Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Continuous Inkjet Printer Info

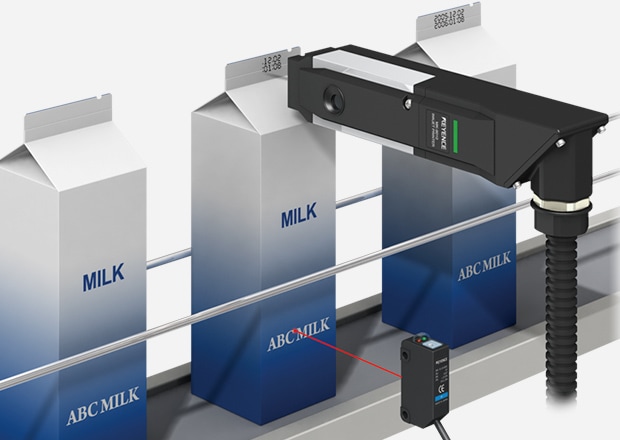

Continuous inkjet printers, just like typical consumer-grade inkjet printers, transfer ink onto the substrate to produce legible text. However, unlike consumer-grade inkjets, continuous inkjet printers are industrial equipment most commonly used for printing important code information on various goods and products.

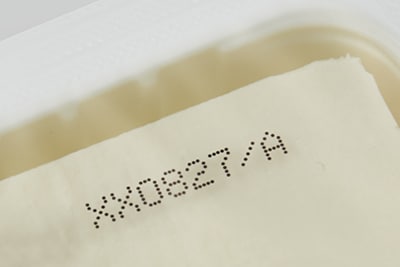

Great examples of this would be the lot codes or date stamps on perishable items you would find at the grocery store such as a jug of milk.

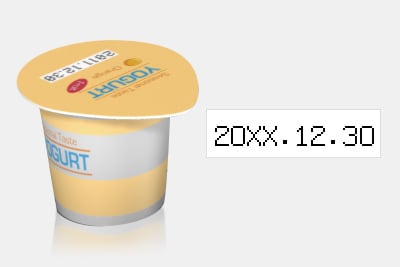

Yogurt

Ice cream

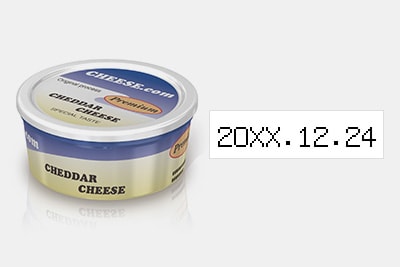

Cheese (cup container)

Difference Between Traditional Printers vs. Continuous Inkjet Printers

Basic Knowledge

These printers do not need the same mechanical devices required in copiers and laser printers, which use offset printing and heat fusing. The ink particles in inkjet printers are discharged using a non-contact method, so the target does not need to be completely flat as it does for printing presses.

Also, continuous inkjet printers rely on continuous ink flow to produce prints, which also reduces costs associated with maintenance, as the flowing ink doesn’t clog up the print head. Additionally, they’re incredibly fast, and more advanced models can print up to 470 m of single-line text per minute.

Types and Methods

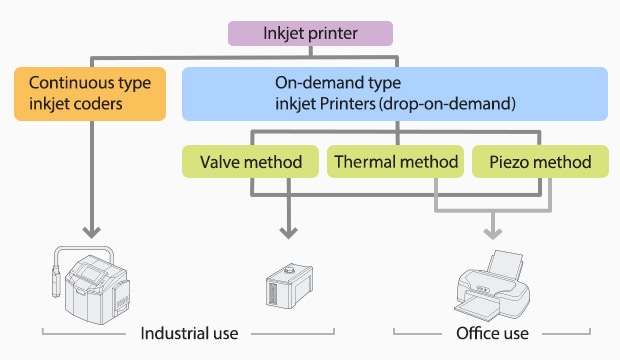

Inkjet printers are broadly categorized into two types: continuous and on-demand. On-demand types are further separated into piezoelectric, thermal, and valve types.

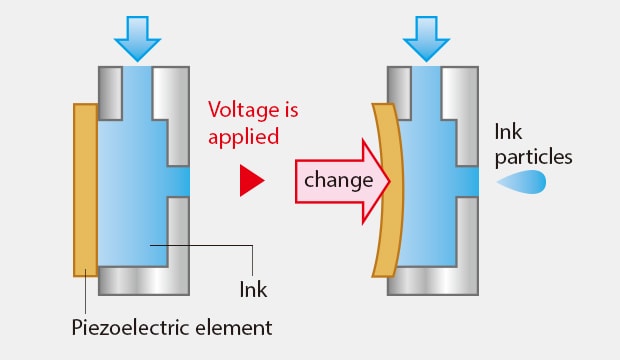

Piezoelectric Type (Office/Industrial)

This type discharges ink particles using a piezoelectric element that changes its volume when voltage is applied. This element is attached to the unit that has been filled with ink. The change in volume is used to apply pressure causing the ink particles to be discharged from the nozzle.

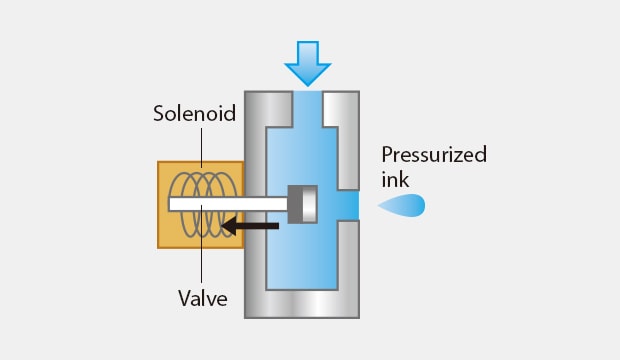

Valve Type (Industrial)

This type discharges ink particles by opening and closing the cover of the nozzle hole with a solenoid. The valve is opened and closed to discharge pressurized ink from the nozzle.

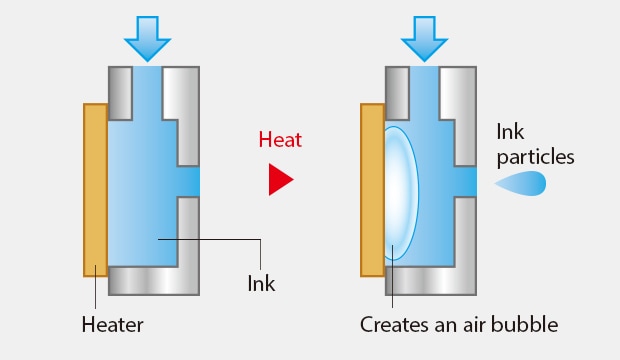

Thermal (Valve) Type (Office/Industrial)

This type discharges ink particles by creating an air bubble in an ink-filled unit with the heat from an attached heater.

Office and Industrial Use

Inkjet printers are grouped into office printers, which are typically connected to a computer in a home or an office, and industrial printers, which are used on production lines in factories.

Office inkjet printers

These printers are used in a wide range of applications, such as printing pictures, work documents, and large posters. On-demand is the most commonly used type of printer in offices, particularly the piezo and thermal method printers.

Industrial inkjet printers

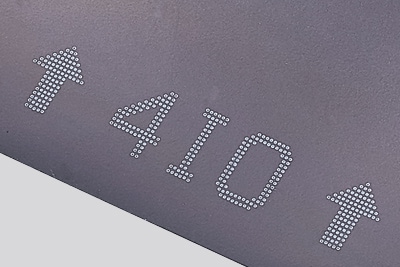

Industrial inkjet printers can print not only on paper but on many types of materials, such as packaging films, cans, and plastic bottles. To print on products moving on production lines, ink is designed to be quick-drying.

These printers are primarily continuous-type, while on-demand type printers are used specifically for printing large characters on cardboard boxes and similar objects.

Industrial Inkjet Printer Advantages

Able to print on a variety of materials

These printers can print on many types of materials, including paper, plastics, and metals.

Cardboard boxes

Plastic bottles

Cans

Capable of high-speed printing with quick-drying ink

With a drying time of around one second, prints adhere to surfaces quickly and are not easily removed.

Glass containers

Packaging film

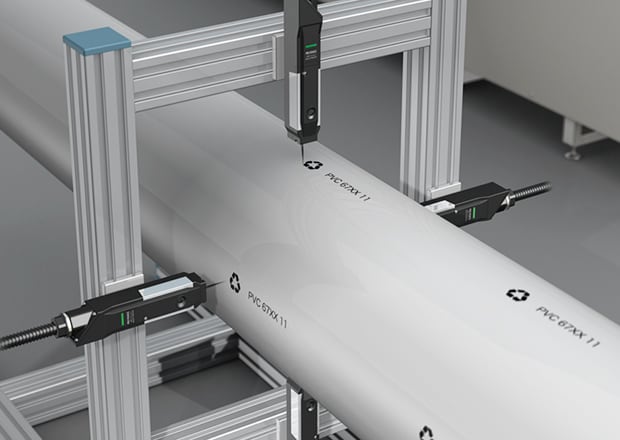

Pipes

Capable of printing without moving print head back and forth

The printer can work in several configurations. It is designed to stay fixed on production lines of any speed or move in traversing head applications.

Cartons

Heat-sealed packages

Bottle labels

We’re here to provide you with more details.

Reach out today!

Applications of Inkjet Printers in the Packaging Industry

There are many applications of inkjet printers in the packaging industry, which relies heavily on CIJ printers to print out the necessary information on glass and plastic packaging with great precision and speed. This refers to the information that’s important to both the manufacturer and the consumer of goods.

For example, the expiration date of the product, regardless of what that product might be, is an essential piece of information. Products past this date should be removed from sales, shouldn’t be used, and should be disposed of correctly, as they’re either unsafe for use or have lost their effectiveness.

Lot numbers and batch codes are also important for manufacturers. These numbers denote products that are made as part of a single batch, which implies the production under the same manufacturing condition. This is useful for quality control and logistics, especially when product and goods recalls are issued.

Lastly, serial numbers serve a variety of purposes. These numbers are unique to each product and allow for easier tracking during all stages of production, distribution, and sales. Additionally, they’re crucial when it comes to warranty and service claims, theft prevention and recovery, and inventory management.

Form-filled packages

Film

Paper tubes

Discover more about this product.

Click here to book your demo.

FAQs About Continuous Inkjet Printer Info and Printing in the Packaging Industry

What Is an Industrial Continuous Inkjet (CIJ) Printer, and How Does It Differ From Other Inkjet Printers?

Continuous inkjet printers are industrial-grade printers used for code and label printing across numerous industries. As their name implies, they eject ink from the print head, but that’s where any similarities with other inkjet printers end.

Continuous inkjet printers rely on the continuous flow of ink, whereas traditional inkjet printers only expel ink when needed to create an image. The latter don’t have a continuous stream of electrostatically charged ink and usually aren’t nearly as fast as CIJ printers.

Additionally, CIJ printers are highly efficient at high-speed printing, which is ideal for industrial applications, but they also incur high maintenance costs due to their complex mechanism and the nature of fast-drying ink—which is why the ink has to flow continuously, to prevent drying and clogging the print head.

Lastly, CIJ printers are more expensive, both in terms of initial costs and operating expenses, which reflects their industrial application.

Are There Specific Maintenance Requirements for Continuous Inkjet Printers?

Similar to any other industrial machine, CIJ printers necessitate regular maintenance and cleaning for optimal operation, often requiring daily print head cleanings to ensure clear print and to maintain functionality. Adjustments to viscosity, break point, drains, and many other troubleshooting and maintenance procedures can occur frequently. The more variable and difficult the environment is, such as temperature swings, humidity, or dust can result in more frequent issues and cleanings. There is also periodic replacement of consumable parts such as filters and pumps.

Regular maintenance is crucial to ensure optimal performance and print quality of printers. By preventing the accumulation of dust, ink residue, and other contaminants, you can safeguard the printer's functionality.

Ready to take your industrial printing to the next level? Consider investing in a KEYENCE CIJ printer. Contact us now to learn more about our CIJ printers and how they can improve your print quality.

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

![Inkjet Printer Tech Guide [BASIC KNOWLEDGE EDITION]](/img/asset/AS_114378_L.jpg)

Continuous inkjet (CIJ) printers work by discharging ink particles to print information such as characters and figures on targets. This document describes the differences between industrial use inkjet printers and office-use printers, as well as their structures, circulation principles, and application examples.

This is a technical guide describing basic knowledge of continuous inkjet (CIJ) printers from mechanisms such as the types, printing fundamentals, and internal structure, to running costs and legal compliance. Subsequent issues will also be available. By reading all of these issues, you can understand the entire overview of continuous inkjet (CIJ) printers.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper