Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the Film and Sheet

KEYENCE sensors offer solutions for a variety of process improvement and quality control challenges in the film and sheet industry. Whether a film/sheet is transparent, opaque, thick or thin, the solutions below can help your process run more efficiently.

The film and sheet industry is defined by its need for precision and uniformity, meaning advanced measurement systems and methods are a must. Measurement sensors play a crucial role in ensuring product quality, efficiency, and adherence to strict industry standards, thus enhancing the overall efficiency and cost-effectiveness of the entire production process.

Choose Case of Measurement Sensors for the Film and Sheet

The Importance of Precision Measurement in the Film and Sheet Industry

While there is no official definition on what separates a film from a sheet, both are relatively thin, flat, and uniformly shaped… especially when compared to material plates.

Measuring film thickness and width is extremely important when it comes to maintaining uniformity. Even slight deviations in dimensions can significantly affect a film or sheet’s performance.

Therefore, the production process relies on measurement sensors to ensure these dimensions stay within specified tolerances. In addition to enhancing product quality, precise measurements lead to greater cost-effectiveness of the entire process by minimizing material waste and optimizing production.

Precise measurement also ensures compliance with industry standards, ensuring correct thickness and width so the product meets regulatory requirements and customer expectations.

We’re here to provide you with more details.

Reach out today!

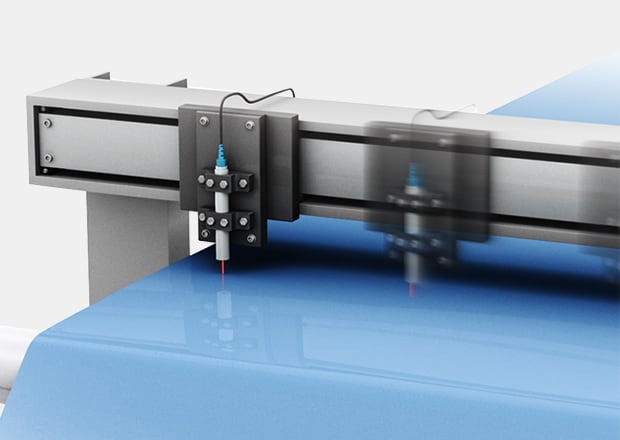

Wet Coating/Film Thickness

Measure transparent film immediately after coating using the SI-F Series. By traversing the sensor, you can get real-time process feedback across the width of the web to improve overall quality while minimizing waste.

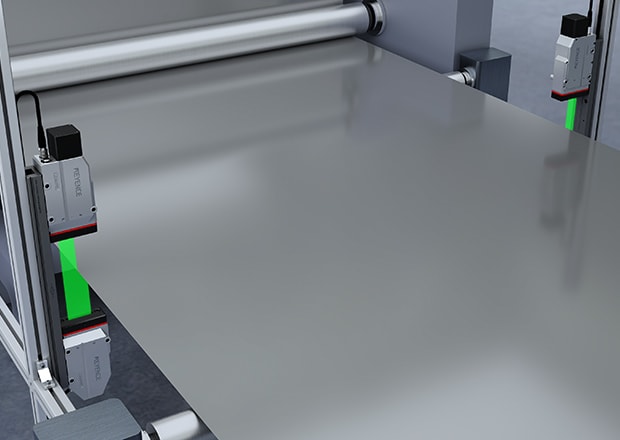

Sheet Width and Meandering Measurement

Measure width and meandering with a single setup. Placing an optical micrometer on each end of the web provides a great low maintenance solution thanks to their high speed and accuracy.

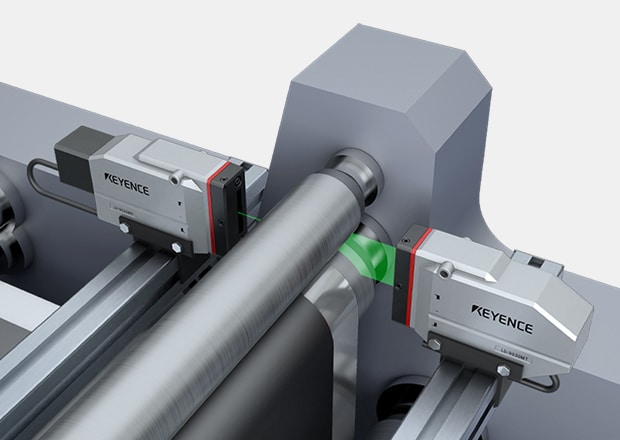

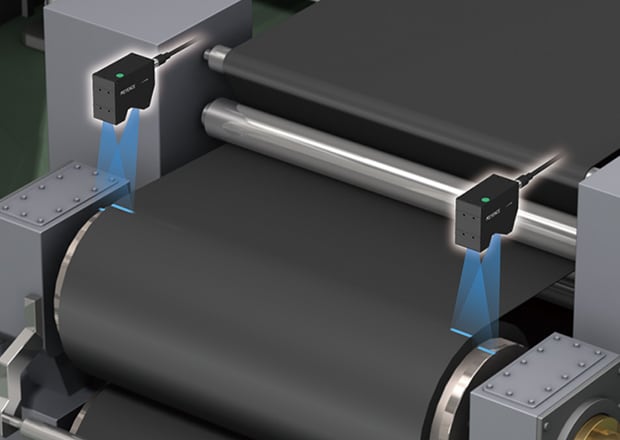

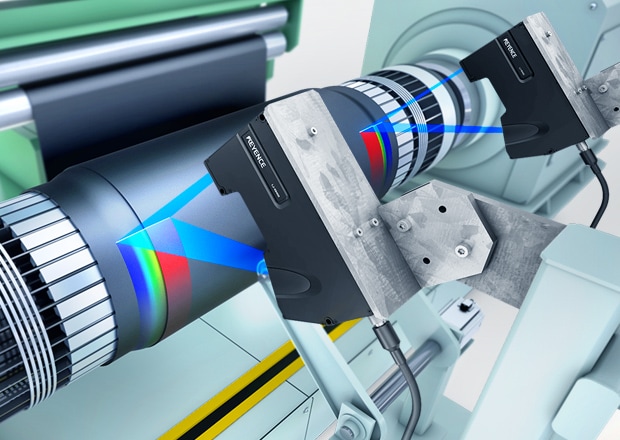

Roller Gap Control (Film/Sheet Thickness)

By monitoring the gap between coating rollers at one or both ends, it's possible to maintain tight control over sheet thickness. The LS-9000 Series can measure gaps as small as 10 µm, so this solution works for even extremely thin films.

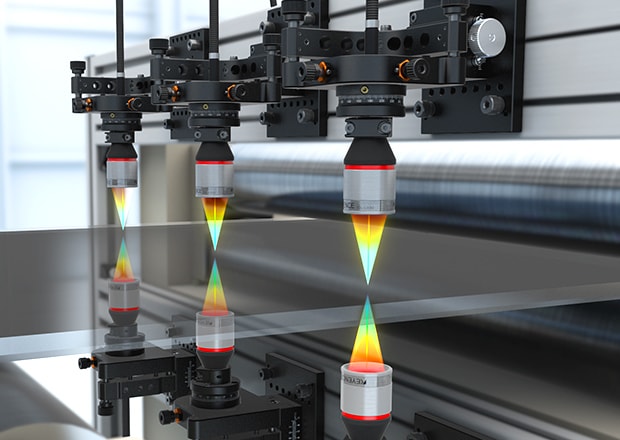

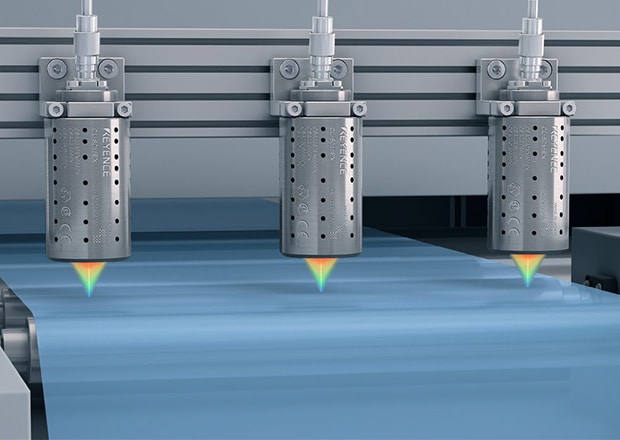

Sheet Thickness Measurement

Using non-contact sensors makes it simple to get 100% inspection for sheet thickness. The CL-3000 Series can measure thickness of any material, regardless of color or surface finish, without having to adjust the settings.

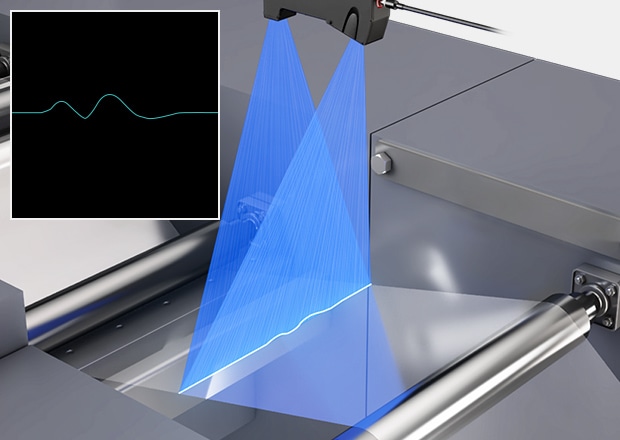

Film Wrinkle Detection

By profiling the entire surface of a film, it's possible to reliably detect wrinkles. Laser profilers provide a great alternative to cameras here because you can rely on height changes in addition to contrast changes to pick up on defects.

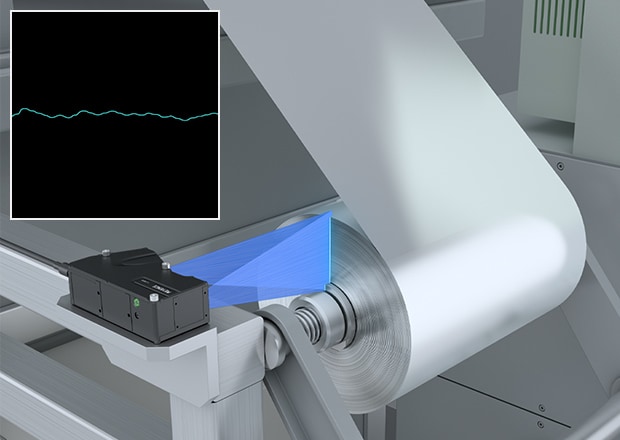

Roll End Profile

2D Laser Profilers can inspect the end profile of a roll as the sheet is wound to prevent telescoping/dishing. With in-process inspection, issues like wrinkles and meandering during unwinding can be avoided, leading to overall improved efficiency.

Extruded Rubber Thickness and Width Inspection

Measure the width and thickness of rubber sheets with a single system. By using a laser profiler on each edge of the sheet, you can monitor the height difference between the roll and the material to get thickness and edge profile, in addition to sheet width.

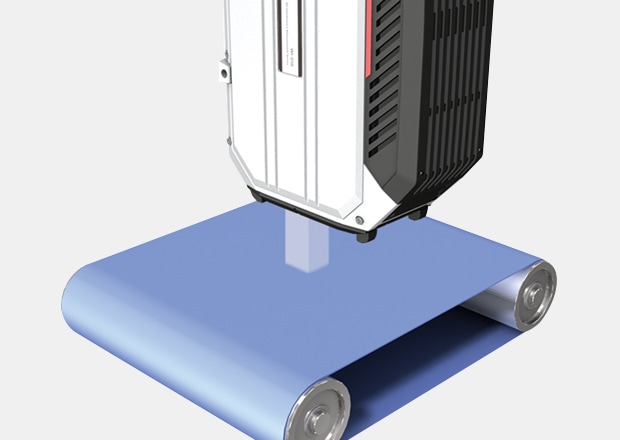

Foreign Matter and Defect Detection

Complete 3D inspection of belt surfaces for small irregularities or foreign matter to prevent quality issues. The WI-3000 Series is a 3D displacement sensor that can quantify these defects to help inform preventative maintenance decisions.

Sheet Thickness, Width, and Edge Profile

Free-form planes allow the system to pick up on deviations from the typical contour of a surface. This makes stable defect detection possible, even for targets with complex shapes.

Measurement in Explosion-Proof Environments

The CL-S015EX complies with the technical standards required for devices that use optical radiation and has obtained IECEx, ATEX, and NRTL/ACO certification.

Role in Quality Control and Inspection

Generally speaking, precise measurement and inspection systems are indispensable when it comes to quality control in film and sheet manufacturing. Measurement sensors and the systems they’re integrated with continuously monitor and inspect various product characteristics and properties. This ensures that the end products adhere to the specified requirements and predetermined standards.

Sensor selection is also critical due to the fine thickness of these materials. Using physical sensors might impede the measurement process since the physical contact can deform or even damage the extremely thin object of measurement. Thus, non-contact sensors provide a more viable measurement approach.

Discover more about this product.

Click here to book your demo.

Sensor Selection

As stated, measuring the thickness of these materials has been traditionally done using physical tools and sensors. However, modern laser scanning methods for the film and sheet industry take such measurements without any physical contact with the material surface.

This is where 1D confocal laser displacement sensors, such as the KEYENCE CL-3000 Series, come into play. By positioning these sensors on both sides of the material, opposite to each other, the measurement system can calculate the thickness by subtracting the cumulative displacement from the sensor’s overall distance with ±0.2 µm accuracy.

The same thing applies to 2D triangulation laser displacement; it can be used to measure the thickness and width of film and sheet products. The LJ-X8000 Series provides an in-line multi-point measurement with the world’s fastest sampling rate at 64,000 images per second.

Integration with Automation and Control Systems

Integration with automation and control systems provides continuous quality control, with sensors feeding vital data from the production lines into various measurement and logging systems. This provides automated feedback within the control system, which enables autonomous real-time adjustments and optimization of the manufacturing process.

Additionally, the data collected from these sensors proves to be invaluable for predictive maintenance and process analytics. This ultimately reduces downtime, cuts costs, and enhances the quality of film and sheet products.

Is your organization looking to improve your film and sheet production process? Look no further than KEYENCE's 1D confocal laser displacement sensors and 2D triangulation laser displacement systems. Contact us today for a consultation on how we can transform your production line!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity

![Automated Measurement and Inspection Examples [Films and Sheets]](/img/asset/AS_119833_L.jpg)

![Quick Guide To Process Improvements [Plastic/Rubber/Film Industry]](/img/asset/AS_46841_L.jpg)