Measurement Sensors

Dimension Measurement

Displacement Measurement

Overcoming Challenges in High-Speed Production With Inline Quality Control Systems

Every product ever produced should undergo a quality control inspection, and each product has particular dimensions and qualities it must meet before it gets passed on to the consumer. However, the same cannot be said for every quality control inspection. Human-led inspections are often at the mercy of their operator’s skill and level of fatigue.

In the following, we’ll discuss quality control processes, their issues, and how modern quality control systems can improve your organization’s manufacturing operating efficiency and product quality.

The Role of Quality Control Systems in High-Speed Production

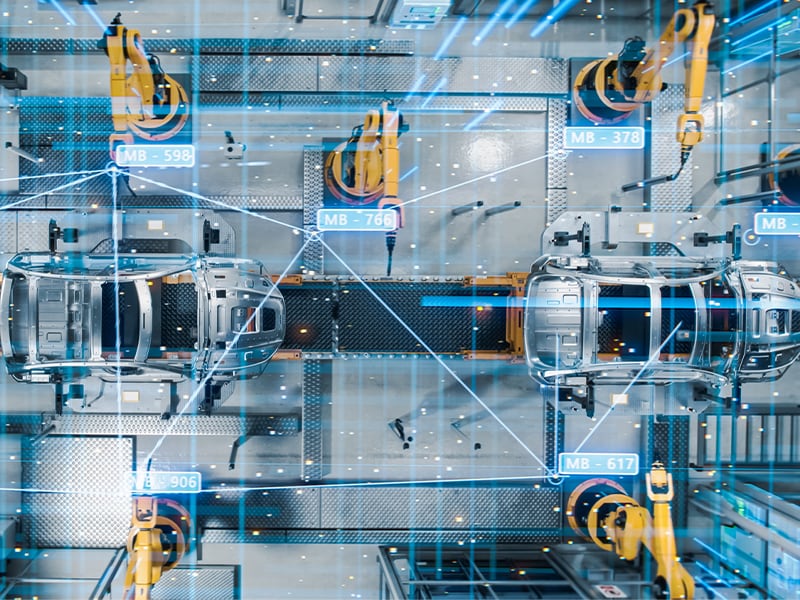

Thankfully, inline quality control systems are designed to support the quality control process so that every product continues to meet its specifications, but without running the risk of human oversight. Inline quality control systems are particularly effective as they can be built directly into existing production lines and allow for continuous monitoring without interrupting production flow. Operators are given real-time data that helps them detect defects as they happen, allowing them to take immediate corrective action.

Common Issues in High-Speed Production & Their Impact

There are quite a few issues that high-speed production lines face that can hinder efficiency and product quality. One of the most significant issues that inline quality control systems fix is the reliance on manual inspection methods. Traditional quality checks are often performed offline. This method has struggled to keep up with high-speed production, which has led to delays or errors in identifying defects.

Another challenge for high-speed production lines is inconsistent quality checks; minor defects can go unnoticed without an inline quality control system continuously monitoring them. When they are identified, it may be too late to address them in an effective manner, which can lead to costly downtime and production delays.

High-speed production lines often face labor shortages and skill gaps, further exacerbating these challenges. As the demand for skilled labor increases, the available pool of qualified workers has not kept up, and this shortage puts additional stress on the production line. Maintaining consistent quality across the production process becomes more difficult with fewer skilled workers. As a result, human-led quality control efforts may be compromised. However, due to the automation of inline inspection systems, the effects of a labor shortage are less stressful for manufacturers as they do not rely on the presence of an operator to find defects.

Inline quality control systems provide a solution by automating the inspection process, by helping spot defects early, and allowing production to continue without disruption. These inline systems help improve the speed and consistency of quality checks while minimizing the risk of errors. This helps maintain a more efficient and reliable production line.

We’re here to provide you with more details.

Reach out today!

How Inline Quality Control Workflows Improve Efficiency

One of the key benefits of inline quality control is that its systems are automated to monitor production constantly and have the ability to deliver real-time feedback. As soon as a defect is detected, the system immediately alerts operators and deals with issues as soon as they occur, preventing defects from spreading throughout the production line.

Inline systems are also advantageous in that they help eliminate bottlenecks caused by manual inspection processes. In high-speed production, any delay in quality control can create a ripple effect that slows the entire process down. Inline quality control systems keep inspections running without disrupting the flow of production. These automated systems also reduce the need for offline inspections, speeding up the overall process and reducing the chance of errors due to operator fatigue.

Incorporating inline quality control directly into a production line’s workflow allows manufacturers to maintain their operations while keeping up with high-quality standards.

Key Technologies Used in Modern Quality Control Systems

Modern inline quality control systems rely on several advanced technologies to stay precise and accurate. These technologies have been designed to work together to support production quality and efficiency:

Laser Measurement Systems

Laser-based sensors offer highly accurate measurements of part dimensions, surface quality, and alignment; these systems are commonly used in industries like automotive and semiconductor manufacturing, where precision matters most. Laser 2D and laser 1D scanning technologies allow continuous, non-contact measurements, ensuring fast and accurate quality control.

Machine Vision Systems

Machine vision technologies use high-resolution cameras and specialized software to inspect parts for defects and dimensional inaccuracies that are invisible to the human eye. They are used to improve detection rates in high-speed production environments.

IoT Integration

The Internet of Things (IoT) enables smart manufacturing by connecting machines, sensors, and control systems across the production line. IoT-enabled inline quality control systems provide real-time data analysis, predictive insights, and proactive quality management, helping manufacturers identify potential issues before they become costly problems.

Cloud-Based Data Management

Cloud technologies allow for seamless data sharing and collaboration between teams, helping them take advantage of the monitoring and analysis of production data. Cloud-based management is supported by a centralized platform that tracks quality metrics used for better decision-making and improving overall operational visibility.

Inline quality control systems let manufacturers monitor the entire production process in real time. Equipped with advanced sensors and machine vision systems, inline quality control systems can provide the most up-to-date data and updated inspection data, which leads to detecting defects early and making sure that products meet the highest standards of quality.

Discover more about this product.

Click here to book your demo.

Best Practices for Implementing Inline Quality Control in Fast-Paced Environments

Implementing inline quality control in a fast-paced production environment requires careful planning and consideration of production goals. First and foremost, the system must be built into the existing production workflow as this embeds quality control into every step of the production process.

Automation Systems

Automation is a key component of any effective inline quality control system: the more inspection tasks that can be automated, the faster the process becomes. Automated systems remove the human error factor and provide consistent results.

Real-Time Data Collection

Real-time data collection is an important component when it comes to maintaining control over quality inspections. Manufacturers can continuously monitor production data to identify trends and spot potential issues; the constant flow of data allows operators to make informed adjustments without downtime. Up-to-the-minute data also gives them the ability to improve workflows and efficiency, all while eliminating bottlenecks and rework.

Ongoing Training

Training staff to work alongside automated systems is also important. While inline systems handle much of the inspection, operators must undergo training to interpret system alerts and take corrective action when needed. This combination of automation and human involvement keeps production lines operating efficiently without having to sacrifice quality.

Preventative Maintenance

Predictive maintenance must be incorporated into any inline quality control system; by monitoring equipment performance alongside throughput, manufacturers can identify potential issues with machinery before they cause production delays or expensive repairs.

Future Trends in High-Speed Production & Quality Assurance

As manufacturing evolves, so do the technologies that drive high-speed production and quality assurance. Artificial intelligence and machine learning are increasingly used in inline quality control systems, looking to overtake inspection tasks completely and free up operators for higher-value tasks. These systems learn by analyzing data and identifying patterns, enabling a system to predict quality issues before they occur; this predictive nature thus allows manufacturers to address quality concerns before they reach the end of production.

While cloud-based solutions are currently in use, they are set to improve connectivity and data analytics further. This allows teams to monitor production lines remotely and in real time from anywhere in the world. Sustainability is also shaping the future, with inline systems helping reduce waste and scrap by detecting defects early, supporting both high-quality standards and environmental goals.

Conclusion

Want to incorporate inline quality control systems into the future of your production line? Look no further! KEYENCE has the solutions to enhance production efficiency and reduce defects using advanced quality control systems. KEYENCE has been an industry leader since 1974 and has decades of experience in factory automation and quality assurance, and we can help you!

If you're ready for solutions to improve your production process and keep you ahead of the curve, contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity