Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Large Character Marking for Kraft Packaging

Kraft materials, while aesthetically appealing, aren’t easy to print on. Their rough texture, natural brown tone, and high absorbency make them unpredictable on the line. Ink bleeds. Barcodes blur. Marks fade or misalign. When kraft is used for food packaging, bulk industrial goods, or high-end retail, poor print quality turns into a production problem.

The CC-1000 Series from KEYENCE was built for exactly this kind of challenge. It delivers consistent results on porous substrates, adapts to shifting bags, and inspects every code as it’s printed. For manufacturers looking to keep lines running and codes clean, this system delivers the kind of coding and marking that kraft packaging demands.

Unique Challenges of Printing on Kraft Products

Kraft paper delivers strength, sustainability, and a natural visual appeal, but it’s far from simple to print on. Its fibrous, uncoated surface absorbs ink unevenly. That causes blurred edges, fading, and low-contrast marks, especially with traditional coders that lack the resolution or control to deal with porous substrates. This makes porous material printing a real obstacle on kraft packaging lines.

There’s also variability. Kraft packaging shifts during filling. They expand slightly when loaded or shift depending on how they’re handled. If the print system relies on fixed positioning or tight tolerances, those bags come out with misaligned or smeared marks. The challenge isn’t just the material, it’s the movement, the inconsistency, and the need to apply bold, legible codes on a surface that won’t cooperate.

This is where most systems fall short. They either print too close to the bag and risk ink splashback, or they lack the control to compensate for movement. In either case, the result is the same: inconsistent kraft product coding, unreadable barcodes, and traceability risks that ripple across the supply chain.

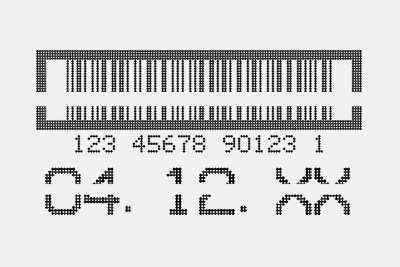

Missing lines

Blurred codes

Stretched or compressed codes

We’re here to provide you with more details.

Reach out today!

Why the KEYENCE CC-1000 Series Excels for Kraft Packaging

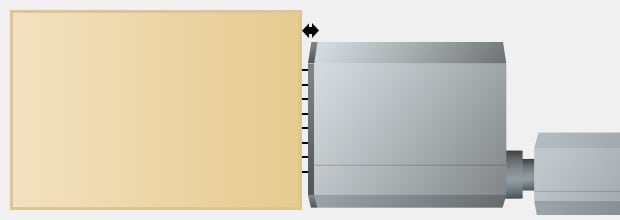

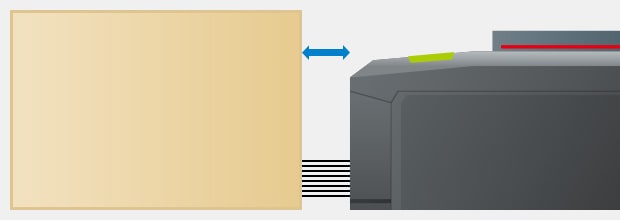

The CC-1000 Series doesn’t just work with kraft paper; it’s built for it. Unlike older coders that need to sit just millimeters from the surface, the CC-1000 Series is a case coding solution that can print cleanly from up to 0.6 inches away. That longer throw distance avoids smudging from ink splashback and protects the print head from accidental contact, even on bags with irregular shapes or shifting alignment.

Conventional models (short working distance)

CC-1000 Series (long working distance)

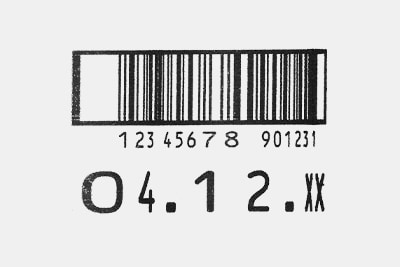

Zero print distortion

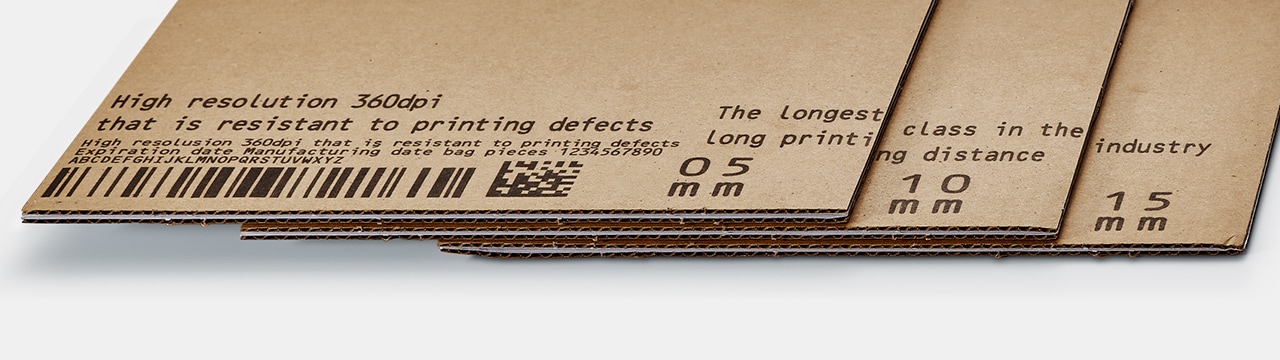

Its 360 DPI output is a cut above standard large-character coders. That matters for kraft, where the contrast between ink and substrate is already working against you. With the CC-1000 Series, codes stay sharp and legible, even barcodes and 2D matrix codes maintain definition across a full shift of printing.

A built-in sensor module automatically detects when a bag has shifted out of alignment or when the conveyor speed fluctuates. Instead of relying on fixed settings or operator judgment, the CC-1000 Series adapts to preserve print clarity.

The integrated print inspection camera closes the loop. It verifies the presence and quality of every mark right after it’s printed. That means no more worrying about unreadable bags making it out the door. If something goes wrong, the system flags it instantly, giving your team a chance to act before the product ships. From unbleached food bags to coated industrial sacks, the KEYENCE CC-1000 Series delivers kraft packaging printing that’s clean, aligned, and repeatable.

Curious about our pricing?

Click here to find out more.

Applications for Kraft Bag Printing

Paper product case coding spans more than one industry. Food manufacturers rely on kraft sacks for flour, sugar, beans, or coffee. Feed and seed operations pack bulk goods into reinforced kraft liners. Retailers and lifestyle brands use printed kraft bags to carry everything from skincare kits to apparel. And each application demands clarity, durability, and minimal rework.

Paper bag packaging machines

For manufacturers dealing with wide-format prints, batch codes, or brand logos, the CC-1000 Series handles it without interruption. Its rapid coding capability supports throughput rates compatible with high-volume packaging lines, minimizing bottlenecks and maximizing uptime.

Its high-DPI head and staggered nozzle design allow it to print large characters or compact 2D codes across rough kraft stock even when bags are recycled, coated, or slightly deformed from product weight. Because it compensates for movement in real time, operators spend less time adjusting for skewed placement or inconsistent height.

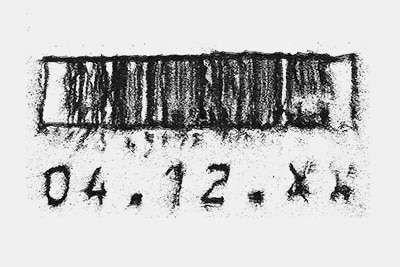

Printing example

KEYENCE Advantages for Kraft Packaging Solutions

Kraft printing demands more than clean output. It requires reliability across unpredictable conditions, and that’s where the CC-1000 Series stands out.

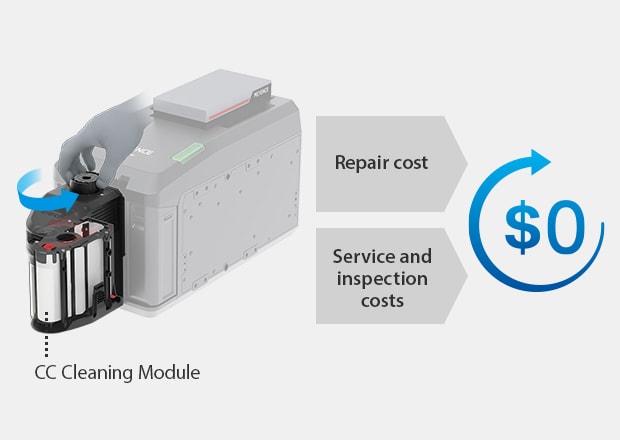

Maintenance is fast and clean. No more disassembling heads or catching dripping ink by hand. The CC-1000 Series’ cleaning module purges the nozzle without damaging it, and if the printhead core ever needs replacing, the swap is very simple and won't require the unit to come in for repair. There’s no need to remove the entire unit from the line.

Setup is just as simple. A centralized touch panel manages multiple units, so operators can control several kraft lines at once. That makes the CC-1000 Series especially effective in facilities running multiple product sizes or packaging formats. Users can scale without adding complexity, whether printing short-run kraft bags or managing high-throughput lines.

For teams focused on reducing waste and maintaining uptime, the CC-1000 Series’ inspection system adds a layer of control without slowing down. If a problem like low contrast, smearing, or vibration impact occurs, it’s logged and flagged before the product reaches QA. That keeps scrap low and compliance high, particularly for time-sensitive kraft packaging coding like expiration dates, barcodes, or serialized IDs.

For those building eco-aligned workflows, the CC-1000 Series fits the strategy. Its stable inks perform on porous kraft stock across a wide temperature range, helping teams maintain consistency without chemical-heavy coating or workaround materials. From unbleached food bags to coated industrial sacks, the CC-1000 Series delivers kraft packaging printing that’s clean, aligned, and repeatable.

Enhance Your Kraft Bag Coding Today with the CC-1000 Series

Whether you're printing on unbleached sacks, kraft packaging, or porous substrates, the CC-1000 Series delivers reliable results without manual effort.

Contact us today to see how the KEYENCE CC-1000 Series performs on your kraft bags.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper