Measurement Sensors

Dimension Measurement

Displacement Measurement

How Precision Measurement Enhances Quality Control in Manufacturing

Precise measurements are vital to the production of durable products. Even the most minor deviations in manufacturing can lead to defects and safety concerns. Accurate laser displacement sensors and glass position sensors can avoid these flaws.

These tools also monitor the production process. They can detect even the slightest inconsistencies, which helps identify flaws. For example, a glass position sensor can pinpoint subtle shifts in alignment during assembly that would otherwise compromise a product’s longevity. Manufacturers can integrate these sensors into their operations to maintain quality product standards.

Integrating measurement tools into manufacturing workflows helps maintain quality standards and improve workflows for operators. These systems also help reduce errors and minimize rework, which can be pretty costly.

The Connection Between Measurement and Quality Control

Precision measurements are essential to every part of the manufacturing process and directly influence the quality of the end product. Operators must consistently measure and monitor key aspects of production in industries with tight tolerances.

Cost Savings

Precise measurements minimize material waste and unnecessary rework, which helps lower production costs. Efficient processes save time and boost manufacturer profitability.

Customer Satisfaction

High-quality and defect-free products foster customer trust and loyalty and protect the manufacturer's reputation.

Focusing on measurement and quality control improve processes and the manufacturers’ bottom line. New and returning customers will always go to manufacturers they can rely on, and that business will not go away once standards are consistently upheld. That is why measurement and quality control are so important.

We’re here to provide you with more details.

Reach out today!

Tools and Technologies for Accurate Measurement

Manufacturing precision measurements use advanced tools designed to deliver reliable and repeatable results. These technologies help ensure consistent quality and meet tight tolerances.

Throughout the production process, the product must be measured several times to make sure it complies with standards. Glass measurement sensors provide real-time data to operators, which allows them to catch the smallest of deviations. For example, a gradual change in thickness could indicate an issue with material feeding or calibration in earlier stages of production. Addressing anomalies early reduces waste and minimizes the risk of downstream defects.

Glass position sensors play an equally vital role during assembly. These sensors monitor the alignment of glass pieces and ensure each component fits perfectly in its intended application. For instance, even slight misalignment during the bonding process can compromise structural integrity in automotive glass production.

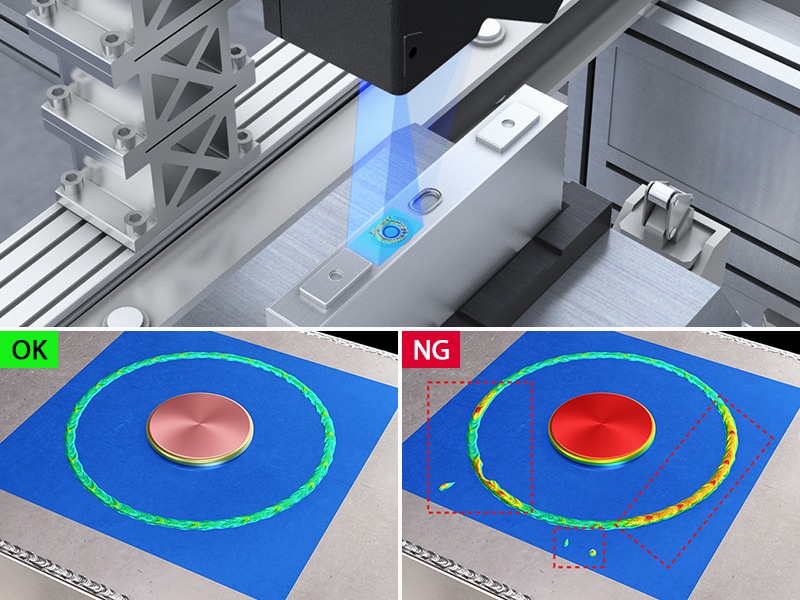

Inspection technologies offer another layer of quality control, especially for industries that need defect-free glass. High-resolution imaging systems combined with automated inspection tools can identify surface imperfections, structural flaws, or dimensional variances invisible to the human eye. These types of systems also process and analyze multiple parameters and factors, providing a comprehensive view of the product's condition in a single scan.

Coordinate Measuring Machines (CMMs) are often used for three-dimensional assessments. They are indispensable for verifying complex geometries and tight tolerances. The accuracy and speed of inspections carried out by CMMs are significantly improved by integrating non-contact measurement technology.

Vision systems and 3D Laser Snapshot Sensors further enhance accuracy and flexibility. Non-contact methods allow fragile components, such as thin glass panels, to be measured without risk of damage. These types of systems also process and analyze multiple parameters and factors, providing a comprehensive view of the product's condition in a single scan.

Integrating the above tools into an efficiency system can transform operational efficiency. An enhanced measurement system will improve early defect detection, real-time adjustments, and consistent monitoring. Similarly, an integrated system of advanced measurement tools will improve downtime, resource use, and the meeting of stringent industry standards.

We’re here to provide you with more details.

Reach out today!

Improving Manufacturing Efficiency with Precision

Precision measurement is more than a tool for maintaining quality—it’s a catalyst for manufacturing efficiency. By integrating accurate measurement systems into production processes, manufacturers can optimize workflows and reduce downtime.

Glass measurement sensors and glass position sensors help eliminate guesswork, which enables operators to make immediate adjustments when tolerances shift, or alignment issues arise.

Automation and precision measurement often go hand in hand, enhancing efficiency further. Automated inspection systems with advanced imaging or non-contact measurement technologies can analyze thousands of components per hour without compromising accuracy.

Precision measurement also plays a key role in resource optimization. For example, glass inspection technologies catch flaws early, reducing the need to discard entire batches.

Identifying potential issues early through precise monitoring also supports predictive maintenance. When measurement deviations are detected, operators can address equipment wear or calibration errors before they lead to costly downtime. The idea is to keep machines and equipment in the best condition possible to promote high throughput and fast production cycles. A proactive maintenance and inspection system is a great way to ensure everything continues running at optimal rates. This, in turn, will allow manufacturers and production lines to produce reliable products faster and with fewer resources.

Looking to upgrade your quality control processes? KEYENCE is here to help! Since 1974, we have been a global leader in factory automation and quality assurance equipment, specializing in technologies like measurement sensors and vision sensors for all industries.

If you’re ready to enhance precision and reduce downtime in your production line, contact KEYENCE to explore how our solutions can transform your operations. Achieve superior quality control and explore precision measurement with KEYENCE today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity