Continuous Inkjet Printers / Case Coder

Materials and Products

Production Machines

Printing Applications

Purpose of Printing Best-Before Dates and Lot Numbers

Products are printed for various reasons. For example, printing is required to comply with legal requirements, to manage in-house products and inventories at a manufacturing plant, or to identify products on logistic routes.

KEYENCE ultra-high-speed and non-contact industrial inkjet printers can be easily installed on existing packaging machines.

Through built-in sensors and optimization, flawless and clear marking of expiration dates can be achieved.

Curious about our pricing?

Click here to find out more.

Printing Best-Before Dates on Food Products

Best-before (use-by) dates help consumers determine the freshness, make informed purchasing decisions, and safely use perishable products. By having this information readily available on products, the producers clearly state the period in which a product should be used as well as limit their liability.

Space restrictions may prevent printing the best-before date on products, in which case the best-before date can be printed separately upon indicating where the consumer can find the printing. Food labeling has many rules. For example, producers need to be cautious when printing both the lot number and factory identification code.

We’re here to provide you with more details.

Reach out today!

Printing Lot Numbers and Serial Numbers

To maintain and control stable quality, products are printed with codes that indicate when and where they were made. When a serious complaint occurs and a product recall is needed, the production lot can be identified with these codes. This allows manufacturers to pinpoint the cause of the error and limit the magnitude of the recall as part of the defensive measures.

Discover more about this product.

Click here to book your demo.

Printing Codes for Process Management

Identification codes and barcodes can be printed on parts to indicate necessary information to aid in the manufacturing process. This helps improve production efficiency and quality control. Some examples that are used are printing pass/fail indicators on parts so that defective parts are not used in final products and printing readout values on parts for any adjustment required further down the line.

Curious about our pricing?

Click here to find out more.

Printing for the Prevention of Counterfeit Products

Secret numbers and codes are printed on products recognized only by the manufacturer. If counterfeit products should appear, the manufacturer can use these codes to distinguish which products are unlawful imitations. This printing application has been used as a means of protecting proprietary brands.

We’re here to provide you with more details.

Reach out today!

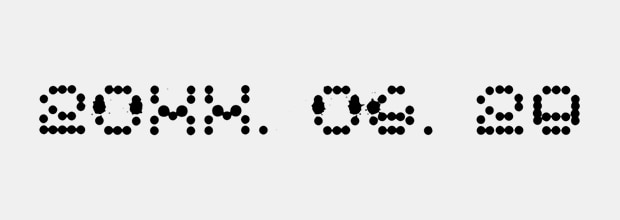

Best Lot and Date Codes Printing Practices

Printing best-before dates and lot codes are among the most crucial practices for quality control, traceability, and compliance with stringent regulatory standards governing various industries dealing in the production and packaging of perishable and other types of goods.

One of the best practices when it comes to printing best-before dates is to ensure the high legibility and durability of the print. However, these aren’t the only practices; these codes also have to be clear, printed in a readable font, and in a size that’s easily visible yet proportionate to the packaging.

It’s also essential to consider the color of the ink, as it has to stand out against the color of the packaging, or in the case of transparent packaging, such as clear glass and plastic, against the contents within.

Another key aspect is selecting the right printing technology. Continuous inkjet printers are the most commonly used printers in these applications due to their versatility and efficiency. They can print on many different substrates regardless of their shape and size , due to quick drying and strong adhesion ink. This is where ink selection also plays a crucial role; inkjet printers can print on a variety of materials as long as they use adequate ink.

These factors are essential for diverse packaging needs. Laser markers are also used in applications where durability is a concern because their marks are permanent and are more resistant to fading and abrasion , but they can’t match inkjet printers in terms of substrate versatility.

The placement of the codes when printing best-before dates and lot numbers is also important, as the print needs to be applied to an easily accessible and visible location on the packaging. Consistency is key, as it aids quick identification and scanning, which is particularly important in various applications.

Usable Anywhere

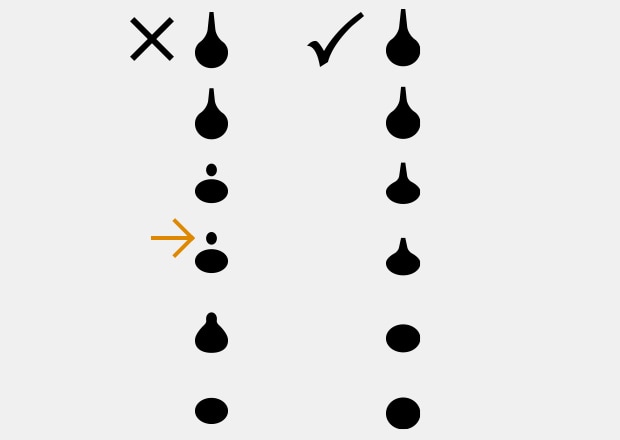

Particle state

Consistent printing under various environments

The ink particles are optimized for the state of the ink.

There is no need for adjustment by the operator. If the optimal ink state is not maintained, the inside of the head may become dirty, and print quality may deteriorate.

Non-optimal particles

Optimal particles

| Season | Temperature | Humidity |

|---|---|---|

|

Summer

|

Temperature

30°C 86°F

|

Humidity

70%

|

|

Fall

|

Temperature

23°C 73.4°F

|

Humidity

35%

|

Resistant to seasonal changes

That’s why people choose the MK-G Series!

Even when the ambient temperature or humidity changes with the seasons, the state of the ink particles is always optimal.

Get detailed information on our products by downloading our catalog.

View Catalog

Printing Lot and Date Codes to Help with Tracking and Traceability in the Manufacturing Process

Besides complying with stringent regulations regarding perishable goods, printing lot numbers, as well as printing best-before dates, is also crucial for tracking and traceability during the manufacturing process and subsequent storage and transport.

These codes are an important link in the chain of quality control, as they ensure that each product can be traced back to its production batches by simply referring to its lot and production codes. This practice is rather important for manufacturers, but also consumers, as it provides a clear trail from the initial production to the end user. As you might’ve guessed, these numbers are also mandated by regulations.

When it comes to best practices associated with the printing process alone, the same practices described above apply here as well. However, printing serial numbers are typically used for product traceability; they should be placed strategically to ensure easier scanning during storage and transport.

KEYENCE can provide a comprehensive coding and print inspection solution to enhance tracking and traceability during the manufacturing process. Our systems can verify the presence or absence of these date codes, ensuring that no unacceptable products are released due to missing information. This eliminates the need for multiple vendors, as KEYENCE offers a single vendor integration between multiple products.

Visit our website to learn more about continuous inkjet printers today!

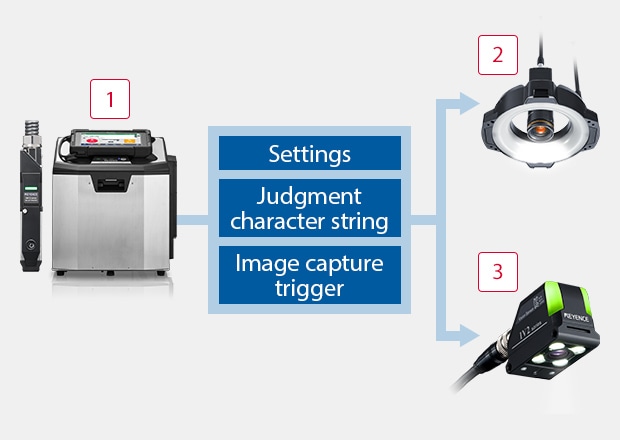

Direct Connection to Print Inspection Equipment

Easily link to a print inspection device with just a LAN cable.

The MK-G Series can be easily linked to a print inspection device by connecting a LAN cable.

Easily transfer settings, judgment character strings, image capture triggers, and more. Print inspection devices ensure products are not released if printed details are missing or incorrect, providing an extra layer of reliability.

-

1Continuous Inkjet Printer - MK-G Series

-

2Intuitive Vision System - CV-X Series

-

3Vision Sensor with Built-in AI - IV3/IV2 Series

Get detailed information on our products by downloading our catalog.

View Catalog

Related Downloads

This guide explains continuous inkjet (CIJ) printer applications together with pictures and illustrations. It contains many installation examples in various industries divided into food, medicine, and cosmetics; electrical machinery and electronics; and automotive, metal, and others. These examples show printing on targets specific to each industry.

Related Products

Applications

Materials and Products

- Glass Bottles

- Plastic Bottles/Containers

- Cans

- Wires, Cables, & Pipes

- Pouches

- Metal Parts

- Corrugate Boxes

- Packaging Film

- Kraft Packaging

- Folding Cartons

- Building Materials

- PCBs

- Cartons

- Pallets & Lumber

- Corrugate Trays

Production Machines

- Paper Bag Packaging

- Box Conveyor

- Automatic Palletizer

- Sealer/Taping Machine

- Bottle Filling Machine

- Flow Wrapper