Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Serial Number Printing on Metal Parts

Easily apply clear, durable serial numbers and lot codes to metal parts—even those with coatings, curves, or challenging surfaces—using KEYENCE’s advanced continuous inkjet (CIJ) printers. Discover how our technology delivers high-contrast, reliable marks without slowing your production or compromising part quality.

Why Choose KEYENCE CIJ Printers for Lot Code Printing

Metal surfaces are often painted, coated, curved, or exposed to heat and vibration, none of which makes it easier to apply a clean, lasting code. Lot code printing depends on contrast, placement, and adhesion, and it has to happen without slowing the line or compromising the surface.

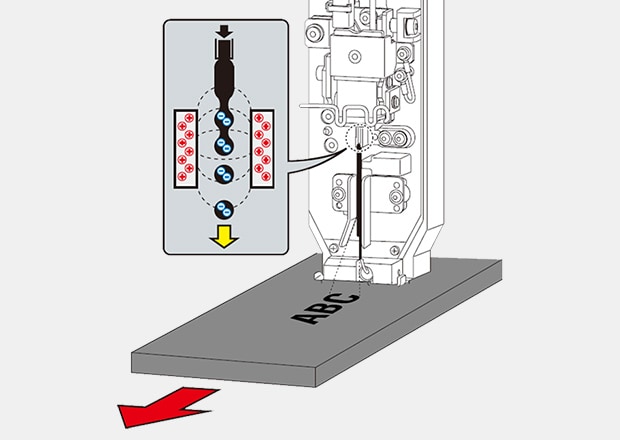

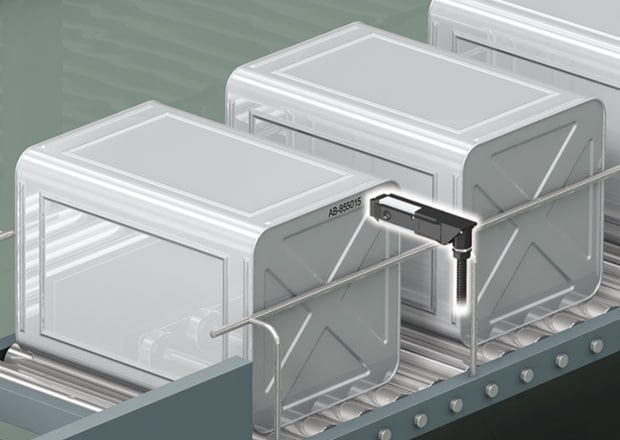

A continuous inkjet (CIJ) printer handles that challenge with precision. Continuous inkjet technology applies marks without contact. There’s no need to press against the part or prep the surface in advance. The ink is applied where it’s needed, even on irregular or moving components. For fast-paced environments that demand readable, durable codes, that kind of adaptability matters.

We’re here to provide you with more details.

Reach out today!

Benefits of CIJ Technology for Lot Code Printing

CIJ systems operate by firing small, charged ink droplets toward the target surface. Because there’s no physical contact, the method works well on non-porous materials like metal. Even delicate finishes remain untouched. Pigment-based inks, particularly white and yellow, stand out sharply on dark surfaces and resist fading, smearing, or transfer.

CIJ also supports continuous output. With fast-drying formulas and minimal intervention required between runs, the system works across long shifts without constant oversight. For applications like lot code printing on metal, automated cleaning cycles, real-time ink management, and efficient solvent use help maintain print quality without added effort.

Applications for Metal Parts

CIJ printing is used to apply lot codes, batch numbers, and serial data to a wide range of metal parts, including:

- Coated panels and housings

- Brackets and mounting plates

- Pipes, tubing, and flanges

- Faceplates, fasteners, and enclosures

Curious about our pricing?

Click here to find out more.

Key Features of the MK-G Series CIJ Printers

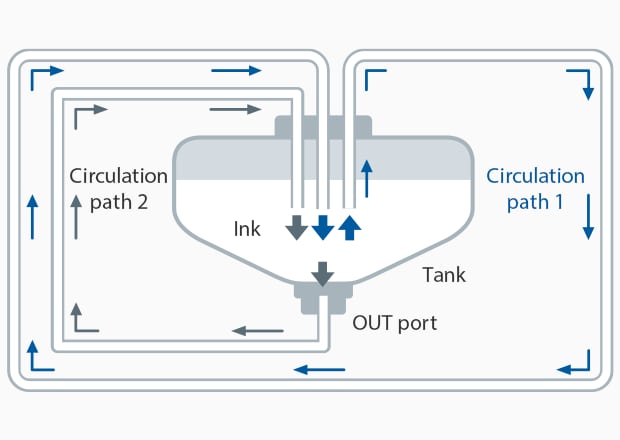

The MK-G Series takes CIJ performance further with its automated ink particle sensing, which adjusts flow and viscosity up to ten times per second, maintaining consistent print quality across shifts and environments. The dual-circulation system keeps pigment inks like white and yellow stable without frequent cleaning.

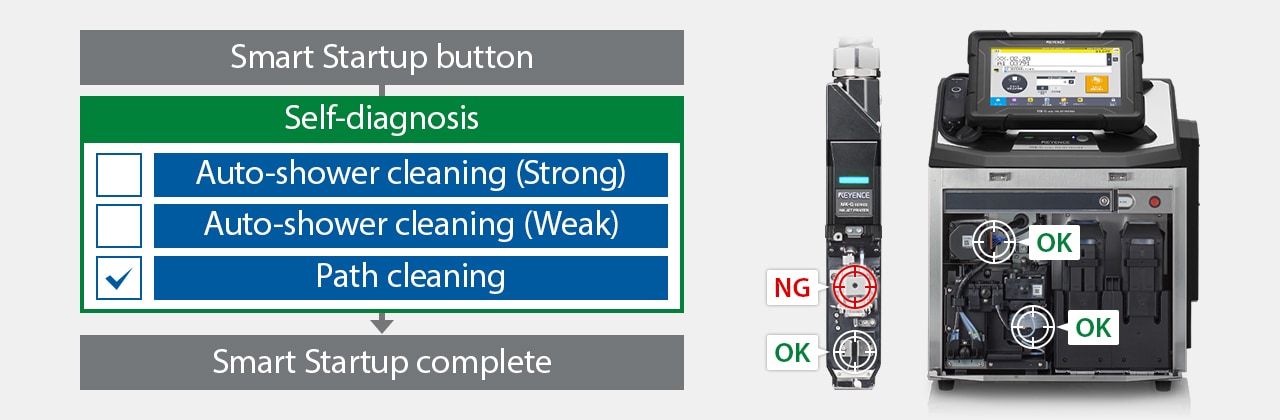

Smart Startup and Shutdown routines reduce solvent waste and eliminate unnecessary maintenance steps. The printhead can self-diagnose when docked, triggering cleaning only when required. Remote access tools let teams monitor status and make adjustments without being on the floor. For operators, the system is easy to manage, with simple nozzle replacement and visual guidance for troubleshooting.

With an IP55 rating and a design that meets MIL-STD drop compliance, the MK-G Series holds up in environments where other printers might not. It’s a durable metal CIJ printer built for uptime.

The MK-G Series is rated IP55, making it both waterproof and dustproof.

Both the head and the console comply with MIL Standard drop evaluation requirements.

Inkjet Printing Compared to Laser Printing for Metal Parts

Laser systems have their place, but coated metal isn’t always one of them. Lasers often require surface prep or exact conditions to produce a reliable mark. They can struggle with curved geometry or dark, non-reflective coatings. CIJ handles those variables without hesitation.

It delivers high-contrast codes without abrasion, heat, or post-process cleanup. For manufacturers using continuous inkjet for automotive parts, this means high-speed, high-contrast marking without interrupting downstream processes. In applications where changeovers are frequent and substrates vary, CIJ provides the flexibility needed to keep production moving.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can You Print Directly onto Coated or Painted Metal Surfaces?

Yes. CIJ printers apply ink without contact, so they print cleanly on coated, painted, or finished metals without damaging the surface or requiring prep.

What Makes the MK-G Series CIJ Printers Ideal for Metal Parts?

The MK-G Series adapts in real time to environmental changes and ink viscosity, supports high-contrast pigment inks, and features automated cleaning, making it perfect for high-speed, variable metal marking.

What Are the Pigmented Ink Color Options When Printing on Metal Parts?

The MK-G Series supports white, yellow, and other pigment-based inks designed for high contrast on dark or reflective metal surfaces, ensuring readability and durability.

Will CIJ Printing Affect the Corrosion Protection Provided by Coating on Metal Parts?

No. CIJ printing is non-contact and uses fast-drying inks that don’t compromise protective coatings or finishes, preserving corrosion resistance.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper