Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Serial Number Printing on Extruded Plastics like Wire, Cable, and Piping

Building materials and electrical components are comprised of countless different extruded tubing materials from smalls wires to large pipes. All these examples often require a significant amount of serialized information printed along the length of the extrusion. In some cases, extremely high speeds are necessary to keep up with demands for hundreds of thousands of feet of electrical wire. In other applications for larger conduit or piping, the print required is much larger and more complex. These two requirements make printing on extrusion tubing, wire, and cable a challenge. Many technologies can only offer one of these features, high speed printing, or high-quality printing for coding plastic extrusions.

Continuous inkjet printers (CIJ) have the potential to meet both major needs but can traditionally have some drawbacks. The high-speed printing applications for wire and cable can often be limited by frequent maintenance and down time for traditional CIJ. While the higher quality logo and serialization printing requirements on piping are often hampered by similar issues to ensure no print defects. The drawback on this end is that clipped or poor-quality inkjet lot codes often result in significant scrap or rework. Whether it be downtime or scrap, even industrial CIJ printers are still eating away at the profits of extruded plastic manufacturers.

Enter the KEYENCE MK-G1000, a leap forward in continuous inkjet printing technology providing reliable and consistent high speed and high-quality prints across all types of extrusions.

We’re here to provide you with more details.

Reach out today!

Advantages for Increasing Throughput/Reducing Downtime

The Smart Dock, a built-in maintenance technician, performing PMs, and helping rapidly diagnose issues at the push of a button.

The nozzle is a traditional weak point of CIJ technology. Instead of flushing, KEYENCE’s patented ceramic nozzle can be replaced in under 1 minute for a fraction of the price.

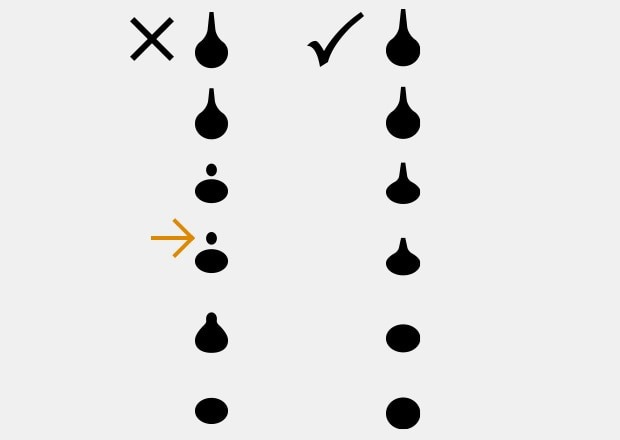

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

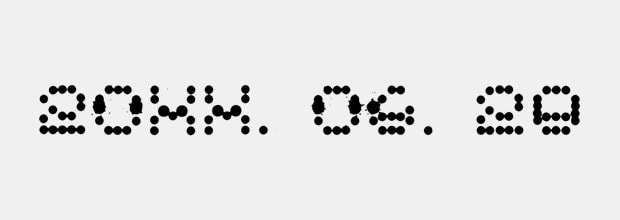

Break point monitoring ten times per second automatically ensuring dots are placed where they need to be. The result – less cleaning, less splatter so there is less downtime for maintenance and rework.

Less-than-optimal state of particles

Optimal particle state

Curious about our pricing?

Click here to find out more.

This Leads Us to Other Advantages for Print Quality on Extrusions

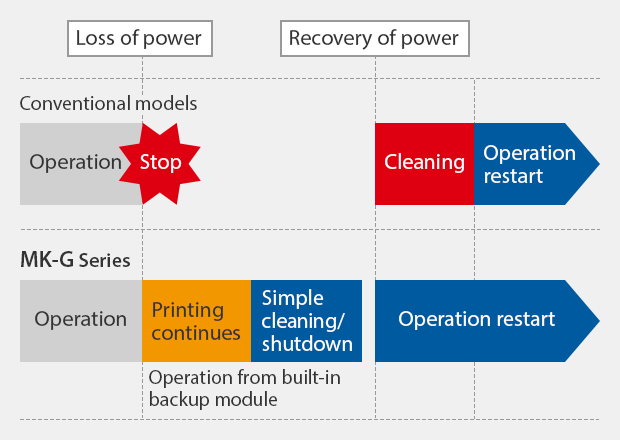

Built in backup power unit ensures the current print is completed even in the event of power loss. The printer will then perform an emergency shut down to be ready to go when the power is back.

No matter what the application, the MK-G Series is perfect for print on anything the extruded plastics industry can throw at it. Ready to run all day at high speed for wire and cable manufacturers that can’t afford a second of down time or piping and tubing manufacturers throwing away thousands on a single misprint.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can KEYENCE MK-G Series Printers Print All the Following Types of Content on Extruded Materials?

Serialized data, lot codes, date codes, logos, footage marks, cut marks, defect marks?

Yes, a logo converter, and easy to program interface allow the MK-G Series continuous inkjet printer to print small logos and an array of variable or serialized data updating automatically. It can also communicate with other devices like cutters to complete other process prints.

What Type of Materials Can Industrial Inkjet Printers Print On?

Continuous inkjet printers excel at printing on a wide array of materials. This is valuable in extrusions as many different polymers and plastics are used for things from polyurethane cable jackets and insulation all the way up to polyvinyl chloride (PVC) piping. These materials are often highly specific compositions, and KEYENCE is happy to provide test prints on these extrusions to find the best ink for each application.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper