Measurement Sensors

Dimension Measurement

Displacement Measurement

Enhance Accuracy—Choose the Right Measurement Tools Today!

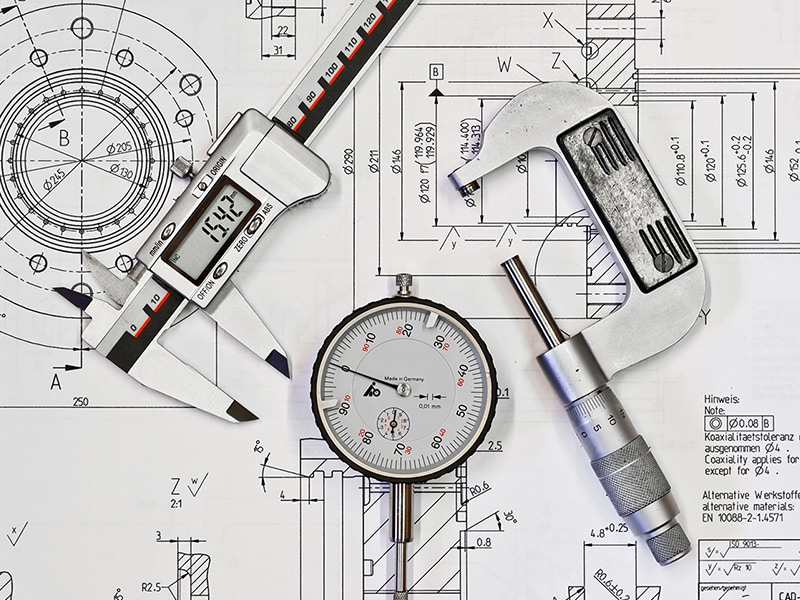

Accuracy of measurements is a staple in industrial applications because it verifies precision in manufacturing and quality control. Choosing the right measurement tool improves efficiency and product reliability.

What Is Measurement Accuracy and Why Does It Matter?

Measurement accuracy refers to how closely a measured value matches the true value; high accuracy reduces errors, resulting in better product quality. It is often confused with precision, but while precision refers to the repeatability of results, accuracy guarantees correctness.

In industries like medical device manufacturing, inaccurate measurements can result in improperly fitted implants or surgical tools that fail to perform correctly.

In semiconductor fabrication, microscopic errors can render a microchip defective, causing production delays and financial losses. Non-contact measurement systems help maintain accuracy by minimizing physical interference and improving reliability in automated processes.

Whether in the automotive, medical, or semiconductor industries, accurate measurements maintain compliance with strict quality standards.

We’re here to provide you with more details.

Reach out today!

Defining Measurement Accuracy in Industrial Applications

Maintaining the accuracy of measurement depends on environmental conditions, sensor technology, and calibration. Temperature fluctuations and vibrations can affect readings, making laser 2D and laser 1D sensors ideal for precision. These tools minimize external influences to maintain consistent performance.

Calibration is equally vital; without regular adjustments, even the best tools lose accuracy over time. In fast-paced manufacturing environments, types of distance sensors provide real-time accuracy, enhancing efficiency.

The Role of Accuracy in Quality Control and Manufacturing

Accurate measurements reduce defects and improve production efficiency and a poor precision-to-tolerance ratio can lead to wasted materials and costly rework. In industries like aerospace and electronics, even minor inaccuracies compromise product integrity.

For example, in automotive manufacturing, a poorly machined engine component that exceeds tolerance limits can cause performance failures or safety risks. Real-time measurement solutions improve manufacturing by integrating AI-driven analytics and IoT monitoring, which allows for instant corrections. 3D inspection technologies further refine quality control, verifying every component meets specifications before final assembly.

We’re here to provide you with more details.

Reach out today!

Understanding Tolerance in Measurement

Tolerance defines the acceptable margin of error in manufacturing. A 50 mm part with a ±0.1 mm tolerance must measure between 49.9 mm and 50.1 mm to be considered acceptable. Measure tolerance effectively to ensure reliable product performance.

There are multiple tolerance types, including:

- Dimensional tolerance: maintain physical size variations and remain within limits.

- Geometric tolerance: Controls shape accuracy and prevents form deviations.

- Positional tolerance: Ensures components like holes or slots align properly.

In precision manufacturing, laser displacement sensors and automated measuring systems help verify tolerances and reduce human error to improve consistency.

Find the Best Distance Sensor for Your Needs

KEYENCE offers precision measurement solutions that include: laser sensors, 3D inspection systems, and non-contact measurement devices. All of our tools are designed to improve efficiency and minimize measurement errors. From micron-level surface profiling to real-time dimensional verification, our advanced technologies support high-speed production lines, automated quality control, and complex material inspections.

Explore our guide now and find the best tools to improve the accuracy of measurements in your operations.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity