Optical Comparator (Profile Projector)

The Value of Instant Measurement in All Areas of Inspection

Key Takeaways

- Instant measurement boosts manufacturing speed, precision, and long-term cost savings.

- Three Instant Measurement types: automated optical comparators, high‑accuracy comparators, multisensor systems.

- Use IM-X at all QC stages: incoming, first‑article, in‑process, and final inspections.

- KEYENCE IM advantages: high throughput, micron/sub‑micron accuracy, automated reporting.

- User‑friendly integrated software shortens implementation and cross‑skill team adoption.

With efficiency being a top priority for the manufacturing industry, you can see why the speed and efficiency of instant measurement systems would be valuable. Although this tech has existed for quite some time, the capabilities of IM solutions have come a long way.

Utilizing instant measurement tools is immensely valuable, especially throughout various stages of the manufacturing process.

Let’s break down the value of an instant measurement system and how it will impact the manufacturing industry in the future.

Types of Instant Measurement Systems

There isn’t usually a one-size-fits-all solution when it comes to manufacturing technology. Given manufacturers' various requirements, this is no different when it comes to inspection tools. Nevertheless, it is easy to integrate instant measurement technology in one of three forms:

To choose the most effective equipment for your particular needs, understanding the types of instant measurement systems is essential, as is examining their distinctions and unique advantages.

We’re here to provide you with more details.

Reach out today!

Advantages of Instant Measurement Tools

Instant measurement tools like the automated optical comparator are capable of precision measurements, and they offer time savings in the form of automated reporting, multiple part inspection, and easy stats and analysis. The benefits of IM tools are vast, and their presence grows more prominent in the world of manufacturing everyday.

It is also important to highlight the role an instant measuring machine plays in each stage of the manufacturing process. Using this technology at various stages can speed up the process, offer versatility for different applications, and provide long-term cost savings.

Incoming Inspection

Seen as the initial stage of the quality control process, incoming inspection considers aspects like raw materials and sub-assemblies. For the most part, incoming inspection entails general inspection, testing, and measurement of the incoming items.

This part of the process commonly includes functionality testing, dimensional checks, and much more. You can find several suitable machines for this stage, with the automated optical comparator being a go-to choice for many manufacturers.

First Article Inspection

The first article inspection focuses on one or more parts at the early stages of production to compare them to the client's specifications. This helps reduce waste and guarantees that the manufactured parts match the client's specifications.

It is a vital step in the manufacturing process that, if everything goes well, eventually leads to subsequent production. However, it is far from the end, as there are going to be a few more stages in quality control before an order is sent out the door.

In-process Inspection

As production gets closer to actual distribution, in-process inspection, sometimes performed in batches, ensures that items moving down the production line are meeting their specifications. In short, in-process inspection focuses on examining various components in the middle of the production process.

This commonly includes time-based batch inspections and a fast-paced environment better suited for automated optical measuring instruments. An automated optical measurement device can easily handle this quality control stage as it can deliver quick results on multiple parts at a time with minimal effort.

Final Inspection

The most crucial part of quality control is at the very end before distribution. Final inspection is the last line of defense before a product makes it out the door. Examining individual parts, transportation damages, and any other potential errors is vital to the final inspection.

For the most part, the final inspection includes the following steps:

- Visual inspection

- Testing

- Measurements

If each part passes the inspection steps above, the distributed product should come out exactly as designed. For this stage of the inspection process, optical CMMs are extremely helpful. This device offers the mobility and accuracy that workers need during on-the-fly inspections.

For manufacturers that commonly deal with smaller parts, an image dimension measurement system is more than suitable for handling quality control. Overall, the final inspection should include detailed reporting, which can be easily generated by an instant measurement tool.

Get detailed information on our products by downloading our catalog.

View Catalog

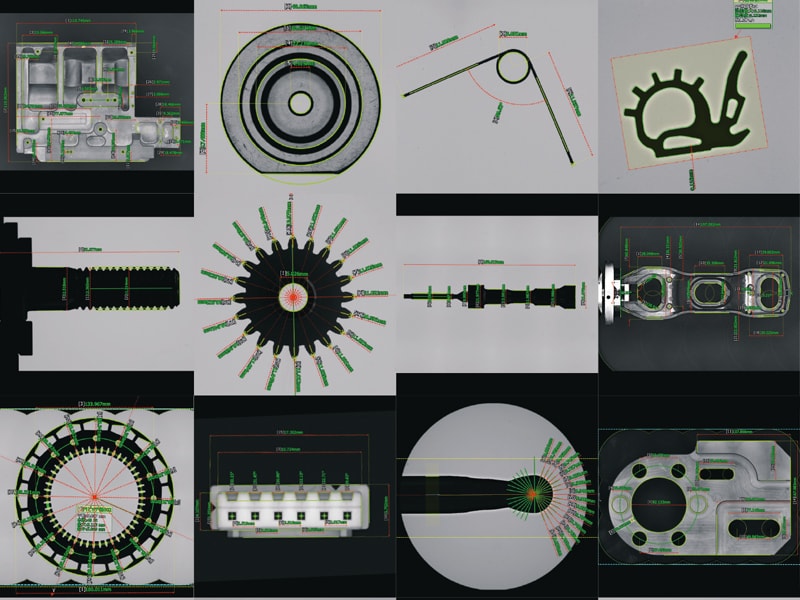

Features of KEYENCE’s Optical Comparator Instant Measurement Systems

KEYENCE's Instant Measurment Systems offer more than enough capability. Under optical comparator measurements, you'll find a modular system where you can pick what capabilties are needed for your inspection process.

- IM-X Series

- Automatically measures up to 1000 of the same part at one time

- Automatically measures up to 5000 part features in a second

- Measure parts within an 15.75 x 19.69 x 7.87 inch range

- Sub-micron-level accuracy

- LM Series

- Automatically measures up to 100 of the same part at one time

- Automatically measures up to 500 part features in seconds

- Measure parts in a 9 × 5 × 2 inch range

- Sub-micron level accuracy

One key feature that makes these systems so effective is the integrated software. Since this proprietary software may be new to many, there is bound to be a learning curve for those unfamiliar with how it works. However, KEYENCE’s simplified software is user-friendly, making implementation easy. Manufacturing teams are made up of different age groups and skill levels, so this is an important consideration.

Each system boasts unique use cases alongside KEYENCE’s well-known quality, accuracy, and reliability. These image-measuring instruments are breaking down the barriers between efficiency and learning curves. Each optical comparator design holds a significant use case in the manufacturing market and is leading the way in what innovation should look like down the road.

The Bottom Line

As seen over recent years, image and multisensor measurement systems have become the norm across many industries. Many manufacturers are evaluating their inspection processes to see how instant measurement systems like KEYENCE’s can improve operations.

Integration of instant measurement speaks for itself, as efficiency, accuracy, and value-added capabilities are currently unmatched. If you want to reinvent or improve your quality control processes, contact us to learn more about how we can help.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

See common optical comparator application examples measured on the IM Series Instant Measurement System. Application examples include: turned parts, machined parts, springs, stampings, fasteners, gaskets, etc.