Continuous Inkjet Printers / Case Coder

Materials and Products

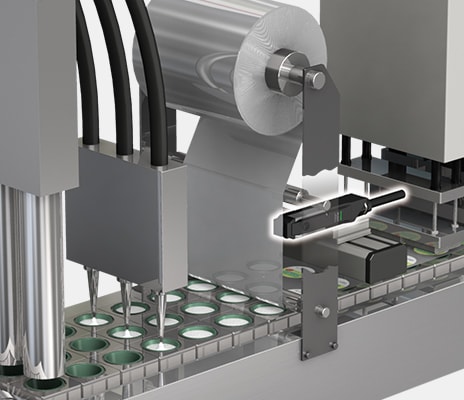

Production Machines

Printing Applications

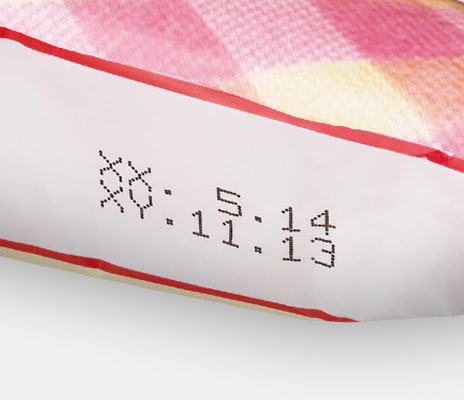

Date Code Printing on Pouches

A wide variety of flexible films and pouches are used to package goods across industries including food and beverages, pharmaceuticals, and personal care products. This widespread use is due to their versatility, sealing, cost, and convenience. Pouches are commonly filled or bagged via rotary bagging/filling machines or linear pouchers. Traceability, quality, and regulatory compliance via date and lot code printing is critical and most manufactures have settled on continuous inkjet printers (CIJ) as the industry standard for coding. Continuous inkjet printers (CIJ), like the flexible films and pouches they often print on, can print high quality and long-lasting lot codes and date codes on the many materials used.

We’re here to provide you with more details.

Reach out today!

Key Considerations for Choosing a CIJ Printer for Lot and Date Code Printing on Pouches

Manufacturers are looking for the following when deciding on the right CIJ to print lot and date codes on their pouches:

A simple to use coder, the MK-G Series walks users through maintenance and troubleshooting making anyone capable of cleaning and service. This is in part due to the Smart Dock, one push of a button and the smart dock does the thinking getting production up and running with ease.

Reliable and high-quality print. Break point is automatically monitored and adjusted 10 times per second to ensure perfect print and reduce interruptions for cleaning.

Rapid recovery from issues and errors preventing printing with one touch nozzle replacement. The nozzle is a common clogging point, so KEYENCE revolutionized the nozzle by making it cheap and easy to replace in under 1 minute. No more reliance on expensive parts and service contracts for traditional continuous inkjet printers (CIJ).

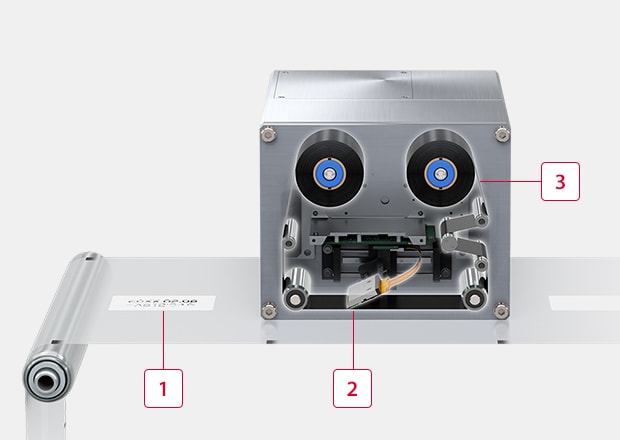

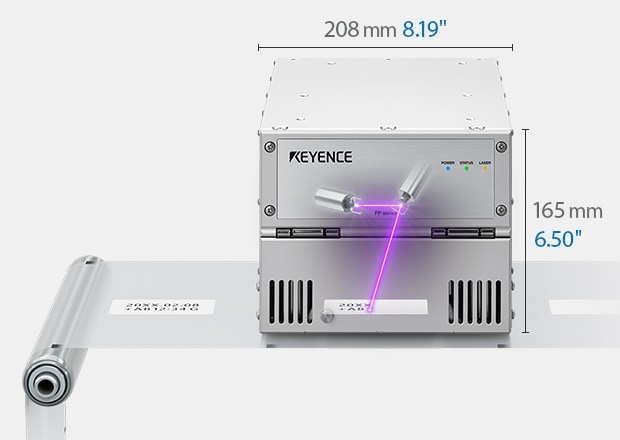

While the KEYENCE MK-G Series continuous inkjet printer (CIJ) has maximized the efficiency of inkjet coding on pouches, a new cutting-edge technology has been breaking into the industry: the FP-1000 Series UV laser coder. Find out more details on how this new technology is eliminating the maintenance, downtime, and consumables of traditional inkjet and ribbon printing on pouches and flexible films.

Conventional thermal printer

-

1Risk of marking that fades

-

2Thermal head replacement

-

3Ink ribbon replacement required

UV laser coders

Replacement of current TTO is simple due to similar outer dimensions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Is the MK-G Series Able to Print and Adhere Well on PP, PE, and PET Plastics Commonly Used in Flexible Films?

Yes, KEYENCE inks adhere well to plastics used in flexible film packaging. Super adhesive ink is also available for printing applications where the polymers and plastics are challenging to adhere to.

How Can KEYENCE CIJ Solutions Improve Production Efficiency and Reduce Downtime When Printing Date Codes on Pouches?

Diagnostics, troubleshooting, maintenance, and cleaning are all completed at the push of a button with the SMART Dock. Rapid recovery from clogs and dirty print heads reduces downtime and frees up maintenance staff availability for more critical tasks.

Does KEYENCE Offer Any Permanent Marking or Printing Solutions for Flexible Film Applications on Pouch or Bagger Lines?

Check out the most compact UV laser coder taking the industry by storm. Making maintenance and consumables obsolete, upgrade old Thermal ribbon printers (TTO) to the FP-1000 UV laser coder today!

Can Industrial Continuous Inkjet Printers Mark Lot and Date Codes on the Various Sizes and Shapes of Cans Used in Beverage and Other Industries?

Yes, the non-contact nature of CIJ printers makes them the perfect solution for inkjet printing lot and date codes on cans. The print head and settings are easily adjustable to accommodate different sized cans or print locations.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper