Data Acquisition (DAQ)

How to Measure Shock & Vibration with Accelerometers

-

Tags:

- Acceleration , Aerospace , Automotive

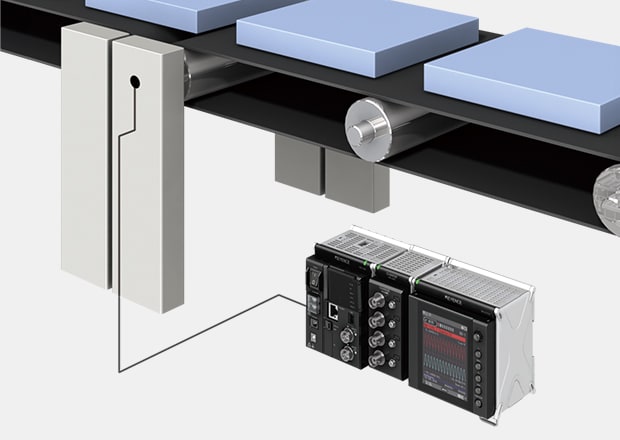

Unnoticed forces, like shock or vibration, can disrupt production lines and manufacturing processes without warning. These seemingly minor movements can lead to mechanical wear and tear and unexpected failures.

Accelerometer sensors are designed to catch and measure small changes in movement; they offer insights that allow engineers to monitor and address issues before, for example, a loose bolt becomes a broken conveyor belt.

Understanding Accelerometer Sensors: What They Measure

Accelerometers, true to their name, take acceleration measurements, or, the velocity change rate over time. They detect vibrations, shocks, and tilts in equipment by sensing the motion of a small, damped mass (also known as a proof mass) inside the sensor. This mass moves in response to external forces.

When it moves, the accelerometer generates an electrical signal that is proportional to the amount of movement. That electrical signal is then analyzed to assess the magnitude of the shock or vibration. Vibrations happen at many different frequencies, so it is important to capture low-frequency vibrations, such as those in rotating machinery, and high-frequency shocks, like those in automotive testing.

Accelerometers complete these measurements using an equation: units of meters per second squared (m/s²) or g-force (g), where 1g is the force of gravity.

We’re here to provide you with more details.

Reach out today!

Types of Accelerometers for Shock & Vibration Measurement

There are several types of accelerometers, each with its strengths, and the intended application determines which sensors are put into use. However, there are a few sensors that are more commonly used than others, including:

- Piezoelectric Accelerometers: These sensors use the piezoelectric effect, or the use of certain materials, like quartz, to generate an electrical charge as a response to mechanical stress. They are ideal for high-frequency vibration measurements and are prevalent in automotive and aerospace manufacturing. This type of accelerometer is commonly used with the NR-Series data logger. Our acceleration input card, the NR-CA04, can accept Piezoelectric or change type accelerometers via BNC connection or Miniature (10-32UNF) connector.

- Piezoresistive Accelerometers: In contrast to the piezoelectric effect, piezoresistive sensors measure changes in electrical resistance as a result of mechanical strain; they are well-suited for low-frequency measurements and offer greater sensitivity.

- MEMS Accelerometers: Micro-Electro-Mechanical Systems (MEMS) accelerometers are small, low-power devices used in consumer electronics and wearable technology. These sensors measure vibrations over a broad frequency range.

- Capacitive Accelerometers: These sensors measure changes in capacitance, the amount of charge that can be stored at a given voltage, as a result of acceleration.

How Accelerometers are Interfaced with DAQ Systems

Accelerometers are connected to a high-speed data acquisition (DAQ) system to analyze data. These DAQ systems, like the NR-Series, collect, store, and process the accelerometer data through a specific data protocol. DAQ systems are also not only limited to servicing one sensor as they can handle multiple accelerometers at one time, which allows for a more thorough monitoring regardless of sensors being located across various locations on machinery or different parts of infrastructure.

On top of multiple accelerometer sensors, DAQ systems can also track and monitor data from other sensors, such as those that measure temperature and pressure. Accelerometers send output through analog signals, which are then converted via an ADC converter into digital signals by the DAQ system. The DAQ system records this data, which, when using specialized software that interprets the data, gives engineers the ability to track and analyze shock and vibration measurements.

Get detailed information on our products by downloading our catalog.

View Catalog

How to Measure Shock & Vibration Using Accelerometers

To measure shock and vibration, accelerometers must be securely mounted on key points of the equipment and aligned with the expected motion direction; they should be positioned where vibrations or shocks are most likely to occur.

After installation, the accelerometer is calibrated to verify its sensitivity and that it matches the application’s specific needs; it also guarantees that output signals can be accurately translated into meaningful, actionable information. Once calibrated, the sensor is then connected to a DAQ system, initiating the data capture process for analysis.

Key Applications of Accelerometer Data Acquisition

Accelerometer data acquisition is used across industries. Some of the key applications include:

Performance & Evaluation Tests

Products require performance and evaluation tests before they are released to the market. Performance and evaluation tests are subject to strict rules, thus, prototypes are built and subjected to rigorous performance testing. There are a variety of performance tests, including: drop tests, impact testing, transportation testing, and vibration testing.

These tests evaluate the reliability and durability of parts and products by subjecting them to vibration in the actual operating environment. In addition to the durability of the product itself, the durability of the packaging material is also subject to testing.

Predictive Maintenance

With accelerometers continuously monitoring equipment, companies can spot early signs of wear, like unusual vibrations or shock; these early warnings allow maintenance teams to work before a failure occurs, preventing costly downtime and reducing the need for expensive replacements. Catching problems early on means machines stay running longer and operations run smoothly without unexpected interruptions.

Quality Control

In manufacturing, accelerometers are used to maintain product quality by monitoring the vibration levels of production machinery. Consistent vibration patterns indicate proper functioning, while abnormal patterns may signal issues that must be addressed.

Structural Health Monitoring (SHM)

Accelerometers are used to conduct modal analysis on the integrity of priority infrastructure, like bridges and subway stations; with these sensors measuring vibrations and shocks, engineers can determine whether or not a structure is experiencing stress that could lead to failure.

Discover more about this product.

Click here to book your demo.

Industrial Use Cases

Aerospace

In the aerospace industry, accelerometers measure the vibrations and shocks experienced by aircraft during flight and ground operations. These sensors help monitor components, such as engines and fuselage, and keep them within safe operating limits.

Structural Health Monitoring

In structural health monitoring, accelerometers are embedded in or attached to buildings, bridges, and other infrastructure to measure vibrations caused by factors like wind or traffic. By analyzing this data, engineers can detect early warning signs of structural degradation; this gives them the chance to take preventive measures that help avoid costly repairs or catastrophic failures.

Consumer Electronics & Wearable Technologies

Accelerometers have become foundational in the function of many consumer electronics, including smartphones, smartwatches, and fitness trackers. They use accelerometers to measure movement and orientation, improving features like step counting, heart rate monitoring, and activity tracking.

Smartwatches, for instance, rely on accelerometer data to track a user’s physical activity throughout the day. By continuously measuring motion, these devices can determine the number of steps taken and calories burned and even monitor sleep patterns.

Conclusion

Accelerometers help monitor the health of machinery and infrastructure in real time as measuring shock and vibration is key to keeping things running. With KEYENCE’s high-precision accelerometers and advanced data acquisition systems, you can easily collect the data you need to make wise decisions and boost your operations.

Contact KEYENCE today to explore our solutions. Optimize shock and vibration monitoring with high-precision accelerometers today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us