Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Case Coding on Box Conveyor Packaging Lines

Conveyor-based case coding introduces precision challenges not faced by static packaging setups. Speed changes, vibration, and box misalignment all impact print clarity. These issues put barcode accuracy, traceability, and compliance at risk, especially in high-throughput operations.

Common Conveyor Challenges in Case Coding

Conveyors, especially roller conveyors, can create vertical movement and vibration, causing the leading and trailing edges of a box to be at different levels. This misalignment can impact nozzle accuracy, resulting in head collisions, splashback, or clogging. Bump-turn systems attempt to correct orientation but require additional space and introduce points of failure. Inconsistent line speeds and mistimed sensors also lead to poor placement and distorted prints. On busy lines, that can mean unreadable barcodes, failed scans, and manual recoding.

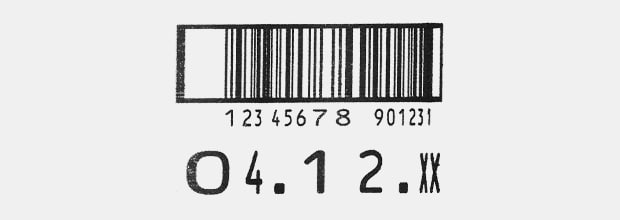

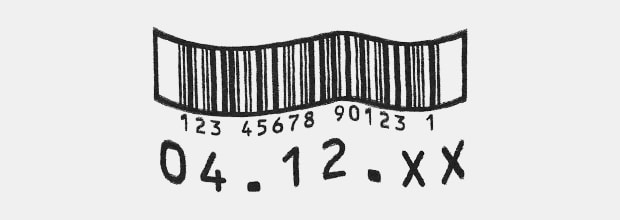

Stretched or compressed codes

Wavy codes

We’re here to provide you with more details.

Reach out today!

How the Multi-Sensing Unit (MSU) Solves Conveyor Printing Issues

The MSU, integrated into the KEYENCE CC-1000 Series, eliminates the challenges caused by uneven box levels, vertical movement, and vibration, ensuring consistent print alignment. The nozzle stays aligned even if the conveyor doesn’t. If conditions change beyond safe thresholds, the system alerts operators before problems occur. Paired with the built-in inspection camera, each print is instantly verified for position and content. This type of MSU conveyor stability ensures consistent print alignment on conveyors without requiring additional hardware.

Product shifting out of print range

Vibration detection

Head collision detection

Typical Packaging Process Applications

MSU-enabled case coders handle a wide range of industrial packaging conveyor printing setups, including shipping cases, retail cartons, flat-packed trays, and pouches. Lines that run varying product sizes or operate at variable speeds benefit most as the MSU adjusts without slowing production. Whether used in food, pharma, or general packaging, the MSU ensures stability across varying workflows.

Roller conveyors

Case sealers

Paper bag packaging machines

Benefits of Using MSU-Enabled Case Coding on Box Conveyors

Zero print distortion

The CC-1000 Series’ extended throw distance and 360 DPI resolution support clear, consistent printing on moving cases. The MSU automatically adjusts to speed changes and box position, preventing print misalignment and reducing wear on the system. It works without external encoders or complex triggers, utilizing integrated inspection tools that monitor each code in-line, identifying issues as they happen. For teams managing multiple SKUs, the MSU offers a scalable conveyor printing solution that maintains precision even with increased line complexity.

Eliminate the guesswork from conveyor printing solutions. Stabilize every code, avoid misalignment, and reduce rework with MSU-enabled case coding inkjet printers from KEYENCE.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What’s the Difference Between Roller and Belt Conveyors for Printing?

Roller conveyors can cause vibration and uneven motion, while belt conveyors provide smoother transport and better print alignment on conveyors.

Is MSU Compatible with Existing Packaging Lines?

Yes, MSU-equipped printers are designed to integrate into both new and existing conveyor systems with minimal adjustment.

What Types of Conveyors Can MSU-Equipped Case Coders Work With?

They work effectively on both roller and belt conveyors, including lines with variable product spacing.

How Does the Multi-Sensing Unit Improve Print Quality on Conveyors?

It automatically adjusts for speed, vibration, and position changes to maintain consistent print alignment on conveyors.

Can MSU Help Reduce Maintenance and Downtime?

Yes. By preventing print defects and reducing head collisions, the MSU helps extend system life and minimize rework.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper