Optical Comparator (Profile Projector)

What is Metrology and How is It Used in Manufacturing?

Key Takeaways

- Metrology in manufacturing ensures dimensional uniformity and quality control across global production.

- Calibration and traceability are mandatory practices to validate measurements and share part history.

- Non-contact (optical) and contact (CMM) methods complement each other; multisensor systems handle complex parts.

- Environmental effects and operator changes are mitigated by temperature/vibration compensation and automation.

When considering what metrology is, it’s standard to define it simply as the study of measurement. However, applying metrology to manufacturing means more than that. Metrology is the study of what measurement means within a structure.

Everywhere you look, a manufacturer uses metrology to form the products you see. From the chair you’re sitting on to the device you’re reading this blog on, metrology had to be used to ensure each part adequately fits together. Metrology evaluates parts over time, like car parts that naturally shift. It is why manufacturers can inspect and adjust these shifts and make a product last longer.

Within metrology, there are several layers to learn—from international standards and manufacturer protocols to common metrology challenges and metrology tools. In this blog, we’ll dive into all of these intricacies and look at how it is used in manufacturing facilities.

What is Metrology in Manufacturing?

Standardization and uniformity are the principles of metrology in manufacturing—so international organizations, treaties, and regulations keep consistent metrology in manufacturing all around the world.

Even though two measurement systems are taught in different countries (the imperial system in the US and the metric system in most of the rest of the world), the International Treaty of the Meter, signed by over 51 countries today, puts the metric system as the International Standard (IS).

With rapid-moving globalization, an agreed-upon measurement system is crucial. Manufacturers sometimes have plants in multiple countries, so uniformity is key for regulating metrology quality control in manufacturing.

We’re here to provide you with more details.

Reach out today!

Understanding Metrology in Manufacturing and How It Ensures Quality

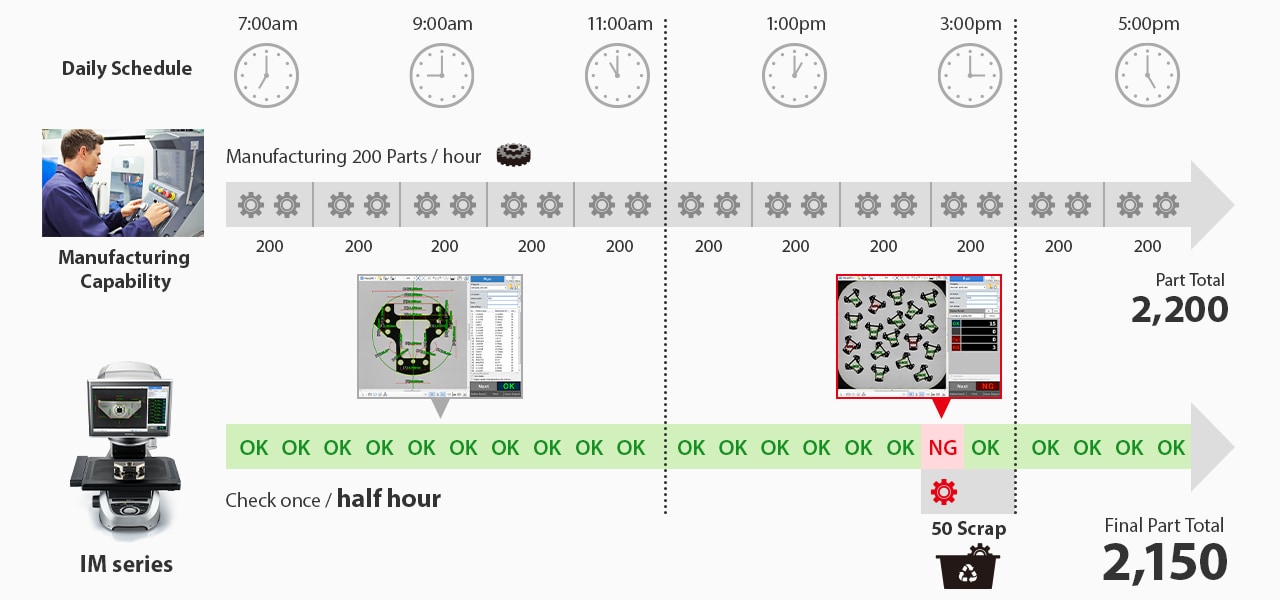

Statistical process control relies heavily on metrology equipment to detect variations before they become defects. Real-time monitoring systems track dimensional changes and alert operators when processes drift outside acceptable limits. This proactive approach prevents costly rework and maintains consistent product quality.

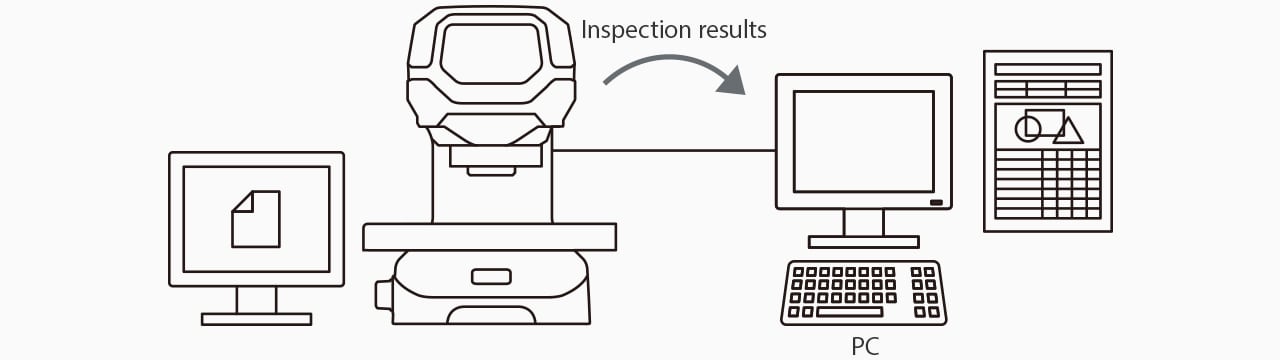

Quality certification programs require documented evidence of measurement capability and control. Industrial metrology systems generate detailed reports that demonstrate compliance with industry standards and regulations. 3D metrology data provides comprehensive documentation for audits and customer approvals, creating a complete quality record for each manufactured component.

How Are Metrology Tools Standardized?

The International Treaty of the Meter ensures that manufacturers use the same measurement system, but how do international standards ensure that tools produce correct outputs?

There are two ways: calibration and traceability standards.

Calibration

Calibration is defined as aligning a tool’s measurement with a standard reading. For example, putting a thermometer in boiling water to ensure that it will measure correctly. If the thermometer reads 20℉ for a boiling pot of water, you know there’s a problem with the thermometer.

Per the International Organization for Standardization (ISO), metrology tools must be calibrated before use to read accurate information. Manufacturers can receive calibration certificates to validate that their metrology tools follow the ISO calibration standards.

Traceability

Calibration is necessary for ensuring metrology tools work correctly, but traceability is needed for communication throughout manufacturing. In the case of metrology, traceability is the practice of sending data along the supply chain route so each manufacturer is up to date on a part’s history. This information is vital for quality control as it allows for quick recalls and uniform measurement across the manufacturing process.

Specific traceability regulations vary depending on the industry, but this generally means applying a mark or code that stores information like the calibration certificate, measurement data, the date the measurement took place, and manufacturing plant information.

Discover more about this product.

Click here to book your demo.

Optics-Based vs Contact Metrology Techniques

Vision-based systems represent a significant advancement in metrology equipment technology. These systems capture detailed images and process them to extract precise measurements without physical contact. Optical systems like Optical comparators offer rapid data collection across part surfaces in seconds.

Contact methods remain valuable for specific applications where tactile feedback is essential. CMMs with probes are most effective for inspecting internal features and hidden surfaces. Modern Multisensor Measurement Systems combine both contact and non-contact methods for maximum flexibility based on part requirements.

How Metrology Tools Maintain Accuracy

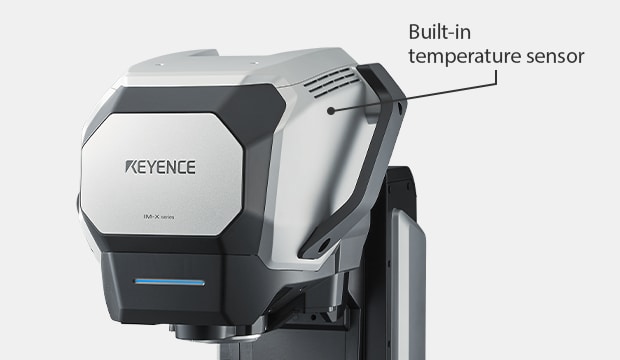

Maintaining precision in metrology equipment requires systematic approaches to minimize errors. Temperature compensation systems automatically adjust readings as environmental conditions change. Built-in sensors monitor ambient conditions and apply corrections to ensure consistent results regardless of shop floor variations.

Regular checks ensure metrology systems stay within specifications. Automated systems detect issues before they cause problems, while built-in standards continuously verify accuracy during production.

Key Differences and Use Cases

For various production situations, each strategy offers unique benefits. Contact methods provide precise point measurements and outstanding accuracy for hard materials. With programmable measurement sequences, advanced CMM equipment efficiently manages intricate inspection procedures.

Optical systems excel in high-volume production settings and with sensitive components. 3D measurement systems simultaneously capture millions of data points, enabling thorough profile measurements.

Common Challenges in Manufacturing Metrology

Metrology equipment is increasingly required to function faster without compromising accuracy. Since production schedules often conflict with the requirement for comprehensive inspections, there is pressure to reduce measuring times. Strategic planning and automated systems that can keep up with production needs are necessary to strike a balance between speed and precision.

Part complexity continues to grow as products become more sophisticated and miniaturized. Industrial metrology systems must handle increasingly tight tolerances on smaller features. Multi-material assemblies present unique challenges, as different expansion rates and surface properties necessitate specialized measurement approaches. Multisensor measurement tools address these complex requirements with advanced analytical capabilities.

What Affects Measurement?

Measuring perfectly isn’t an easy process. Inaccurate measurements can happen from ambient vibration, high or low temperatures, debris, part movement, technician changes, or basic human error.

Ambient vibration can shake the machine, and high or low temperatures can cause the part to expand or contract. Debris can block a lens or attach to a part. Using contact measurement tools can accidentally change the positioning of a part or affect its geometry. Changing technicians and human error are hardly avoidable with handheld machines.

All of these factors are almost entirely unavoidable on the shop floor; however, some provisions of metrology tools lessen the effects on the measurement.

Curious about our pricing?

Click here to find out more.

How Non-Contact Measurement Tools Revolutionize Quality Control

Integration with production lines enables continuous quality monitoring without disrupting workflow. 3D metrology systems can be embedded directly into manufacturing cells, providing immediate feedback on part quality. This integration allows for real-time process adjustments and prevents defective parts from progressing through subsequent operations.

Advanced data analytics transform measurement results into actionable insights for process improvement. Patterns in dimensional fluctuations that indicate emerging problems can be identified using machine learning techniques. By enabling preventative maintenance and process improvement, these predictive capabilities go beyond conventional reactive quality control methods.

How to Ensure Quality Control in Manufacturing With Metrology Tools

Being intentional about metrology tools is key for keeping your measurements as accurate as possible and complying with international calibration and traceability standards. At KEYENCE, we specialize in metrology tools that automate the measuring process to keep the highest standard and make the measuring process more manageable.

We offer four measurement device types with calibration and traceability data analysis software, feedback loops, non-contact and contact measurement options, and user-friendly software. Let’s explore each of these features and the machines they apply to.

Calibration and Traceability

As previously mentioned, calibration and traceability are necessities for establishing quality control. KEYENCE's image dimension measurement systems (IM-X Series) and coordinate measurement machines (XM Series and WM Series) all use vision-based measurement. This enables the systems to only need to be recertified annually, rather than recalibrated, saving time and money for users. This method for recertification follows international and national standards that align with the measurement machine.

Non-Contact

Most of KEYENCE’s metrology tools, except for the coordinate measurement machine probe, use non-contact methods for measurement. KEYENCE’s machines measure with the press of a button, so no human or tool comes in contact with the part.

Small or fragile parts can be placed on the stage and will resist any measurement errors from coming into contact with a device. Even more sensitive materials that deform or are easily contaminated (like food) can be measured by in-line sensors that do not require any stage.

Even the contact probe for KEYENCE’s CMMs still has a “wireless” aspect to it. The probe is completely untethered, allowing for easy in-machine measurement and portability to bring the measurement system wherever necessary.

Technician Changeover

KEYENCE's IM-X metrology tool is automated and has a telecentric lens and a high-precision camera that captures and measures a part the same way every time, regardless of the technician or part placement. KEYENCE XM and WM metrology tools have an easy-to-follow measurement procedure that any user can replicate, with parameters put in place to eliminate human error.

No Effect From Ambient Vibration or Temperature

KEYENCE’s IM-X and CMMs (XM Series, WM Series) have built-in temperature sensors that nullify the effects of the environment for the most accurate measurements. The CMMs are designed to be durable for use even in harsh environments like manufacturing sites. A high-accuracy sensor in the camera unit diagnoses whether ambient vibrations will adversely affect measurement. They also have a temperature compensation function that ensures measurement targets are measured under the same conditions, just like a climate-controlled measuring room, even if the ambient temperature is not constant.

Are You Ready for the Best Quality Control in Manufacturing Measurements?

Metrology is the foundation of manufacturing, making sure everything is consistent and adheres to standards. It’s an extremely important, strict and careful field that needs a lot of attention and rules to follow.

Whether ambient vibrations, technician changeovers, or the race to keep up-to-date data is holding you back, at KEYENCE, we have metrology tools that can streamline your measurement process. We pride ourselves on serving a global network of over 46 countries, which is why we are so keen on keeping up with international standards.

Contact us today to get more information about how metrology tools can improve your manufacturing processes.

FAQs

Are image-based systems reliable for transparent parts?

Yes, modern systems use specialized lighting and optics to accurately measure glass, clear plastics, and other transparent materials.

What is the learning curve for operating a vision CMM?

Basic operations can be learned in a few hours, while advanced programming requires additional training.

How is traceability ensured in digital metrology?

Digital systems automatically record all measurement data with timestamps and store it in secure databases for complete lifecycle tracking.

How does calibration impact the accuracy of measurement tools in manufacturing?

Proper calibration ensures accurate readings within specified tolerances and prevents measurement drift that can affect product quality.

How does automation enhance the effectiveness of metrology in manufacturing?

Automation reduces human error, increases speed, and provides consistent results with real-time feedback for process adjustments.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.