Optical Comparator (Profile Projector)

What is the Extrusion Process? Types & Advantages Explained

Key Takeaways

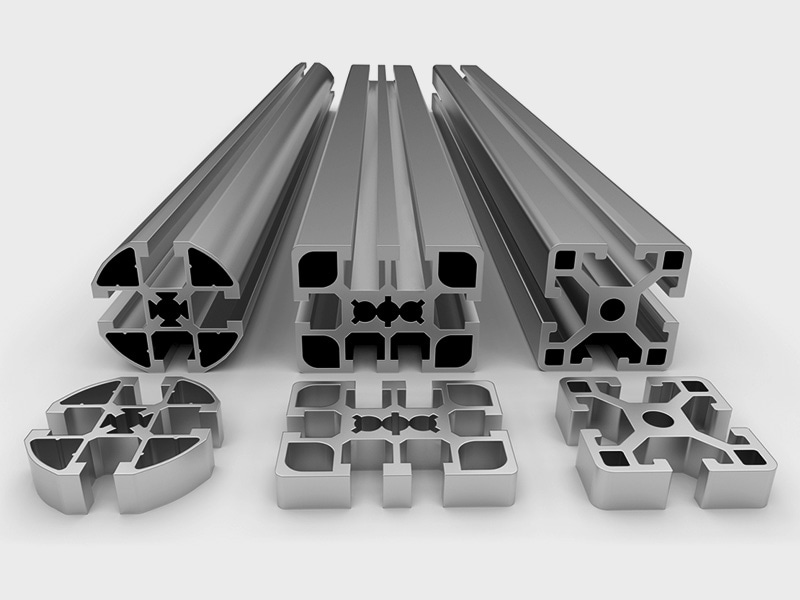

- Extrusion pushes material through a die to form continuous profiles (rods, tubes, sheets).

- Core steps: billet/die prep → ram extrusion → quench cooling → cut removal → finishing.

- Types: hot (heated die, complex shapes), cold (no heat, less oxidation), friction (heat by rotation).

- Trade‑offs: hot allows complexity but causes oxidation; cold saves energy but limits shapes.

- Widely used across industries; in‑process dimensional inspection ensures quality of extrusions.

Curious about extrusion or how the extrusion process works? In this article, we’ll explain exactly what extrusion is, describe the extruding process, and discuss the advantages and disadvantages of extruding.

What is Extrusion?

Extrusion is a metal-forming technique that shapes a material by pushing it through a die. The extruding process mimics toothpaste pushed out of its tube and forming into the shape of the tube’s opening.

We’re here to provide you with more details.

Reach out today!

What Is Extrusion in Manufacturing?

The extrusion process stands as one of the most efficient manufacturing methods for creating continuous profiles and shapes. This technique transforms raw materials into precise cross-sectional forms through the application of controlled pressure and temperature. Production in various industries has been transformed by manufacturing extrusion methods.

This procedure is used by modern facilities to consistently create thousands of pieces per day. The process involves pushing heated or room-temperature materials through apertures that have been carefully made. Every time the die is passed through, identical shapes that adhere to exact dimensional specifications are produced.

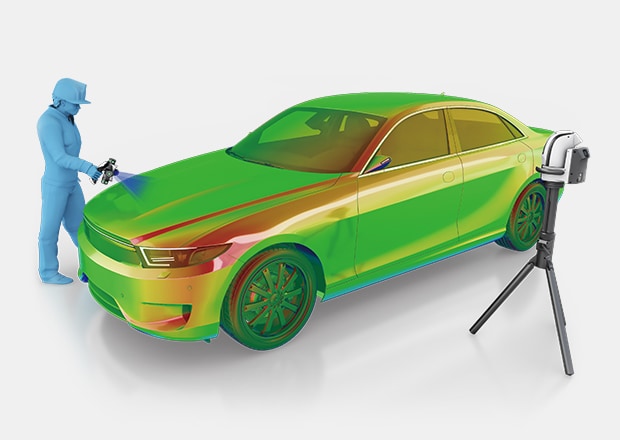

Every extruded part is guaranteed to meet specifications through quality control techniques such as 3D measurement tools. These cutting-edge solutions preserve production standards and identify flaws early. Better results are obtained when conventional extrusion methods are combined with contemporary measurement tools.

Extrusion Terms

When discussing this process, many common terms arise. Here are a few:

Billet

A billet is a cylindrical metal that is processed in the extruding process.

Die

A die is a manufacturing medium that shapes or cuts materials. In the extruding process, the die is the machine a billet is pushed through and comes out with a new shape.

Extrusion Ramp

The extrusion ramp is the foundation that the billet slides along when going through the extrusion machine.

Hollow

A hollow is a final extrusion shape that has one or more openings. Examples of hollows are square, rectangular, or circular tubes.

Puller

The puller is the mechanical arm that pulls the extruded shape out of the die.

Quench

Quench is the cooling process of shooting the extruded part with cold air or cold water after heating in the extruding process.

Ram

A ram is a machine that adds pressure to the billet to move through the die.

Semi-Hollow

A semi-hollow is a final extrusion shape with a partially enclosed opening—for example, a C channel.

Solid

A solid is a type of final extrusion shape with no enclosed openings—for instance, a rod, beam, or angle.

We’re here to provide you with more details.

Reach out today!

How Does the Extrusion Process Work?

There are numerous steps that are used by manufacturers. Here is a breakdown of each:

Step 1: Die and Billet Preparation

Before extrusion occurs, die and billet preparation are required for optimal results. Preparation in hot extrusion includes heating the die oven between 400 and 500 degrees Celsius (approximately 750 to 930 degrees Fahrenheit) and placing the billet inside.

In the case of another extruding process, like cold or friction extruding, this involves lubricating the extrusion ramp or metal for easier entry into the die.

Step 2: Billet Extrusion

In step two, a ram adds 100 to 15,000 tons of pressure to the billet and pushes it through the die. The method in which the ram adds pressure depends on whether the extruding process is hot, cold, or frictional.

As the billet comes out of the die, a puller attached to the extrusion machine will slowly start pulling the billet along the extrusion ramp to make room for more to come out.

Step 3: First Cooling

After the billet comes out of the die, the extrusion machine quenches the new part. The quenching solidifies the shape and prevents deformities.

Step 4: Die Removal

Since the billet comes out of the die passage still attached to the original form, it needs to be cut by a hot saw to remove it from the die. After removal, the newly formed material cools to room temperature.

Step 5: Finishing

Last in the extruding process is finishing on the formed part. Finishing may be cutting the extruded shape into smaller pieces, removing oxidation, or shining.

We’re here to provide you with more details.

Reach out today!

Types of Extrusion

Common Types of Extrusion Methods

In addition to the three main forms of extrusion, there are several specialized variants that meet specific production requirements. Impact extrusion forces material around a punch to produce hollow objects. Hydrostatic techniques lower friction during material flow by applying fluid pressure.

Every version has special advantages for various uses. Certain materials or shape requirements make certain processes more effective. Manufacturers can select the best strategy for their projects by being aware of these possibilities.

Hot Extrusion

Hot extrusion uses a heated die oven for the extruding process. The heat makes the billet malleable, which is particularly effective for helping shape hard metals.

Examples of metals used for hot extrusion:

- Magnesium

- Copper

- Steel

- Advantages

-

The malleability from heat is a massive advantage to heat extrusion over other methods. Since the metal is more malleable, the hot extruding process produces more metal in less time, and can make more complex shapes than alternative methods.

- Disadvantages

-

Although the heat is an advantage in some terms, it can also be a disadvantage. The heat from the die creates an oxide layer that requires different finishing processes on the extruded part. These additional finishing steps take up time, energy, and costs.

Cold Extrusion

Cold extrusion isn’t necessarily cold; it just doesn’t use heat for the extrusion process. Because of this, cold extrusion is used on softer metals and uses more lubrication.

Examples of metals used for cold extrusion:

- Aluminum (and alloys)

- Lead

- Tin

- Advantages

-

An obvious advantage to cold extrusion is the absence of heat surfacing issues like oxidation layers. That’s not the only advantage, though. The cold extrusion also doesn’t use as much energy or time as the hot extrusion because it doesn’t require heating the die.

- Disadvantages

-

Although cold extrusion avoids the detrimental effects of heat, it is a limiting extruding process. Because of the lack of heat, the metal isn’t as malleable. In turn, there is a higher cost for lubrication and limited shapes that cold extrusion can achieve.

Friction Extrusion

Friction extrusion uses frictional heating to move the material through the die and into an extruded part. The metal is forcibly and quickly rotated against the die hole to create heat for increasing malleability. Once the metal generates enough heat to be malleable, it moves through the die.

- Advantages

-

Friction extrusion is the best of both worlds of cold and hot extrusion. Similarly to hot extrusion, it uses heat to make metals malleable for complex shapes and a seamless process. However, it doesn’t use the heating-up energy that hot extrusion requires.

- Disadvantages

-

Although friction extrusion avoids using machine energy for heat, it still uses a lot of energy to make friction between the billet and the die. Also, friction extrusion requires extra finishing because of the formation of heat oxidation.

Discover more about this product.

Click here to book your demo.

Applications Across Industries

Due to their adaptability, manufacturing extrusion techniques are essential in various industries. Automotive manufacturers employ extruded parts for interior components, bumpers, and frames. These components provide outstanding strength while reducing the vehicle's weight.

For structural beams and architectural components, extruded materials are used extensively in construction. The aerospace industry demands precise tolerances that extrusion can deliver consistently. Medical device manufacturers appreciate the smooth surfaces and biocompatible materials possible through careful process control.

Consumer electronics benefit from extruded housings and heat sinks that manage thermal loads effectively. Food processing equipment uses extruded components that resist corrosion and maintain sanitary conditions. Each industry adapts the basic extrusion process to meet specific performance requirements.

Extruded aluminum profiles are used in marine applications for corrosion-resistant boat hulls and deck structures. For strength and weight economy, railway systems rely on aluminum car bodies and extruded steel rails. Extruded pipes and fittings that can tolerate high temperatures and pressures are necessary for oil and gas operations.

In the fields of renewable energy, extruded parts are used in wind turbine and solar panel frames. Furniture producers use aluminum extrusion technologies to build frames that are both lightweight and sturdy. Sports goods manufacturers use specific extrusion methods to create equipment handles, ski poles, and bicycle frames.

For weather protection, telecommunications infrastructure depends on extruded cable conduits and antenna housings. Extruded ducting and ventilation components are used in HVAC systems to ensure effective airflow.

Advantages of Extrusion Processes

Cost efficiency ranks among the top benefits of using extrusion for manufacturing. The process creates minimal waste compared to machining operations that remove material. High production speeds allow manufacturers to meet large volume demands quickly.

Dimensional accuracy remains consistent throughout long production runs. This reliability reduces quality control costs and minimizes the number of rejected parts. The smooth surface finish often eliminates secondary operations like grinding or polishing.

Complex cross-sections that would be challenging to accomplish using conventional techniques are made possible by design flexibility. Features such as internal channels or varying wall thicknesses can be added by engineers. These features create new avenues for weight loss and product innovation.

Compatible Materials & Metals

The choice of material is essential to the success of extrusion processes. Due to its superior formability and resistance to corrosion, aluminum alloys remain the most widely used option.

While steel grades offer stronger properties, they also demand higher temperatures. For certain applications, copper provides superior electrical conductivity. Beyond conventional metals, the spectrum of potential goods is increased by plastics and composites.

Each material brings specific challenges and benefits to the extrusion process. Temperature control becomes critical with heat-sensitive polymers. Die design must account for material flow characteristics and shrinkage rates. CMM systems help verify that different materials meet dimensional specifications.

Comparison to Other Forming Techniques

A number of considerations come into play when contrasting hot vs cold extrusion with other manufacturing techniques. Although forging produces stronger parts, it greatly reduces shape complexity. Although casting enables complex designs, it necessitates a lot of secondary machining.

Rolling techniques are effective for sheets but ineffective for producing hollow portions. Solid stock machining results in significant waste and increased material expenses. By fusing material efficiency with design freedom, extrusion fills these voids.

3D scanning technology enables precise comparison between extruded parts and other manufacturing methods. This analysis helps engineers select the most appropriate technique for each application. The data supports informed decisions about cost, quality, and production volume requirements.

Extrusion in Manufacturing Process

The extruding process is vital for shaping metals to make beams, tubes, angles, rods, and C channels. From forming the pipes under our sinks, picture frames holding precious family photos, and the bleachers we sit on, the extruding process is limitless.

In aerospace, interior design, medical devices, food, automotive, and more, there’s no industry that doesn’t benefit from the extruding process. The versatility in processes, from cold to hot to friction, means that there is always an extrusion process that fits a forming project.

KEYENCE’s IM-X1000 Series provides accurate and instant measurement solutions to extrusion manufacturers. Give us a call at 1-888-539-3623 to discuss your needs or questions.

Discover more about this product.

Click here to book your demo.

Related Downloads

We asked our customers why they switched from conventional technologies to the IM Series Instant Measurement System. See how this system adds value to any inspection process.

![IM-X Series Case Study [Laboratory testing]](/img/asset/AS_162512_L.jpg)