Optical Comparator (Profile Projector)

Dimensional Inspection for the Aerospace Industry

KEYENCE’s Image Dimension Measurement Systems are ideal for precision measurements necessary for the aerospace industry. Aerospace metrology has unique specifications, strict regulations, and a small margin of error. To help comply with these, KEYENCE created unique measuring instruments that help improve metrology for aerospace.

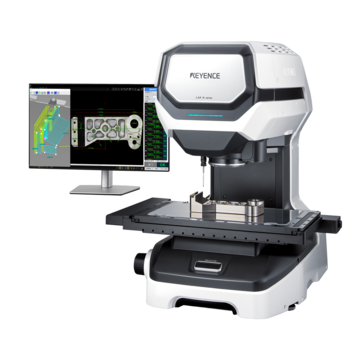

Automated Image Measurement System

Optical comparators are standard aerospace metrology instruments for small parts. However, most of these aerospace measuring instruments are manual optical comparators that require tedious adjustments and long hours of measuring.

Moving away from manual systems, KEYENCE created automated image measurement systems for aerospace metrology. Automated image measurement systems cut measuring time and data analysis down to seconds. No more manual labor, training for new systems, or slow data entry.

KEYENCE’s aerospace precision measurement systems are:

- IM-8000 Series Image Dimension Measurement System

- LM Series High Accuracy Image Dimension Measurement System

- LM-X Series Multisensor Measurement System

We’re here to provide you with more details.

Reach out today!

Place and Press for Measurement

The IM-8000 Series Image Dimension Measurement System is so simple that it requires just two steps—place and press.

To use the IM or LM Series, place up to 100 parts onto the stage and press the measure button. Unlike conventional optical comparators, there is no need to orient or focus the small aerospace components and parts repeatedly for the perfect angle and to get every edge. The IM measures up to 300 features in seconds.

Place and press can be used with these aerospace measuring instruments:

- IM-8000 Series Image Dimension Measurement System

- LM Series High Accuracy Image Dimension Measurement System

- LM-X Series Multisensor Measurement System

Get detailed information on our products by downloading our catalog.

View Catalog

Accuracy and Repeatability

Regardless of the operator, the aerospace measuring instruments consistently produce the same results, which is an absolute necessity for aviation measuring tools. The aerospace measuring instruments can do this because they auto-adjust and do not need to have a manual orientation of the part placed on the stage. It doesn’t matter who, what, where, when, or how someone places a part on the stage.

KEYENCE’s Aerospace measurement solutions with the place and press capability:

- The IM-8000 Series has +/- 2μm accuracy

- The LM Series has +/- 0.7μm accuracy

- The LM-X Series has +/- 0.7μm accuracy

Curious about our pricing?

Click here to find out more.

Telecentric Lens

A telecentric lens is a lens that views a component with large and distortionless depth of field. The lens keeps constant magnification with a 2D view to combat perspective angle error from different part heights. All KEYENCE image measurement systems feature telecentric lenses.

Discover more about this product.

Click here to book your demo.

Inspection Reports

KEYENCE’s precision measuring systems collect data and automatically generate inspection reports to meet your AS9100 requirements and streamline your measurement processes. These reports include feedback on trends and variations as well as statistical values like maximum, minimum, average, Cp, Cpk, and more. This information is stored within the software of the metrology device, but can help meet your company’s digital initiatives by easily sharing with other facilities that require real-time access via system networking. All of KEYENCE’s systems also meet your data security protocols through on-board security measures and seamless integration with existing methods.

We’re here to provide you with more details.

Reach out today!

Import CAD Data

The aerospace metrology image measurement instruments include an optional feature of importing CAD data for comparison to real parts to ensure the most detailed models.

As metrology for aerospace continues to evolve, precision measurements will continue to play a pivotal role. KEYENCE’s Image Dimensions Measurement Systems will keep advancing in order to provide optimal solutions.

Questions about our systems and how they can help with your aerospace applications? Contact KEYENCE today to talk to one of our specialists.