Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Inkjet Coding on Paper Bag Packaging Machines

Inkjet printers are common on flexible packaging lines, but paper bags introduce unique variables like porous surfaces that can cause ink to bleed, and movement on conveyors often disrupts print position. Maintaining scan-grade codes in this environment takes more than basic triggering; it requires precise speed tracking, stable integration, and systems that adapt in real time without slowing the line.

Key Challenges with Paper Bag Printing

Paper bag materials absorb ink unpredictably, especially those made from uncoated kraft or fiber blends. Other challenges, like misalignment, bag shifting, and uneven surfaces, cause print inconsistencies, particularly on lines where bags are coded flat before filling. These problems impact paper bag traceability, risking unreadable lot codes, smeared barcodes, or failed compliance checks.

Without real-time compensation, even minor variations in position or angle can degrade code quality. For manufacturers relying on inkjet paper bag printing, reliable output hinges on more than just stable hardware; it demands continuous control over how, when, and where each code is applied.

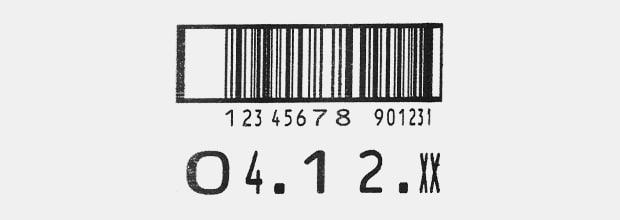

Stretched or compressed codes

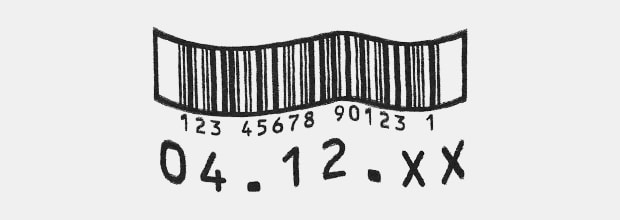

Wavy codes

We’re here to provide you with more details.

Reach out today!

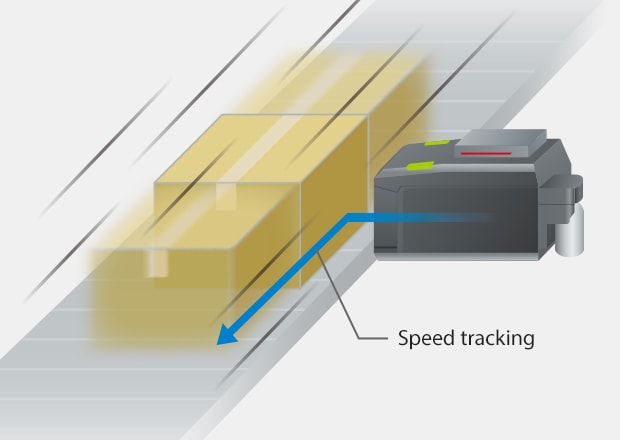

Adjusting Printhead for Variable Bag Speed

Speed variations caused by conveyor changes, gaps, or misfeeds make it difficult to maintain consistent code alignment. Systems that rely on static triggers or encoder timing can’t adapt mid-run, often producing stretched or compressed codes.

Manual adjustments become routine when coding on bagging lines. Each new product or speed setting can introduce fresh inconsistencies, especially if bag dimensions or spacing fluctuate between runs. These setup delays add cost and complexity for teams managing packaging machine coding across variable products.

MSU Speed Compensation for Bags

Zero print distortion

KEYENCE multi-sensing unit (MSU) enables precise print control by actively detecting speed, height, and bag movement during operation. The MSU adjusts print timing in real time, compensating for product variation and delivering distortion-free codes across all bag types.

MSU-equipped systems provide dependable inkjet coding for paper bags, reducing error rates without slowing throughput. No additional encoders or line modifications are required.

Curious about our pricing?

Click here to find out more.

Vibration Detection on Form-Fill Lines

Different types of conveyors, including roller conveyors, can cause vibrations, vertical movement, and misalignment, where the leading and trailing edges of the package may not be level, all of which disrupt print positioning.

The MSU eliminates these issues by detecting vertical movement or flutter before printing begins, preventing nozzle collisions, print misalignment, and the need for repeat runs.

Ink Selection for Porous Paper

Uncoated paper bags pull in ink differently than film or foil packaging. Without the proper ink formula, the ink can bleed into the fibers, causing barcodes to lose definition. To avoid this, many production teams use high-contrast inks developed specifically for porous substrates. Continuous inkjet and high-resolution printers support these ink types, maintaining code legibility even at higher speeds.

Integration with Bag Handling Systems

Paper bag packaging machines

Flat pouch conveyors and form-fill-seal machines don’t always deliver consistent bag height or orientation. For bagging lines that change formats or materials frequently, this kind of flexibility is essential to maintain print consistency without constant adjustment.

Systems built for integration, like inkjet printers for packaging machines with smart sensing and compact footprint, simplify setup and reduce the need for custom mounts or manual adjustment. Fewer changeovers, fewer failures, and more uptime.

Visit our product page to explore how the CC-1000 Series delivers reliable inkjet paper bag printing across demanding applications.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can Inkjet Codes Dry Fast Enough on Porous Bags?

Yes, fast-drying inks specifically designed for paper help to minimize smearing.

Does MSU Detect Bag Flutter Before Printing?

Yes, it automatically detects vibration and vertical motion, ensuring accurate print alignment.

What Traceability Standards Apply to Food-Grade Bags?

Commonly, GS1-compliant barcodes and date coding are required.

Can the MSU Work With Different Types of Conveyors?

Yes, it adjusts for height, speed, and motion in real time across various conveyor types.

How Can Inkjet Coding on Paper Bags Reduce Production Downtime?

Automated adjustments, diagnostics, and simple maintenance reduce errors and recovery time.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper