Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Date Code Printing on Flow Wrappers

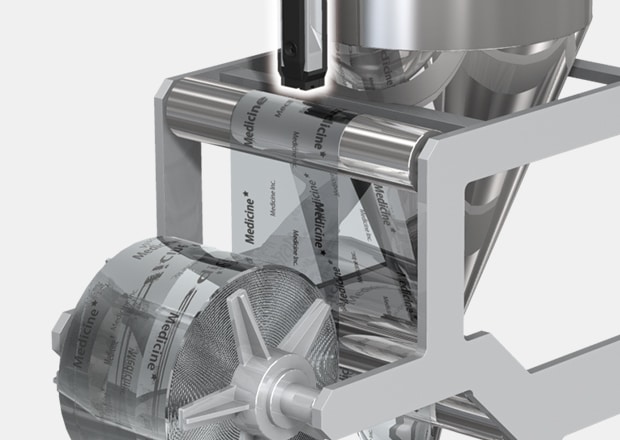

Flow wrappers also known as pillow type packaging machines can come in many different types, commonly used for packaging of food products, pharmaceuticals, paper products and many more in sealed flexible films.

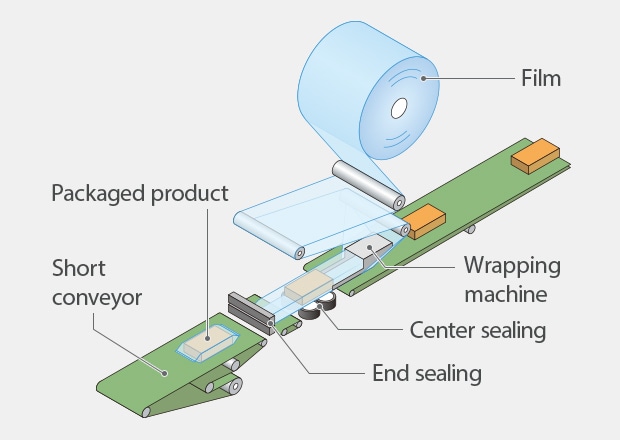

How Flow Wrappers Work

There are a few main variations of flow wrapping machines, but they all accomplish the same overall packaging steps using flexible films.

- Film Feeding: Continuous feeding of flexible packaging film from rolls.

- Forming: Shaping the film into a pouch or tube (vertical or horizontal).

- Product Filling: Accurate dosing and filling of the product into the formed film.

- Sealing: Heat sealing the film to create a sealed package (vertical and/or horizontal seals).

- Cutting: Separating individual packages by cutting the sealed film.

Horizontal form fill seal (HFFS) packing machine

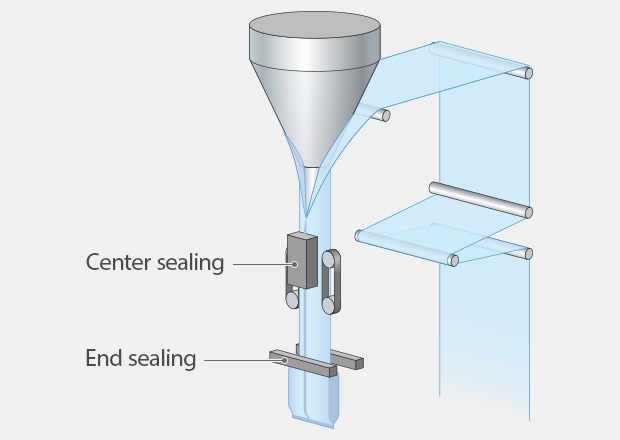

Vertical form fill seal (VFFS) packing machine

We’re here to provide you with more details.

Reach out today!

HFFS vs. VFFS: Understanding Horizontal and Vertical Flow Wrappers

The main differences are split into vertical and horizontal. They are often referred to as HFFS or horizontal form fill seal machines and VFFS vertical form fill seal. The names being a brief description of the machine’s main functions forming the pouch or package, filling it with product, then heat sealing it into individual packages.

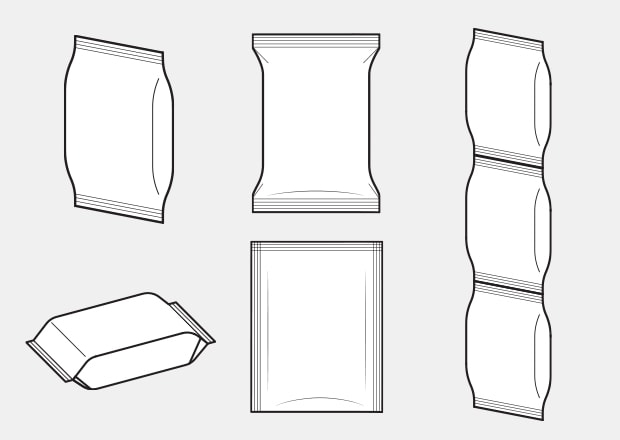

The traditional flow wrapper is often what is considered an HFFS. Horizontal flow wrappers are most used for structured items like trays of cookies, granola or protein bars, as well as paper products like wipes.

Packing sample

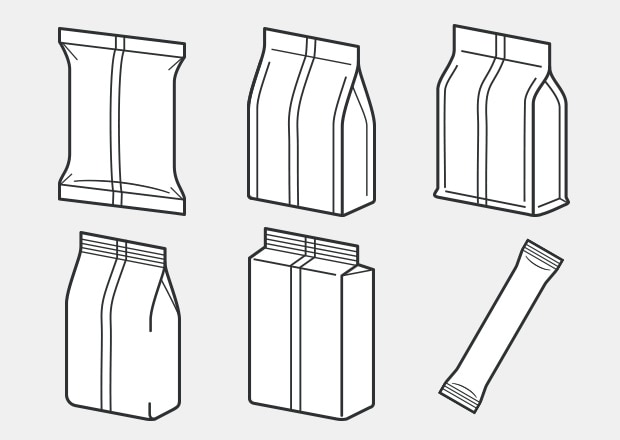

Packing type

The Vertical or VFFS packaging machines are used for granular or liquid packaging or things that do not maintain a uniform shape. More specifically, this would be a bag of mixed nuts, fruit snacks, protein/flavor powder tubes, and many more. A subset of vertical is known as sachet or stick pack machines, these are VFFS that do the same process across multiple rows at high volume.

Material

Packing type

Curious about our pricing?

Click here to find out more.

How MK‑G Series Minimizes Downtime and Maintenance Costs

The step missing in all these descriptions is of course, printing a date or lot code on the products. There is a wide range of film types, shapes, and sizes for these flow wrappers and they all require information to be printed on them for tracking and traceability purposes.

Installation example

Installation example

For ease of integration, little can be the MK-G Series CIJ able to be setup on most flow wrappers and printing in a matter of minutes. With flexible mounting in any orientation, high quality printing and adhesion, for continuous inkjet printing there is no better option on the market.

Cleaning at the push of a button, don’t waste time maintaining, cleaning, or replacing parts on the printing system, leaving plenty of time for production and for skilled maintenance staff to keep the flow wrapper running smoothly with perfect date codes printed on all product packages.

Pouches

Heat-sealed packages

Form-filled packages

Unprecedented IP rated print head, perfect for packaging environments, specifically the powdery and dusty environments mentioned for packaging powder supplements or snacks and nuts. Traditional printing options are IP rated, but this only applies to the controller which is safely hidden under the machine or in a cabinet. The print head must be right in the action, right next to the filler, where conventional printers will be clogged and damaged.

The nozzle is also susceptible to this dust and debris, so the MK-G Series is equipped with another industry first 1 touch replacement nozzle. Swapping the nozzle in under 1 minute is a cost-effective solution for getting production running again instead of the traditional downtime for flushing the nozzle or waiting for a maintenance tech.

No matter the exact machine type or product, the MK-G Series is a superior option for reliably printing lot and date codes on Flow wrappers or pillow packaging machines.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can CIJ Prints Adhere to the Various Plastic Films Commonly Used on Flow Wrappers?

Yes, the KEYENCE MK-G Series can adhere well to commonly used plastic polymers such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polyamide (PA). If adhesion is an issue due to dust, powders, or liquids on the film. KEYENCE also offers a brand-new type of technology for multilayer film in the FP-1000 Series UV laser coder. This UV laser marks below the laminate layer of the film and can mark through liquid and powder on the surface of films.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)