Measurement Sensors

Dimension Measurement

Displacement Measurement

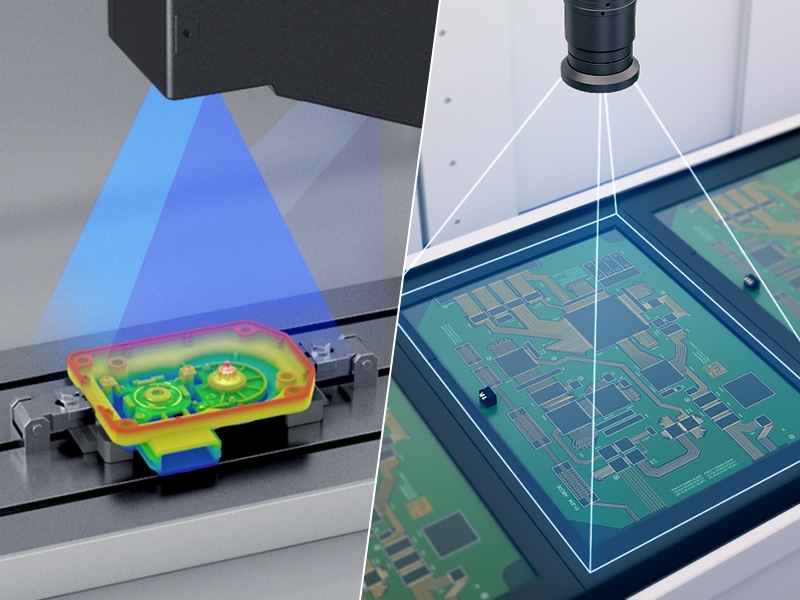

Laser Snapshot Sensors vs. Camera-Based Snapshot Sensors: Which Is Right for Your Application?

Both laser snapshot sensors and camera-based snapshot sensors can capture precise data for quality control, inspection, and metrology. However, it becomes pivotal to understand the key differences between both devices to apply them correctly. This article will serve as a guide.

What Are Laser Snapshot Sensors?

Laser snapshot sensors perform high-speed, high-accuracy 3D inspections on stationary targets. These sensors are self-contained, meaning no additional lighting/encoders/lenses are needed to capture a 3D image.

Laser snapshot sensors work by sweeping a laser line across an object’s surface. The sensor captures reflected light and uses it to reconstruct a 3D image. As a result, these sensors can measure width, height, area and volume.

We’re here to provide you with more details.

Reach out today!

What Are Camera-Based Snapshot Sensors?

Unlike laser snapshot sensors, camera-based sensors operate on a different principle. Instead of using lasers to produce an accurate 3D model, camera-based sensors rely on optical cameras and image processing algorithms to capture 2D images of objects. Some systems also use structured light or stereo vision to capture surface data and create 3D models.

Camera-based snapshot sensors are effectively machine vision systems. They apply more where things like image quality, color recognition, and 2D/3D object tracking are crucial. Their optical nature allows them to capture a broader field of view compared to laser sensors, making them suitable for inspecting large objects or capturing detailed visual information like color, texture, and markings.

The primary strength of camera-based snapshot sensors is their ability to process images with high clarity. For tasks such as barcode reading, object recognition, and visual inspection, camera-based snapshot sensors perform well.

Differences Between Laser Snapshot Sensors and Camera-Based Sensors

Here is a quick comparison between laser snapshot sensors and camera-based snapshot sensors. This will help you choose the right technology for your needs.

1. 3D Measurement

When it comes to measuring capabilities, laser sensors are usually the best. They are designed to measure the full 3D surface of an object with extreme precision, which is why they excel in capturing depth, height, and dimensional data. If your goal is to obtain accurate 3D measurements, laser sensors should be your choice. While camera-based sensors can also generate 3D models, they are better at capturing high-resolution 2D images. For any task focused on visual analysis alone, such as color recognition or pattern matching, camera-based sensors are more appropriate.

2. Single-Shot Measurement

If you need to capture the full 3D profile in a single shot, laser sensors are faster for such tasks. It is easy to use and saves time during high-speed inspections on production lines. As for the camera-based sensors, they can also process data quickly. Depending on the level of detail required and the complexity of the object, they may need more processing time. They are more efficient for 2D image processing than 3D scanning.

3. Complex Surfaces

Inspecting complex surfaces is no new territory for laser sensors. In fact, their precision here is always greater, even when it comes to surfaces with reflective, transparent, or shiny properties where camera-based sensors may struggle, as optical cameras work based on light reflection.

4. Environmental Factors

In environmental conditions with poor lighting or dust, laser sensors still work perfectly well, whereas camera-based sensors are more sensitive to these factors.

5. Field of View

Laser sensors have a narrower view compared to cameras, focusing more on precise data for specific areas. Cameras offer a wider field of view, making them ideal for capturing more/larger areas in a single frame.

6. Cost

Laser snapshot sensors are more expensive because of their accuracy and adaptability. Camera-based sensors may only be a cost-effective solution when you do not require high-precision 3D data.

Curious about our pricing?

Click here to find out more.

Performance Comparison: When to Use Each Technology

Choosing between laser snapshot sensors and camera-based snapshot sensors depends largely on where you will be applying it and the kind of image you want to get. Below is a performance comparison that highlights when each technology should be used.

Laser Snapshots

Laser sensors provide precise data on depth, height, and any kind of surface. They are ideal for inspections in high-speed production environments and capture 3D data quickly, making them perfect for inline quality control. If the industrial need demands precise 3D measurements or in-depth data, laser snapshot sensors are the best option.

Camera-Based Snapshot Sensors

If your primary goal is to inspect visual details such as color, texture, or patterns, camera-based sensors are preferable in tasks like barcode reading, label verification, and pattern recognition.

For industries that require capturing a large area in a single shot, they can inspect bigger objects and provide comprehensive 2D image data. If your environment allows for controlled lighting conditions, camera-based sensors can deliver excellent results in visual inspections.

Choosing Between Laser and Camera-Based Snapshot Sensors

When it comes to factory automation and quality assurance equipment, KEYENCE is your one-stop shop. We offer different technologies, including automation sensors, measuring sensors and instruments, vision systems, data acquisition systems, laser markers, and digital micros.

If you want to choose the right sensor technology, consider where you will apply it, understand the demands of your environment, and determine the type of data you need. The specific features of the objects you are inspecting will also play a big role in your choice. It is important to carefully consider these factors to improve your production processes and quality control while ensuring the best results for your specific industrial needs.

For more insights on how to choose the right sensor for your application, check out KEYENCE's guide to measurement sensors.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity