Measurement Sensors

Dimension Measurement

Displacement Measurement

Measurement Sensors for the LED Lighting Industry

The LED industry has entered a stage in which 0603 LEDs are considered giant, despite the fact they’re only 1.6 mm × 0.8 mm in size. LEDs have become so small that their components are 10x to 100x smaller than previous models.

Measurement sensors are vital in the LED industry. They ensure accurate monitoring and control of several parameters during production and testing. These sensors assess factors like brightness, color temperature, and energy efficiency, enabling manufacturers to maintain high-quality standards.

Manufacturing these new LEDs requires extreme miniaturization. Traditional measurement methods are becoming less viable, as many can’t accurately measure such small components. As a result, manufacturers are turning towards non-contact measurement sensors — such as laser profilers and laser displacement sensors — as precise, non-invasive replacements.

Choose Case of Measurement Sensors for the LED Lighting Industry

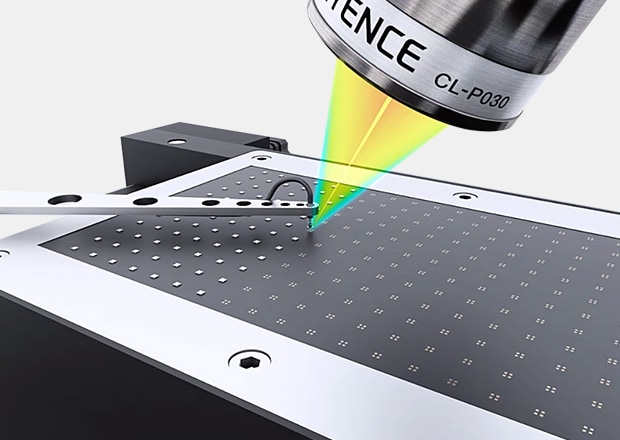

Chip Mounter Z-Axis Control (LED)

Distance to the PCB on which the chip is to be mounted will be measured to control mounting height.

The CL-3000 Series uses a multi-color confocal measurement principle, which enables high-precision measurement of large areas. The spot diameter stays the same throughout the entire range, enabling high accuracy even if the distance to the target changes.

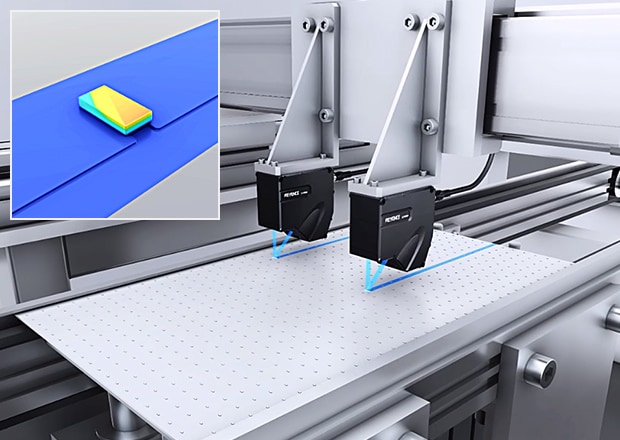

Chip Tilt Inspection (LED)

The PCB surface is scanned with the LJ-X8000 Series to measure the height of mounted LED chips. The measured in-plane height data can be used to inspect not only chip mounting height, but tilt as well.

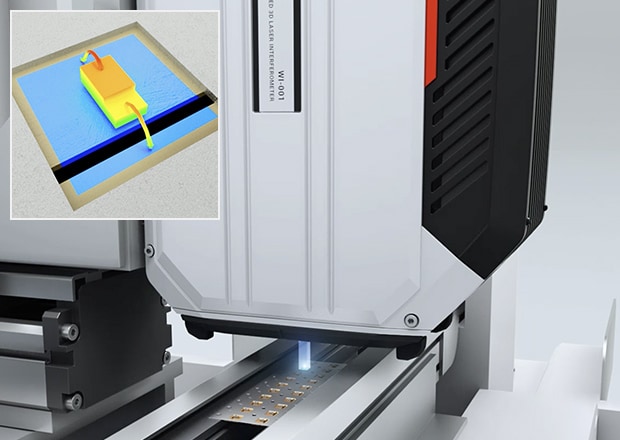

Measuring Wire Bonding Height (LED)

This system inspects the height of the bonding wire vertex. Due to the coaxial measurement principle, the WI-5000 Series is ideal for in-plane batch measurement. The WI Series is capable of measuring a wide range of material types/finishes, including highly reflective wire vertices. In addition, the minimum measurement pitch is 4 microns, allowing for inspection of small diameter wires.

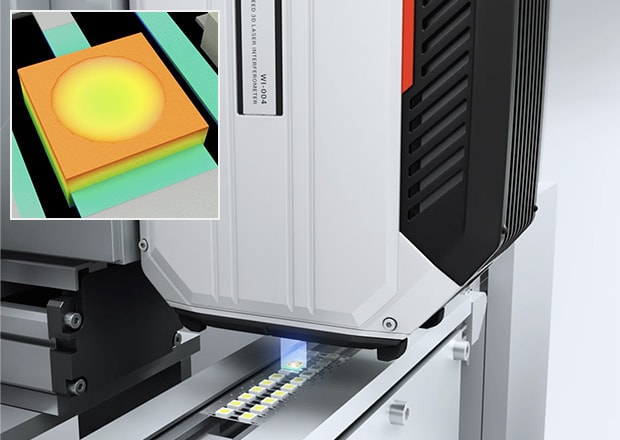

Measuring the Height of Fluorescent Substance

This system measures the height of LED potting resin during the manufacturing process. Due to the power of the white-light interferometry measurement principle, the WI-5000 Series is able to measure almost any material. The intuitive and easy to use software makes repeatable in-plane batch measurement of resin vertices extremely simple.

The Role of Laser Snapshot Sensors in the LED Industry

The LED industry depends so much on accuracy and efficiency, especially during manufacturing and quality control processes. 3D laser snapshot sensors are becoming increasingly important in the LED industry due to their ability to provide fast, accurate, and precise measurements of LED components. These sensors capture explicit, high-resolution 3D images ensuring even the smallest defects are identified without slowing down production. Snapshot sensors are especially effective in recognizing problems that are challenging to spot, such as irregularities in LED placement and surface flaws, which, if undetected, can impact the quality and performance of LED products.

Curious about our pricing?

Click here to find out more.

How 3D Snapshot Sensors Improve LED Industry Applications

3D snapshot sensors for LED industry applications are crucial. By using these sensors, manufacturers gain access to real-time, three-dimensional data that improves their inspection potential and promotes product consistency. Unlike early formal 2D sensors, 3D snapshot sensors deliver depth information, which is critical for assessing the geometry, spacing, and alignment of LED components. This technology enables manufacturers to distinguish and rectify defects more efficiently, reducing waste and ensuring consistent, high-quality LED output.

How Industrial Snapshot Sensors Enhance LED System Inspections

In industrial LED system applications, snapshot sensors are needed for demanding quality checks. These industrial sensors can scan complex LED assemblies faster and accurately, providing a constructive solution for inspecting a wide range of LED products. Industrial snapshot sensors improve LED system inspections by providing precise measurement data that ensures every component meets strict quality standards. With the ability to inspect multiple aspects of LEDs at once, these sensors streamline quality assurance processes, ultimately enhancing the reliability of LED systems.

Key Features of Laser Measurement Tools for LED Analysis

The ongoing miniaturization efforts to reduce the scale of LED chips and packages while maintaining their effectiveness has made laser measurement tools indispensable within the LED industry, thanks to their high accuracy and fast scanning speeds.

Here are some of the most important features associated with LED measurement systems for LED analysis:

Highly Accurate 3D Measurements

The need for precision in the LED industry, particularly with the emergence of mini- and micro-LEDs, can’t be overstated—particularly because light-emitting diodes are everywhere now, from general lighting applications to advanced electronics. The latter often imposes stringent specifications, which underscores the importance of highly accurate 3D measurements in the LED industry.

KEYENCE’s WI-5000 Series 3D interference LED measurement sensor exemplifies the capabilities required for such applications, enabling batch in-plane measurements on the same axis with the minimum measuring pitch of 4 µm. This allows for extremely accurate 3D measurements and surface scanning of LED and PCB components with very high precision.

Fast Response Time and Real-Time Monitoring

LED manufacturing (especially on the mini and micro scales) has taken the shape of CPU production, pointing towards a speedy production process. Fortunately, on top of their accuracy, KEYENCE’s WI-5000 Series provides very fast response times, allowing real-time monitoring of production processes.

This enables manufacturers to monitor the production process and make necessary adjustments to the process to maintain product quality. The ability to quickly measure and analyze mini- and micro-LED components as they’re being manufactured significantly reduces the risk of defects, ensuring that the production process remains effective.

Compatibility with Different LED Types and Configurations

The LED industry encompasses a wide range of LED types and packages, each with its own specific use case and performance criteria. The importance of precise LED measurements in this industry is further underscored by the introduction of high-definition screen displays based on mini- and micro-LED technologies, which rely on sub-mm packaging and configurations.

LED sensors offer exceptionally high precision, often measured in the single-digit µm range, making these sensors highly versatile and capable of scanning various LED types and configurations. Furthermore, their high precision offers increased adaptability to even smaller packages, which is crucial for reliable implementations in an industry where miniaturization is one of the key drivers of success.

Manufacturers can now use a single LED sensor type to measure different LED productions ranging from micro-LEDs present in screen displays to small indicator lights and large lighting panels.

Discover more about this product.

Click here to book your demo.

Laser Measurement Tools

Laser measurement sensors for the LED Lighting industry bring a whole new level of precision, speed, and versatility perfectly suited for the ongoing miniaturization of electronic components. LED sensors are great at providing highly accurate 2D and 3D measurements, ensuring that the products meet strict quality standards.

Optimize Your LED Analysis with Precision Measurement Using KEYENCE LJ-S8000 Series Sensors

KEYENCE LJ-S8000 Series sensors exemplify the precision and efficiency demanded by the LED industry. These 3D laser snapshot sensors for the LED industry offer a wide variety of inspection capabilities, including dimensioning, appearance, and shape detection. By utilizing motor-driven scanning technology, the LJ-S8000 Series can achieve ultra high-speed and ultra high-accuracy inline inspections with imaging speeds as fast as 0.2 seconds. It also provides differentiation capabilities without the need for external lighting or complex setups.

By providing detailed surface profiles and rapid data acquisition, LJ-S sensors support manufacturers in achieving greater quality assurance, minimizing defects, and optimizing LED performance.

As the LED industry continues to grow and the technology continues to evolve, the role of LED sensors and LED measurement systems in precise measurements will become even more pronounced.

If you’re looking to implement laser measurement and LED sensors into your existing manufacturing process, don’t hesitate to contact KEYENCE and inquire with our team about possible integrations with your current system.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity