Measurement Sensors

Dimension Measurement

Displacement Measurement

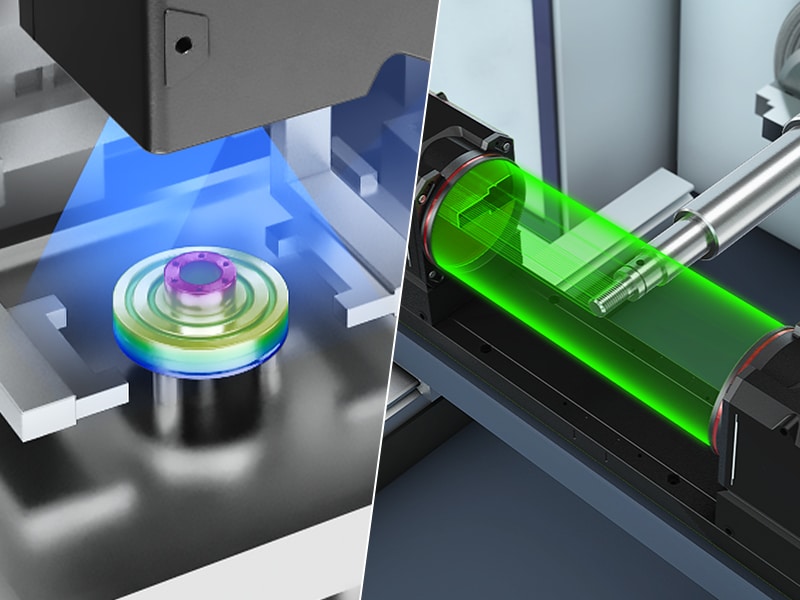

Laser vs Optical Measurement: Choosing the Right Solution

Industries worldwide rely on accurate and efficient systems to stay competitive. They also help products meet specifications, reduce waste, and help maintain consistency across work orders. Optical measurement systems offer production lines the ability to capture intricate details and analyze dimensions which help ensure consistent output. The transition from manual measurements to optical systems has allowed for faster inspections and improved operational efficiency. They also integrate into existing workflows with ease which makes optical systems a preferred choice in some industries.

On the other hand, laser-based measurement systems stand out for operations that require high-speed data acquisition and need to capture complex 3D profiles. Additionally, these systems are very effective in dynamic and evolving environments such as those in the construction, automotive, robotics industries.

Measurement systems, whether laser or optical, are important tools in industries with high standards and tight tolerances. These systems not only help manufacturers measure and inspect components with extreme accuracy, but they also streamline workflows and improve the quality of end products.

Understanding Laser Measurement: How It Works

Whether for quality control, assembly line optimization, or prototyping, laser measurement systems offer a bevy of solutions that traditional methods cannot match. These systems rely heavily on advanced optics and detectors, which makes them a great option for industries that face exceptional challenges with accuracy.

The fundamental principle of laser measurement is light reflection; lasers emit focused beams of light and analyze how those beams interact with a surface. A laser beam is directed toward an object and the system calculates how long it takes for the light to reflect back. This process is called a ‘time-of-flight’ measurement, and it allows for accurate distance calculations.

Lasers also use methods such as triangulation and phase-shift analysis to take a variety of other measurements. Laser systems are also a non-physical, non-contact measurement method. The beams of light can address delicate components without damaging them.

Modern laser systems are perfect in dynamic environments and are ideal for tracking objects moving on conveyor belts and processing large volumes of data; it is also incredibly useful in 3D mapping, surface profiling, and dimensional analysis. Lasers are incredibly useful at delivering precise and non-invasive measurements.

We’re here to provide you with more details.

Reach out today!

What Is Optical Measurement, and Why Use It?

Optical measurements utilize light-based systems to capture and analyze precise dimensions of objects without physical contact. This method relies on advanced optical components, including illumination systems, lenses, and sensors. These gather data about an object’s dimensions, surface features and even material properties. These systems have evolved significantly since the early 20th century manual methods as today’s systems are fully automated.

One of the defining features of optical measurement equipment is the ability to perform non-contact measurements. This capability is especially valuable for delicate or intricate components like thin plastics, fragile electronics, and precision-molded parts. Since the machinery avoids physical contact, these optical systems prevent damage to the material. This is particularly useful in industries like medical device manufacturing, as each component is incredibly delicate. It is similar for aerospace manufacturing in that traditional contact-based inspection methods fall short.

While non-contact is a very important feature, it is not the only one. Speed is also a critical factor in manufacturing. Modern devices have to be capable of processing multiple measurements mere seconds apart. Optical systems handle this demand with ease. This technology is also incredibly versatile and can handle a wide range of applications; from part inspection to measuring massive assemblies and everything in between.

Comparing Accuracy: Laser vs Optical Measurement Systems

The debate between laser-based and optical measurement systems often centers around one key feature: accuracy. Both of these technologies are exceptional in their respective domains, but understanding their distinctions can help manufacturers identify which is the ideal solution for their specific application.

Optical measurement systems excel in measuring delicate and/or intricate components. For example, in the medical device industry, minute deviations can compromise safety. With optical systems, these defects are detected before the device gets through the production line, which helps deliver consistent and reliable products. Optical systems are also very good in conditions with variable lighting and can take an accurate measurement even in a challenging environment. For small parts, the precision of an optical measurement system is unmatched.

Laser systems use laser beams to calculate distances and dimensions. Their strength lies in their long-range accuracy and their ability to capture detailed 3D profiles. They are also very effective in dynamic environments, with some lasers being able to take accurate measurements from 10 meters away. Another positive of laser systems is that they are less likely to be affected by external environmental factors such as dust or vibrations, which makes them well-suited for outdoor and industrial environments.

When comparing the two, the difference will really rely on the use-case. Optical measurement systems are the go-to for small components, and laser measurements systems shine in large-scale applications. Ultimately, choosing the right system will depend on what is being produced.

We’re here to provide you with more details.

Reach out today!

Applications Suited for Laser Measuring Instruments

For laser measurements, their ability to gather and process precise data over large areas and surfaces makes them an invaluable tool. For the construction and infrastructure industries, lasers make site surveys a breeze. Engineers use them to map out large areas, measure distances, and align beams and panels to ensure structural integrity. Laser systems are also easy to integrate into existing technology like Building Information Modeling (BIM).

In the automotive industry, laser measurement systems are heavily depended on for quality control and assembly. These instruments accurately measure components like curved body panels and engine parts. Lasers help reduce errors in production by aiding in chassis alignment and guiding wheel assembly.

For the robotics industry, laser measuring instruments are used in navigation, object detection, and motion control for autonomous systems by measuring the distance between the laser and an object. This gives the systems enough time to avoid the collision. For example, robotic arms can be equipped with laser scanners that can inspect and sort parts with minimal intervention.

In other industries, like aerospace, the stakes are incredibly high for accurate measurements. Laser instruments can measure large fuselage sections and verify the accuracy of wing assemblies. They are also used to detect defects on turbine blades. The laser's non-contact nature is very important in this industry, as many aircraft parts are made of delicate materials that could be damaged if touched.

The adaptability of laser systems ensures they can handle the most complex tasks without compromising on quality. For projects big and small, laser systems can handle it all.

Whether you’re optimizing your production lines or pushing the boundaries of precision in your industry, KEYENCE’s cutting-edge technology is here to elevate your operations. Since 1974, we have been a global leader in laser and optical measurement systems that are designed to fit any industry need. Our non-contact optical measurement systems and advanced laser measuring instruments can help you meet the most stringent demands.

Ready to transform your process and elevate your accuracy? Explore our wide range of offerings and learn how you can benefit from the KEYENCE difference.

Discover the best measurement solution for your application with KEYENCE – contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity