Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Large-Character Inkjet Printing on Pallets & Lumber

From traceability and inventory to regulatory compliance and export readiness, clear and legible codes support lumber traceability on wooden pallets in inkjet pallet printing. This is essential for keeping production and logistics moving smoothly and without disruption.

Why Large-Character Printing for Pallets Is Critical

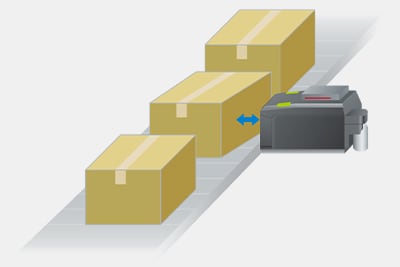

Coding pallets and lumber is essential for tracking, compliance, and sorting across facilities and shipping routes. Clear, scannable marks, such as IPPC stamps, lot codes, or barcodes, help support a smooth inventory flow and prevent costly mix-ups. Direct marking reduces reliance on preprinted labels, which can detach or fail in outdoor or high-impact environments. Large-character inkjet pallet printing helps operators apply codes in-line with production, without halting operations or switching packaging stock.

We’re here to provide you with more details.

Reach out today!

Challenges in Printing on Wood Pallets and Lumber

Wood substrates aren’t uniform. The grain structure varies across different boards. Surface roughness, knots, and resin pockets affect how ink settles and adheres. Moisture content shifts with humidity. Conveyor vibrations and shifting product height increase the risk of nozzle damage or misaligned prints. Dust from sawing or sanding can also interfere with print quality. All of these factors make printing on pallets and lumber more complex than coding on cartons or flat cases.

Adapting Inkjet Printers to Wood Surfaces

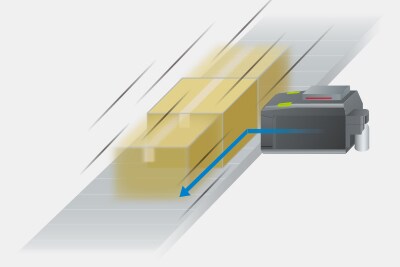

Large-character inkjet printing systems designed for industrial use can overcome these obstacles by maintaining distance from the target while delivering bold, high-contrast text. Their ability to cover wide marking areas allows for oversized codes that remain readable even after stacking, handling, or wear and tear. Compatible ink types provide quick dry times on porous wood and maintain legibility without bleeding. This makes large-character inkjet lumber printers well-suited for coding dimensional lumber, hardwoods, and shipping-grade pallet stock, eliminating the need for surface preparation.

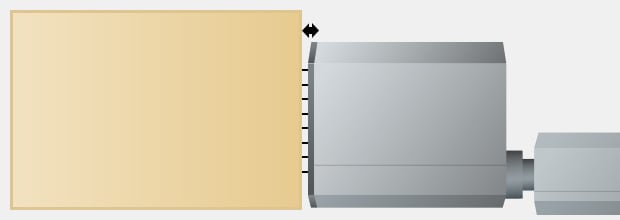

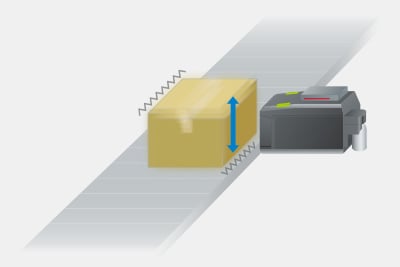

Conventional models (short working distance)

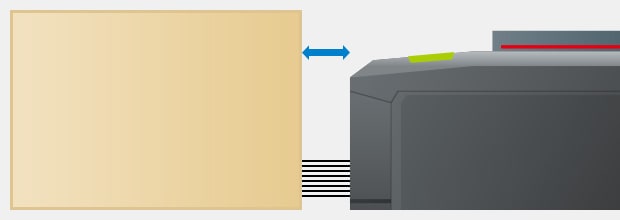

CC-1000 Series (long working distance)

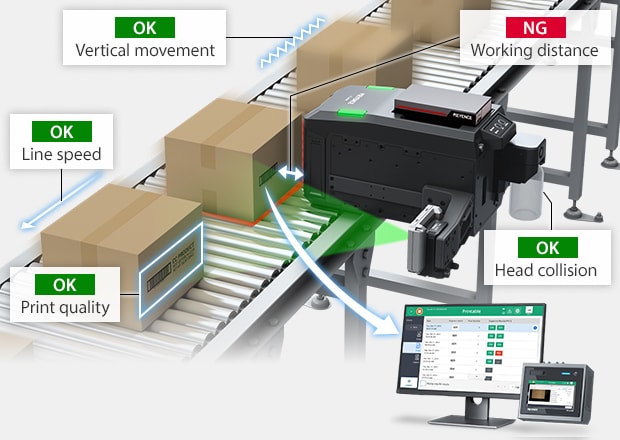

MSU Role in Distance & Surface Variability

Print quality depends on real-time awareness of what’s happening at the line. Multi-sensor systems play a key role in compensating for product variability. These sensors monitor distance from the substrate, vertical movement, and vibration to keep the codes centered and aligned, even if the pallet slats are warped or uneven. These systems continuously adjust for environmental and mechanical fluctuations to reduce print errors and prevent wear from unnecessary head contact.

Long working distance

Speed tracking

Vertical movement detection

Curious about our pricing?

Click here to find out more.

Printer Setup for Rough Lumber

Operation status visualization

* Example using multi-sensor unit

Setting up a wood pallet coder is simple and doesn’t require a complicated process. These systems are designed for fast installation, easy adjustments, and require minimal training. Ink systems are sealed and self-contained, limiting mess during maintenance. Many units also support remote monitoring or batch updates across multiple lines, enabling teams to maintain production continuity even as product sizes or requirements change.

Why Large Character Inkjet Is Ideal for Non-Case Printing

Surfaces like pallets, boards, and fiber drums pose challenges that traditional case coders aren’t built to handle. Surface variation, outdoor exposure, and uneven spacing call for a marking system that doesn’t rely on adhesion or label stock. Large-character inkjet systems can mark directly onto raw, treated, or kiln-dried lumber without surface preparation. Codes remain legible after transport, stacking, and exposure to weather, making these systems a natural fit for yards, mills, and logistics centers.

In specialized applications, the MK-G Series can be used to mark nail punching locations on heat-resistant boards or panels. Its non-contact continuous inkjet method enables consistent placement across thermally stable substrates without risking damage or slowing the line.

See how large-character inkjet printing performs on your lumber or pallet line. Request a pallet coding demo today.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Do Inkjet Codes Withstand Outdoor Pallet Use?

Specialized inks maintain visibility despite exposure to moisture, sun, or abrasion during handling.

Does Wood Grain Variation Affect Print Clarity?

Wood grain can impact print clarity, but high-resolution printing preserves code legibility across wood types.

Can MSU Detect Head Offset on Uneven Pallets?

Yes. The system adjusts for product movement or vibration to keep the codes properly positioned.

Can Large Character Inkjet Printers Handle High-Speed Production Lines?

Yes. These systems maintain stable output and legibility even at high throughput rates.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper