Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Date Printing on Bottle Filling Machines

Bottle fillers are used in a wide range of industries. Anything that requires liquid products will use some type of automated bottle filling system. The beverage industry would be the first to come to mind, requiring many variations of bottle fillers for each type and size of consumer drink from water, juice, soda, beer, and of course dairy products, notably milk. Other commonly found bottled products include industrial chemicals like household cleaning products and detergents as well as automotive oil, coolant, etc, and then furthermore agricultural chemicals and fertilizers. One last sector that used bottle fillers for frequently used products would be personal care and cosmetics products like soaps, shampoos, lotions, and hand sanitizer.

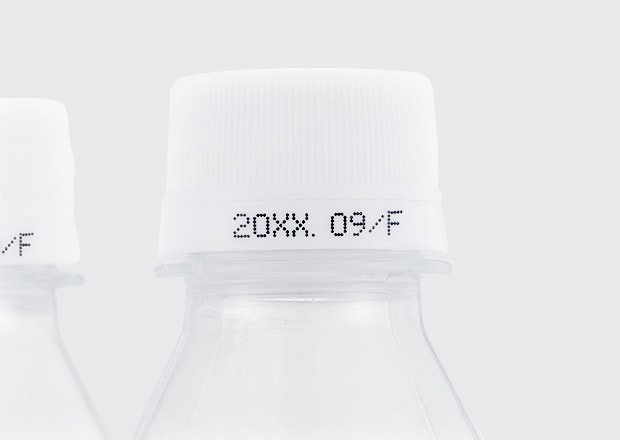

Printing example

Installation example

We’re here to provide you with more details.

Reach out today!

Why Reliable Date and Lot Coding Is Critical for Every Bottle Filling Line

The range of industries and then the countless liquid products encountered daily are limitless and that is why bottle filling systems are so critical. For all these products, a reliable method of printing for tracking and traceability is critical. For bottled food and beverages, an expiration date is both FDA required and critical for customer freshness and satisfaction. Printing date codes on bottles is a critical step in the filling process and a high speed and reliable printer is needed to meet regulations and ensure customer satisfaction, not to mention cost savings and efficiency.

KEYENCE’s MK-G Series Continuous Inkjet Print (CIJ) is perfect for all the challenges and variations of printing date and lot codes on bottles.

With unparalleled speed while maintaining high quality print, few can deliver date code prints on bottles as reliably.

PET bottles

Cosmetics containers

How the MK‑G Series Conditioning Tank and Sensor Monitoring Deliver Reliable 24/7 Bottle Coding

An additional tank to buffer ink viscosity works in tandem with a specialized KEYENCE sensor in the print head to ensure perfect prints 24/7 even in the wet and changing climates bottle fillers are used in. The extra tank called the conditioning tank collects solvent used for cleaning and maintenance, this stabilizes viscosity as in conventional CIJ it is just dumped back into the main tank.

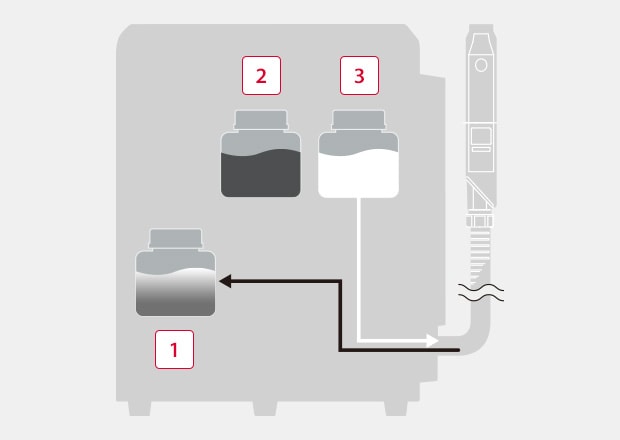

Conventional

When washing is performed, the ink viscosity decreases.

-

1Main tank

-

2Ink tank

-

3Solvent tank

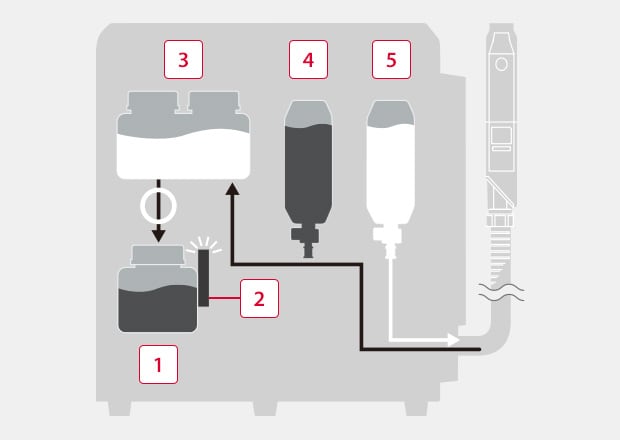

MK-G Series

The conditioning tank is used for temporary storage to prevent dilution of the ink.

-

1Main tank

-

2Viscosity sensor

-

3Conditioning tank

-

4Ink cartridge

-

5Solvent cartridge

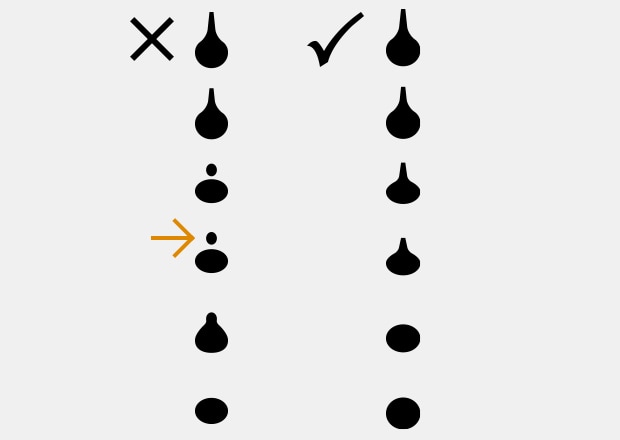

Particle state:

If the optimum ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Then in real time, KEYENECE, being a sensor company, monitors dot breakpoint ten times per second to ensure perfect print on each bottle.

Less-than-optimal state of particles

Optimal particle state

Another benefit unique to the MK-G Series is that the print head itself is IP rated to survive the overflow, spills, spray, and general moisture that comes with large volumes of fluids being added to the bottles. An exploding soda or overfilled bottle can cause significant downtime on traditional CIJ print heads, but only the MK-G Series is truly equipped to handle the difficult task of printing date codes on bottle filling machines.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What Types and Sizes of Bottles Can Continuous Inkjet Printers Print On?

CIJ are flexible printers, the MK-G Series is capable of mounting and printing on bottles in any orientation. The print head just needs to be mounted about ½” from the bottle and it can mark anywhere, the bottom, side, shoulder, and even on the cap. A special head shape also helps avoid obstruction on abnormal bottle shapes and the head can be updated to a 90-degree orientation to print in tighter bottle fillers.

Can Industrial Inkjet Printers Print on Glass and Bottles as They Are Filled?

Yes, glass and various plastic bottles can be printed on with high adhesion even in the various environments and moisture commonly found in bottling manufacturers.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper

![Process-specific Marking Applications [Food/Pharmaceutical Industry]](/img/asset/AS_133442_L.jpg)