Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Date Printing on Packaging Film: Best Practices

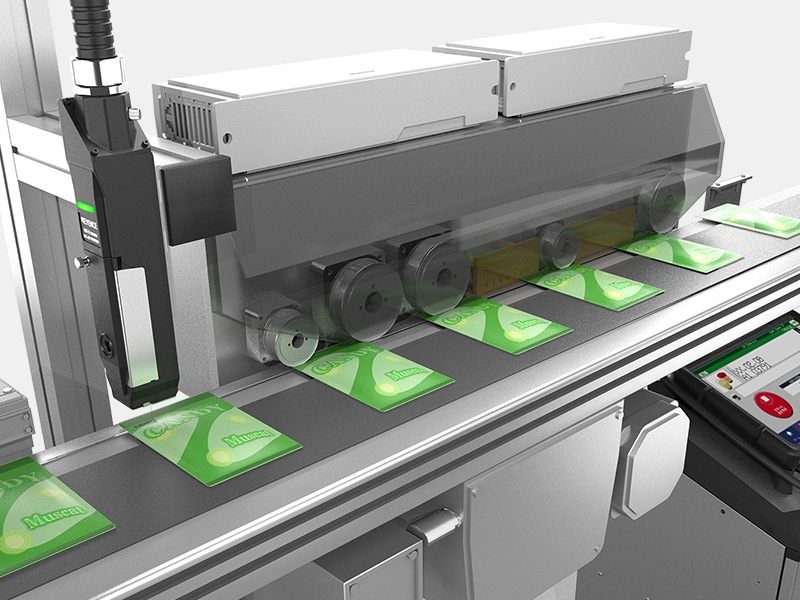

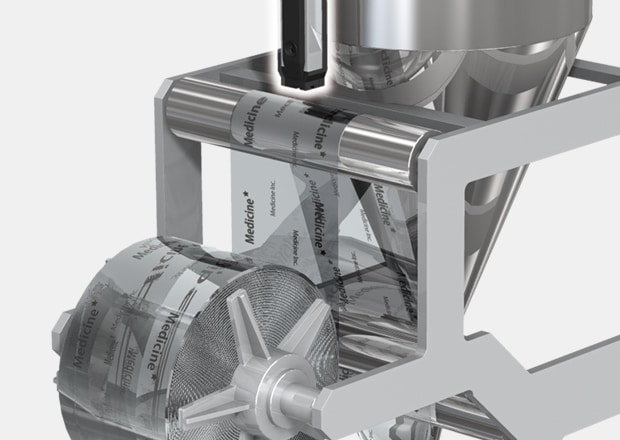

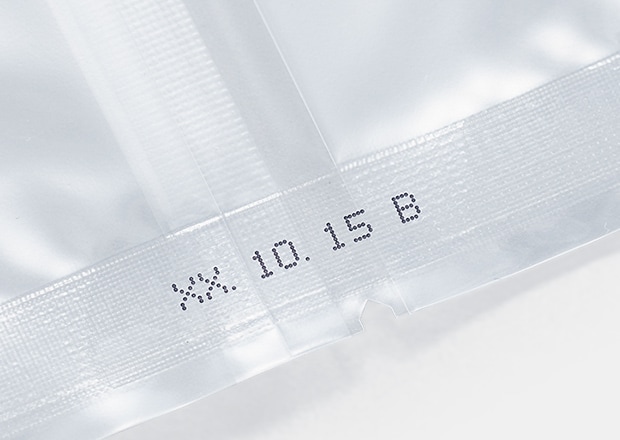

Packaging film is printed with a CIJ mounted on a pillow-type packaging machine, a heat sealer, or a cup sealer during the packaging process. CIJs can be used on high-speed lines and eliminate problems such as damage to films that are usually caused by the contact method of printing.

Challenges of Printing on Flexible Packaging

Flexible packaging introduces variables that most printers aren’t built to handle. Materials like plastic film, foil laminate, or coated paper don’t sit flat, hold tension consistently, or absorb ink predictably.

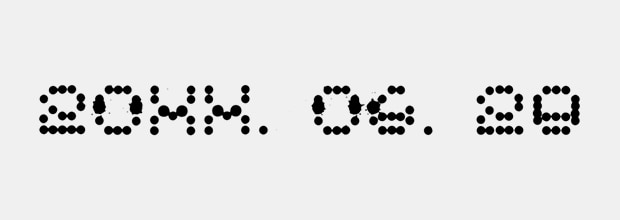

Wrinkling, curl, and static charge all interfere with legibility. Add in line speeds approaching 300 meters per minute, and even minor alignment or adhesion issues can lead to unreadable codes. These aren’t rare edge cases either; they’re daily challenges faced by production teams where the traceability of a product is non-negotiable. For many, date code printing on film packaging is the single most error-prone part of the process.

We’re here to provide you with more details.

Reach out today!

How CIJ Technology Solves Date Coding Challenges

Continuous inkjet (CIJ) printers are engineered for unpredictability; they apply ink without contact, and they’re unaffected by film movement or surface variations. That gives them a critical edge on packaging lines running pouches, sachets, or flow wraps. Unlike technologies that rely on flat, stable targets, CIJ printers handle motion, speed, and surface shift without skipping a beat.

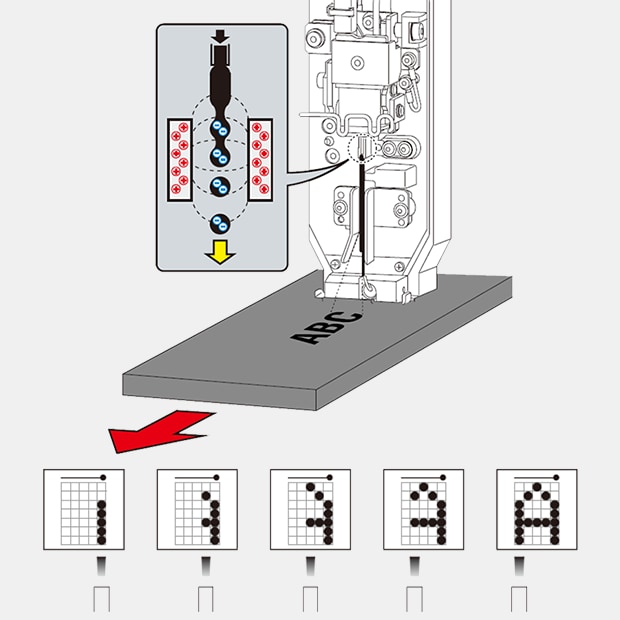

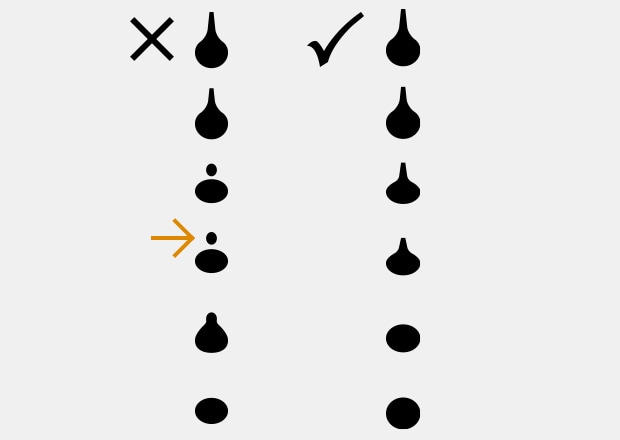

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

The MK-G Series from KEYENCE takes this further with the ability to sense ink viscosity and environmental conditions in real time and adapt accordingly. Whether the production line is cold and dry or warm and humid, the print remains stable. Printhead distance can vary without sacrificing clarity, and cleaning cycles are automatic, triggered by actual need, not fixed intervals. For production teams, that means more consistent uptime with fewer manual resets.

Less-than-optimal state of particles

Optimal particle state

Ideal Industries for Film Date Printing

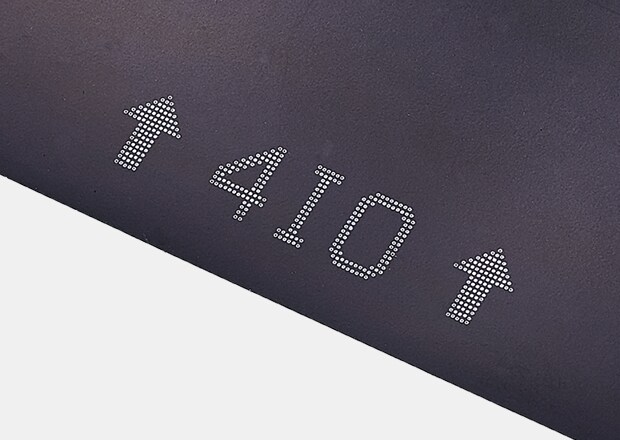

CIJ printers for packaging materials are used across sectors where lightweight films are preferred. Food manufacturers code flexible packaging for cheeses, snack foods, and portioned meals. Personal care brands print expiration data on sample sachets and soft-sided refill packs. In pharmaceuticals, small-format pouches and foil wraps require precise lot and batch codes for compliance.

In each case, reliable, high-speed coding supports traceability while keeping lines moving. This level of industrial date coding isn’t just about aesthetics but also about meeting standards without creating bottlenecks.

Curious about our pricing?

Click here to find out more.

Selecting Inks for Different Packaging Films

Every film substrate reacts differently to ink. A porous paper laminate requires a formulation different from that of a high-gloss poly wrap. In many cases, standard inks flake, smear, or simply won’t bond. Choosing the right date code printer for film means choosing one with built-in ink flexibility.

The MK-G Series supports strong-adhesive inks for slick or low-energy surfaces, as well as pigment-based inks like yellow and white for high-contrast visibility. It even offers MEK-free models. This flexibility ensures consistent film packaging marking across diverse product lines while minimizing downtime.

Why Choose CIJ for Printing on Packaging Film?

CIJ printers keep pace with high-speed lines, can code across curved or shifting surfaces, and deliver the kind of reliability packaging teams need to scale. High-resolution continuous inkjet printing keeps expiration dates sharp and legible, even under less-than-ideal conditions.

With a system like the MK-G Series, teams gain added control, automated upkeep, and the adaptability required to meet modern line demands.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can CIJ Printers Print on Different Types of Packaging Films?

Yes. CIJ printers like the KEYENCE MK-G Series handle a wide range of films, glossy, porous, or laminated, thanks to their ink flexibility and strong adhesion options.

Why Is Continuous Ink Jet Printing Ideal for High-Speed Packaging Lines?

CIJ is non-contact and built for speed. It prints clean, legible codes even on moving or curved films up to 300 m/min without smudging or skipping.

What Maintenance Is Required to Keep CIJ Printers Running Efficiently on Film Lines?

There is minimal maintenance required. The MK-G automates cleanings based on actual need, not a timer. It monitors ink and environmental conditions to prevent clogs and reduce downtime.

Can CIJ Printers Integrate with Automated Packaging and Traceability Systems?

Yes. CIJ systems support PLC integration, enabling automatic code changes, real-time control, and traceability for food, pharma, and more.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper