Measurement Sensors

Dimension Measurement

Displacement Measurement

Laser Sensors for the Wood and Lumber Industry

Measure twice, cut once; that’s the motto of the lumber industry. From lumber thickness measurements to defect detection, laser sensors cut down on material waste and improve efficiency.

Get detailed information on our products by downloading our catalog.

View Catalog![Automated Measurement and Inspection Examples Building Materials [Flooring material/External wall/Roof]](/img/asset/AS_118581_L.jpg)

Key Applications of Measurement Sensors in Lumber

Laser lumber sensors provide the most precise and accurate measurements. These devices address challenges in lumber processing and help produce higher-quality products. Some key applications of this technology are:

Dimensional Scanning

Laser sensors are used to precisely measure the dimensions of logs and lumber. This helps operators make accurate cuts. Yield is also optimized, and unnecessary material loss is reduced. This is a crucial benefit in modern, cost-conscious lumber processing.

Lumber Profiling

By creating detailed profiles of logs, advanced lumber profilers allow for better material utilization. Laser lumber sensors are particularly valuable in the high-value timber trade, where one wrong cut can directly impact profitability.

Lumber Thickness Measurement

Maintaining a consistent lumber thickness is required for delivering a quality product. Laser measurements offer precise data that minimizes errors and prevents reworks.

Wood Thickness Detection

When it comes to measuring wood thickness on fast-moving production lines, laser sensors offer unparalleled accuracy. Their ability to function in and withstand harsh environments, like dusty sawmills, keeps operations running and provides consistent results.

Defect Detection

The capabilities of a laser lumber system not only improve the quality of finished lumber but can also identify defects early in production. These sensors can identify internal flaws and knots. By using 2D laser measurements, they can also detect surface irregularities.

The applications of laser sensors have had a transformational impact on the wood industry, helping them achieve higher productivity while maintaining strict industry standards.

We’re here to provide you with more details.

Reach out today!

Measuring Lumber Thickness

Without an accurate lumber thickness measurement, operators cannot produce quality and consistent wood products. Laser sensors are able to provide precise, non-contact measurements that outperform traditional methods. These sensors are positioned above and below the lumber on a conveyor system. Dual opposing sensors account for vibrations and irregularities which deliver reliable results even in high-speed production environments.

Laser sensors also stand out in demanding environments like sawmills where, even with the dust and debris, the sensors still perform. These sensors also monitor other equipment like air blowers to maintain accuracy under these conditions. This ensures thickness is maintained even on boards with knots and cracks.

Measuring Wood Thickness

Accurately measuring wood thickness, particularly for raw logs, is crucial in converting timber into usable lumber. A laser measure here ensures a precise assessment of log diameters and profiles. This enables the sawmill to maximize its lumber output. 3D sensors can create detailed profiles of each log to act as a guide for the milling process, which results in less operational waste.

Benefits of Using Measurement Sensors in Lumber Processing

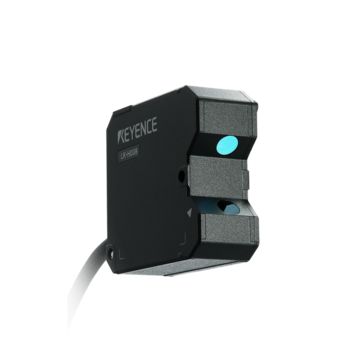

Laser lumber measurement systems like KEYENCE’s CL-3000 Series provide consistent product quality as they can maintain strict dimensional tolerances while minimizing material waste. These systems play an important role in lumber operations, especially in environments focused on large-scale building material manufacturing.

With an increased focus on sustainability, these laser lumber systems are working to reduce material waste, which directly impacts the environment. Integrated laser sensors offer improved precision and efficiency for this eco-friendly effort.

If you’re ready to take your lumber processing to the next level, contact KEYENCE today. We have over 30 years of expertise in sensor technology and offer solutions for lumber mills of any size.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity