Measurement Sensors

Dimension Measurement

Displacement Measurement

Non-Contact Measurement Sensors for Explosion-Proof Environments

Several industries — especially those dealing with volatile chemicals — often handle hazardous, explosive materials. Any combustion in these environments can be devastating.

That’s where non-contact measurement sensors designed for explosion-proof environments play a crucial role in maintaining safety while also providing accurate, operation-specific data. This guide will discuss explosion-proof measurement sensors, the dangers of using out-of-spec sensors, the important measurement applications in hazardous manufacturing and production environments, and all the benefits of using an explosion-proof sensor.

What Makes a Sensor Explosion-Proof?

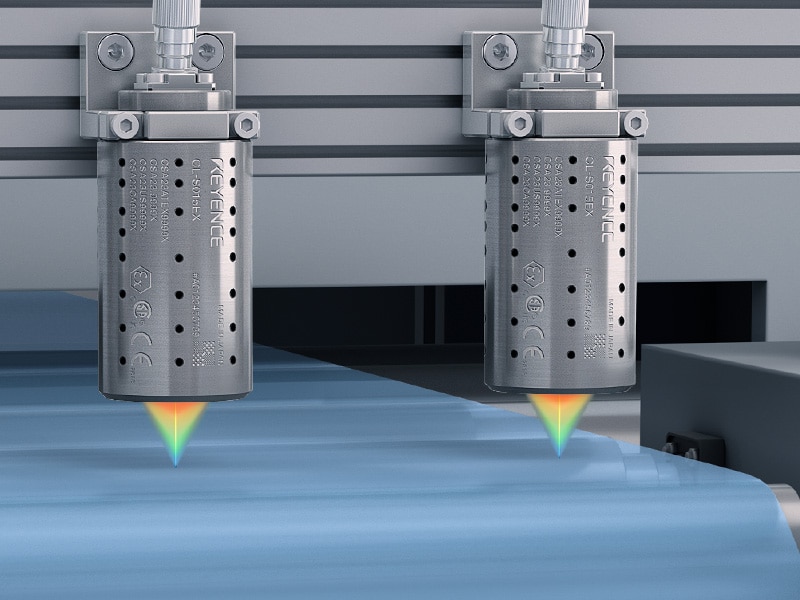

For environments that need explosion-proof equipment, KEYENCE offers the CL-S015EX confocal displacement sensor. These sensors are mostly used to measure the height of an object at a specified distance, and the sensor heads don’t contain any electrical components. As a result, they are explosion-proof and safe for use in hazardous areas. This type of design has several advantages over other explosion-proof measurement sensors offered by the competition.

For example, these sensors are reliable and highly accurate for measurements in challenging conditions. Their design also features a corrosion-resistant enclosure, which ensures safety and efficiency. Additionally, the lack of electrical components inside the sensor head eliminates any potential energy release (such as sparks and arcs) that could potentially ignite the surrounding atmosphere.

They’re also ATEX and IECEx certified and meet international safety standards, thus ensuring compliance with regulatory requirements while also providing peace of mind to users and business owners.

It should be noted that the optical unit, which does contain electrical circuitry, is considered “associated equipment,” and it’s not suitable for installation in hazardous areas. Instead, the light is fed into the sensor head through an optical fiber and separated with a dedicated pass-through.

We’re here to provide you with more details.

Reach out today!

Dangers of Using Out-of-Spec Sensors

Using out-of-spec sensors that aren’t designed with explosion-proofing in mind can lead to catastrophic consequences across numerous industries, including the food industry, which generally uses safe materials (flour is explosive). Though uncommon during normal operation, non-certified sensors can produce sparks, heat, or electrical arcs that can ignite flammable gasses or dust, leading to explosions and fires.

This poses a major safety risk, as it not only has the potential to cause significant damage to equipment and facilities but can also cause harm to employees and personnel. Non-certified sensors can also provide inaccurate measurement data caused by exposure to extreme temperatures, humidity, or corrosive substances… resulting in data errors, incorrect decision-making during operation, and unsafe conditions.

Lastly, using out-of-spec sensors in hazardous environments puts your company at risk of legal penalties, fines, and increased scrutiny from regulatory bodies governing your industry.

Out-of-specs sensors often aren’t capable of withstanding the harsh conditions of hazardous production environments, leading to frequent failures and costly repairs and replacements. They’re often the cause of unplanned downtime, which leads to massive productivity losses and financial impacts due to frequent interruptions in production processes.

Important Measurement Applications in Explosion-Proof Environments

Explosion-proof sensors are essential parts of critical measurement applications within the chemical and petrochemical industries, where these sensors are used to monitor the levels of flammable liquids and gasses in storage tanks and pipelines.

These sensors ensure the safe operation of machinery and equipment and prevent dangerous leaks and overflows. They are also used in the oil and gas industries, where they measure pressure, temperature, and flow rates in drilling, refining, and transportation processes necessary for nominal operation.

Explosion-proof measurement sensors are also used in mining to detect and monitor combustible gases and dust in underground mines. These sensors prevent explosions and ensure the safety of miners and personnel.

They’re also used in the pharmaceutical industry, where they ensure precise control of environmental conditions, especially in manufacturing processes that involve volatile substances. This helps maintain product quality and safety.

Lastly, they’re also used in the food and beverage industry, where they measure the temperature and humidity in food processing and storage, where dust or vapors from ingredients pose an explosion risk. We already mentioned flour, which is more explosive than gunpowder and 35 times more combustible than coal dust—this is why industrial bakeries use explosion-proof particulate matter sensors.

Discover more about this product.

Click here to book your demo.

Benefits of Using the CL-S015EX

For environments that need explosion-proof equipment, KEYENCE offers the CL-S015EX confocal displacement sensor. These sensors are mostly used to measure the height of an object at a specified distance, and the sensor heads don’t contain any electrical components. As a result, they are explosion-proof and safe for use in hazardous areas. This type of design has several advantages over other explosion-proof measurement sensors offered by the competition.

For example, these sensors are reliable and highly accurate for measurements in challenging conditions. Their design also features a corrosion-resistant enclosure, which ensures safety and efficiency. Additionally, the lack of electrical components inside the sensor head eliminates any potential energy release (such as sparks and arcs) that could potentially ignite the surrounding atmosphere.

They’re also ATEX and IECEx certified and meet international safety standards, thus ensuring compliance with regulatory requirements while also providing peace of mind to users and business owners.

It should be noted that the optical unit, which does contain electrical circuitry, is considered “associated equipment,” and it’s not suitable for installation in hazardous areas. Instead, the light is fed into the sensor head through an optical fiber and separated with a dedicated pass-through.

Why Choose KEYENCE?

KEYENCE is the world’s leading provider of precision technologies for measuring, quality assurance, and quality control applications across numerous industries, including those dealing in hazardous materials and environments.

Our explosion-proof measurement sensors are designed to withstand harsh operational environments while also offering easy integration into existing systems, with straightforward installation and minimal maintenance requirements, which significantly reduces downtime and enhances overall productivity. Don’t hesitate to contact KEYENCE to learn more.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

![Automated Measurement and Inspection Examples [Power Semiconductors/Inverters]](/img/asset/AS_111935_L.jpg)

In recent years, the demand for power semiconductors, power modules, and inverters has increased in applications such as electric vehicles. Read about multiple applications putting KEYENCE’s latest laser displacement sensors to good use in production lines of these parts, where quality and safety are both necessary.

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity