Data Acquisition (DAQ)

Monitoring Power Consumption for Sustainability & Troubleshooting

-

Tags:

- Renewable Energy

Key Takeaways

- Monitor machine-level power to detect load drift early and prevent production disruptions.

- Use real-time tracking (voltage, current, power factor, etc.) to enable condition-based maintenance.

- High-resolution logging captures inrush currents and brief events for precise troubleshooting.

- Correlate electrical data with temperature, vibration, and strain to quantify energy-saving impact.

Modern-day industrial facilities rely on equipment that draws power in different ways throughout the day, and those shifts affect everything from throughput to operating costs. A focused approach to power consumption monitoring gives teams the visibility needed to keep machines running smoothly and reduce unnecessary usage. When production and maintenance staff understand how each machine behaves under load, sustainability goals become easier to reach, and troubleshooting becomes faster and more precise.

The Importance of Monitoring Power Consumption in Modern Manufacturing

Manufacturing equipment rarely draws the same amount of power from one hour to the next. Load demand rises during startup, levels off during steady production, and changes again when wear or misalignment develops. Without power consumption monitoring, those patterns go unnoticed, and small issues can build up until they disrupt production. Tracking real usage at the machine and line level gives engineers a clearer picture of how equipment behaves under real conditions. It becomes easier to spot drifts in consumption, confirm whether a machine is operating as expected, and identify systems that use more energy than planned.

Real measurements also support planning. When teams know how much power each part of the process requires, they can manage resources with greater accuracy. This level of visibility supports both uptime and long-term performance because changes in electrical behavior often appear before a machine slows or fails. A consistent monitoring routine creates stronger awareness across the facility, tightening process control and strengthening overall performance.

We’re here to provide you with more details.

Reach out today!

How Power Consumption Monitoring Drives Sustainability in Facilities

Sustainability in manufacturing depends on understanding how energy is used during each step of the process. Power consumption monitoring plays a central role because it highlights where energy waste occurs and how often it happens. Machines that run at higher loads than expected contribute directly to higher utility spending and increased emissions. When those load changes become visible, teams can take action that reduces consumption without interrupting output.

Many facilities also face seasonal shifts in energy usage, and those changes are easier to manage when real historical data is available. A machine that runs smoothly in cooler months may draw more power in the summer due to environmental conditions or added ventilation loads. Monitoring long-term consumption patterns helps operators adjust schedules and plan maintenance during times that minimize unnecessary energy use. This approach supports broader sustainability efforts by lowering demand, stabilizing performance, and reducing the facility’s overall environmental impact.

Key Benefits of Real-Time Power Usage Tracking for Operational Efficiency

Real-time power usage analysis gives teams a sharper view of how equipment behaves throughout the day. Power Analysis includes inputs like:

- Instantaneous Power (active, inactive, apparent)

- Integrated Energy (active, reactive, apparent)

- Current / Phase Voltage / Line Voltage

- Power Factor for single and 3-phase wire systems

Even small variations in voltage or current can change how motors, drives, and control systems perform. When those variations are captured in real time, operators can respond before the change affects production, as a sudden spike may point to an emerging mechanical load, while a gradual increase may signal wear or buildup that needs attention.

This level of visibility also supports targeted maintenance, so instead of relying on fixed intervals, teams can focus on equipment that shows early signs of drift in its energy efficiency profile. That leads to fewer surprises and longer equipment lifespans. Real-time tracking also provides confirmation after repairs or upgrades. When consumption returns to expected levels, teams can validate that the issue has been resolved.

Discover more about this product.

Click here to book your demo.

Tools and Technologies for Effective Power Consumption Monitoring

Modern monitoring systems give manufacturing teams the flexibility to track voltage, current, and power across multiple points in the facility. High-speed data logging technology helps capture fast electrical events and creates a clear record of how each machine behaves under load. These tools convert raw electrical signals into usable information that maintenance and engineering teams can reference during troubleshooting or process improvement.

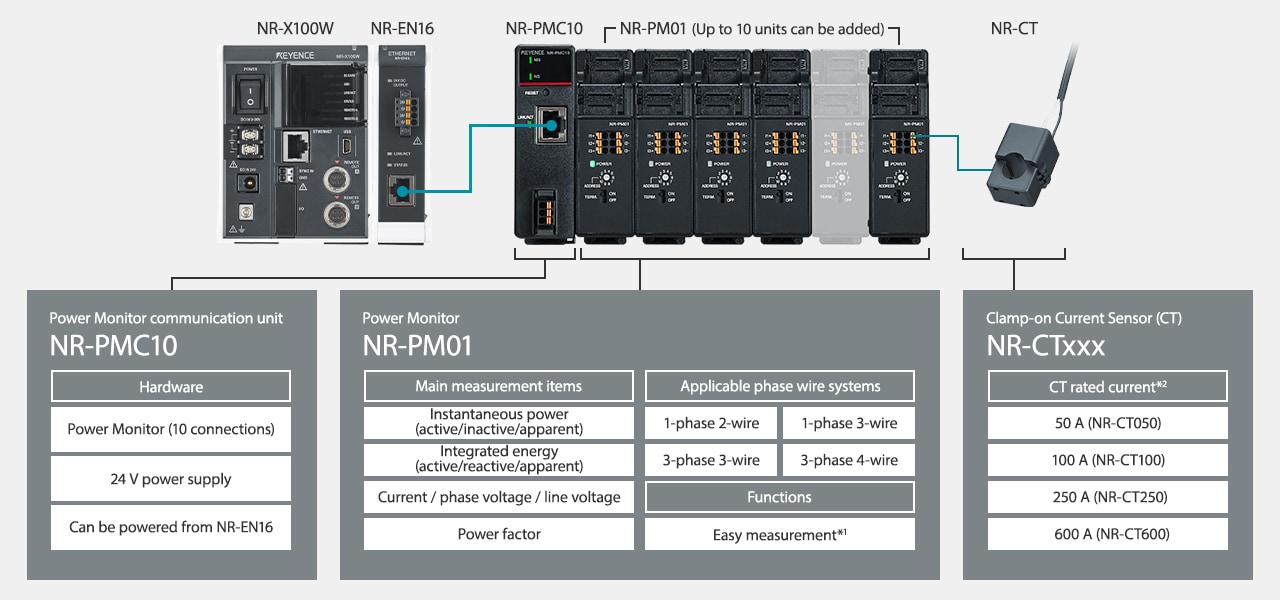

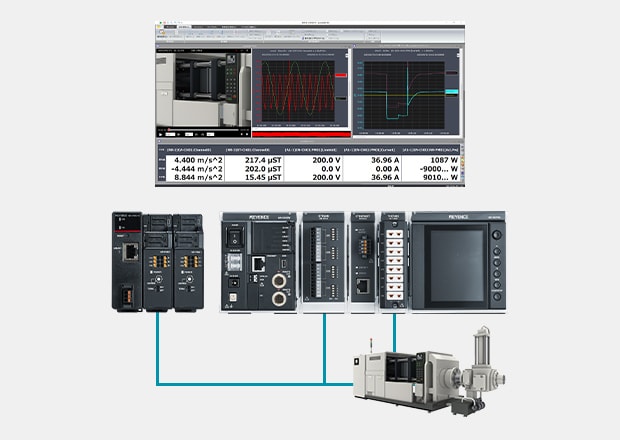

KEYENCE's NR-X100 Multi-Input Data Logger has modular hardware. By using our Power Monitoring/ Consumption module, the NR-PMC10, a user can log the amount of electricity used by each device can also be measured simultaneously with other data. This data can include:

- Temperature

- Vibration

- Sensor Data

- Strain / Load Cell

- Current/Voltage

With the NR-X100, the data collection required for equipment monitoring and energy-saving measures can be achieved using one device.

Effective power consumption monitoring also depends on collecting high-resolution data. When sampling rates are high, even brief disturbances (like inrush currents, voltage dips, or intermittent faults) are recorded accurately. This gives operators a precise view of how often irregular behavior occurs and whether it follows a recognizable pattern. The more accessible this data is, the easier it becomes to support energy-related initiatives, guide maintenance decisions, and strengthen sustainability programs throughout the facility.

*1. This function measures energy using only a CT. You can calculate the energy from the current value using the set voltage/power factor.

*2. A general-purpose CT (up to 2000 A) can also be used.

Common Power-Related Issues in Manufacturing and How to Troubleshoot Them

Power-related problems appear in many forms. One of the most frequent issues is voltage fluctuation. Low voltage can cause relays to chatter or motors to run unevenly, while sudden surges can damage sensitive electronics or shorten component life. Troubleshooting power issues becomes more straightforward when voltage and current data are available, because the electrical signature of each event gives clues about its source.

Overloaded circuits show up when several machines share a supply that’s already close to its limit. Breakers start tripping, and the line stops without warning. Tracking real power usage gives teams a clearer look at which equipment is pulling a heavier load than expected and whether a circuit is carrying more than it should.

Loose connections, worn insulation, and aging terminals also cause irregular electrical behavior. These faults create brief jumps or drops in current that are difficult to see during a quick inspection. Logged power data picks up those small shifts and helps technicians narrow the problem to a specific wire, panel point, or component.

Motors and drives add their own load changes. A fan that’s clogged or a bearing starting to drag will raise current draw long before the motor slows. Power usage analysis makes that early rise visible, giving maintenance a chance to correct the mechanical cause before it becomes a failure. In automation systems, even a short voltage dip can disrupt PLC inputs or drive signals. When power data lines up with the timing of those faults, teams can tell whether the issue came from wiring, a device, or the control program.

How Power Consumption Analysis Improved Facility Sustainability

Equipment can be combined freely based on voltage, vibration, temperature, and power

When teams track how machines consume power over time, improvements become easier to plan and measure. A facility may discover that certain machines consume more energy during specific material runs or after long periods of continuous operation. These patterns provide opportunities to schedule cooling periods, shift production loads, or update components that cause higher consumption. Once adjustments are made, power consumption monitoring shows whether the change actually reduced usage.

Facilities that use power data to guide decisions often see reductions in peak demand, smoother operation, and fewer unexpected outages. These benefits strengthen sustainability in manufacturing by building a process that naturally reduces waste.

Start Monitoring Power Consumption for Improved Sustainability!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How Does Power Consumption Monitoring Benefit Sustainability Efforts?

Monitoring reveals where energy is used, wasted, or drifting from expected levels. When teams see these patterns in clear data, it becomes easier to reduce unnecessary load, improve energy efficiency, and support sustainability in manufacturing.

What are Common Power Issues That Need Troubleshooting in Manufacturing?

Voltage fluctuations, overloaded circuits, loose connections, motor imbalance, and irregular current draw appear often in factory environments. These issues create unstable machine behavior and can lead to downtime.

Which Tools Help Monitor Power Usage Effectively in Factories?

High-speed data loggers and multi-channel measurement systems are most often used to capture voltage, current, and power behavior in real time. They help teams perform accurate power usage analysis and support sustainability and troubleshooting efforts throughout the facility.

We’re here to provide you with more details.

Reach out today!