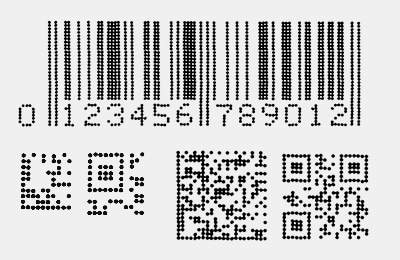

Barcode / 2 codes

PCB

Curious about our pricing?

Click here to find out more.

Why the MK-G Series CIJ Is Ideal for High-Precision PCB Marking

The following specifications make the MK-G1100 CIJ a perfect solution to printing 2D codes and serialized data on PCBs.

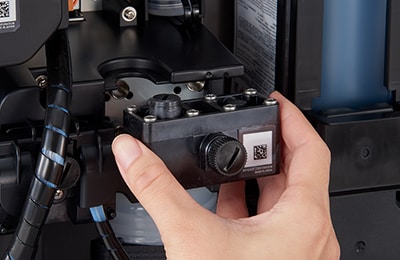

Closed System with MK Smart Dock

From an environmental standpoint, inkjet printers often are messy and unsanitary for PCB printing, but the MK-G Series has a sealed cartridge system where a needle punctures and suctions ink and solvent. Drains and part replacement are also modular and eliminate risk of ink exposure and spills.

Most importantly, daily PMs are completed and mostly contained inside the industry first MK Smart Dock. Print head cleaning is completed at the push of a button, with little exposure to volatilized chemicals, and contained in the docks waste bottle. There is no other continuous inkjet on the market that is as clean to operate and safe for operating.

Ink & solvent cartridge system

One-touch replacement

Connected-cartridge Draining

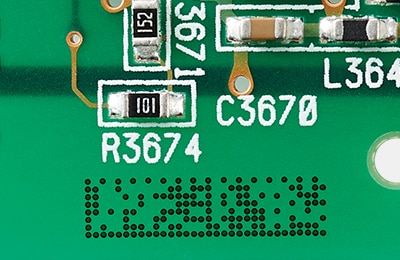

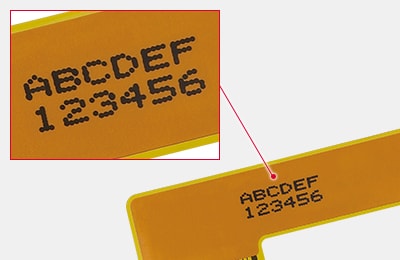

Print Resolution

Of course, addressing the challenge of dot control for continuous inkjets is going to be the most important part of printing on PCBs. Ink splatter and variability results in poor quality or failed 2D data matrices and bar codes. Our patented 40-micron ceramic nozzle allows for text sizes as small as .6 mm 0.02" and 2D data matrices printed at only a few mm (depending on content) with perfect dot quality.

Working in Tandem with this, a KEYENCE leading feature, our ink particle optimization sensor adjusts dot break point 10 times per second as needed to ensure consistent codes on all PCBs. Last, and most technical, an updated and unique design for just the MK-G1100 small character PCB printers head and deflector plates reduces interference from electrostatic forces. The microscopic, charged ink dots can repel each other when attempting to print the smallest of serial numbers and 2D codes on PCBs and this is mitigated by a cutting-edge design.

-

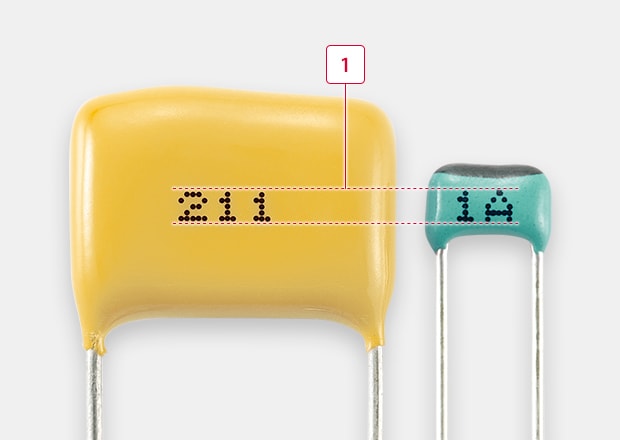

1Character height 0.6 mm 0.02"

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Types of Information Are Commonly Printed on PCBs?

Extensive information from material composition, conformal coating type, UDI, manufacturing date and location, and many more can all be encoded into and printed into a small 2D data matrix on PCBs.

How Small Can the MK-G1100 Series Print on PCBs?

A single line of text can be as small as .6 mm 0.02" tall and up to 7 mm 0.03". Up to 6 lines of .6 mm 0.02" tall text can be stacked. For 2D codes, sizes depend on the content required and can be as small as a few mm.

How Small Can the MK-G1100 Print on PCBs?

A single line of text can be as small as .6 mm 0.02" tall and up to 7 mm 0.03". Up to 6 lines of .6 mm 0.02" tall text can be stacked. For 2D codes, sizes depend on the content required and can be as small as a few mm.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper