Measurement Sensors

Dimension Measurement

Displacement Measurement

The Role of 3D Measurement in Smart Factories

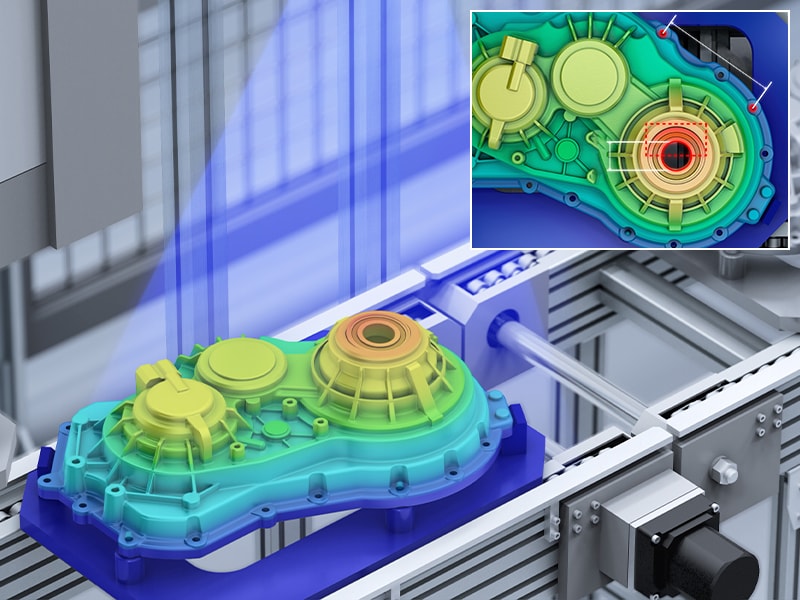

In smart factories where production relies on an advanced ecosystem, 3D measurements create a transformative and modern manufacturing environment. Smart factories use 3D measurement tools to help keep product quality in check, improve production speed, and reduce overall waste.

Traditional measurement methods often lead to errors, inefficiencies, and high costs. In contrast, 3D measurement tools offer real-time, in-line inspection to make sure that every component meets exact specifications before advancing through the production process.

The Growing Importance of 3D Measurement in Manufacturing

The evolution of 3D measurement technologies began in the 1960s with the introduction of coordinate measure machines (CMMs), which utilized touch probes for more exact metrology. By the 1970s and 1980s, laser-based 3D measurement systems emerged which gave production facilities the ability to operate at high speeds with a no-contact surface analysis. The 2000s saw the rise of AI-powered 3D measurement tools. These tools can now integrate directly into smart factory automation processes, providing real-time, in-line inspections."

With modern manufacturing demanding higher precision and faster production cycles, 3D measurement systems provide continuous feedback and automated quality control that helps eliminate bottlenecks caused by defects and rework. To help tackle these challenges, 3D measurement tools have become important in maintaining consistency and minimizing defects.

We’re here to provide you with more details.

Reach out today!

How 3D Measurement Enhances Efficiency and Accuracy

3D measurement systems enable real-time process control to help factories focus on speed and precision. These systems help eliminate human error by replacing manual inspections with AI-driven 3D measurement tools to maintain high standards and repeatable results. Using IoT-connected sensors, they also help detect dimensional deviations before defects occur.

As companies move away from mass production and toward high-mix, low-volume (HMLV) production models, many manufacturers need fast and flexible solutions that are highly adaptable to automation to handle the frequent product changes and highly specialized components. 3D measurement tools help eliminate the need for extensive recalibration, as well as the overwhelming task of manually inspecting small amounts of many products that have different specifications.

Efficiency gains are further realized through optimized material usage. 3D laser measuring devices make sure components adhere to exact material specifications; this reduces waste and prevents unnecessary rework. These tools also have the ability to handle the complex geometries of different products as 2D laser measuring equipment provides non-contact, high-precision measurements for intricate or delicate designs. An example of this is how these tools can maintain a step height measurement as advanced metrology systems detect variations in the layered materials and ensure each step meets tight tolerances.

Essential 3D Measurement Tools for Smart Factories

The success of smart factories depends on selecting the right 3D measurement tools. 3D measuring devices are among the most effective, offering high-speed, non-contact scanning for both small and large components by using Time-of-Flight (ToF) and triangulation-based scanning techniques. ToF technology measures the time it takes for a light pulse to travel to an object and back, while triangulation calculates the distance by measuring the angle of a projected light beam hitting the object relative to a camera position.

Another important technology used in smart factories is called structured light scanning. This projects a patterned light onto an object and analyzes deformations to generate a precise 3D model. This method is particularly helpful for measuring delicate materials such as glass or reflective metals that traditional tools tend to struggle with. This can be very useful when verifying the thickness and width of transparent surfaces. If a facility needs greater flexibility, optical metrology systems allow manufacturers the ability to conduct real-time, on-site inspections without having to rely on fixed setups.

Smart factories also benefit from advanced CMMs which are widely used for high-precision contact-based 3D measurement. Modern multi-sensor CMMs combine tactile probes with optical scanners to provide versatility in measuring both simple and complex geometries. To further complement these tools, AI-powered machine vision systems automate imaging and defect detection, which helps improve production accuracy and efficiency, reducing the reliance on manual inspections.

We’re here to provide you with more details.

Reach out today!

The Impact of 3D Measurement on Quality Control

Traditional quality control methods rely on post-production inspections which could lead to delays and wasted materials. Smart factories now include 3D measurement tools directly into their production lines to facilitate defect detection and correction.

Automation in-line inspection systems verify that parts are measured during manufacturing rather than after production is complete. 3D laser measuring devices capture precise dimensional data instantly, which prevents defects from passing through the entire production process. Additionally, machine vision technologies provide surface inspection and texture analysis which helps identify imperfections that could compromise product integrity.

Above all, these improvements support a closed-loop manufacturing system. This is where 3D measurement data is fed back into production automation to make adjustments in real time. Smart factories also utilize digital twins, which use 3D laser measuring equipment to create virtual models of physical components. Once created, these models can be changed or modified for a more efficient design or they can be used to simulate how the part will fit and function within the finished product.

Business Benefits of Integrating 3D Measurement Systems

By automating dimensional inspection, manufacturers can reduce their scrap and waste while also minimizing rework. Another benefit is how it leads to an accelerated production line and lowers cost.

3D laser measuring devices help reduce waste through real-time defect detection. This is especially valuable in high-precision industries like aerospace and semiconductors where materials are costly and the most minor errors can result in product failures.

Beyond efficiency, 3D measurement systems support regulatory compliance. Many industries have strict tolerances, like medical devices and defense manufacturing, that have to be met at all costs. Automated measurement systems help manufacturers comply with safety and quality standards where lives could be on the line.

Overcoming Challenges in 3D Measurement Implementation

Despite all its benefits, 3D measurement systems present their own challenges, including: cost, adoption, and data management. 3D laser measuring equipment requires significant capital investment, which may be an obstacle for some. However, the long-term savings from reduced waste and fewer defects justify the expense. Many manufacturers benefit from a phased approach which implements key measurement systems first before scaling factory-wide.

Combining an existing workflow with a new system can be complex. Many factories use legacy equipment, which makes it difficult to synchronize real-time 3D data with manufacturing execution systems. IoT-enabled 3D measurement tools help solve this by feeding data into production control systems, which provides measurement insights directly to operators.

3D scans and laser-based inspections generate massive datasets which can be difficult for older systems to analyze efficiently. Cloud-based platforms can help process this data and use analytics to help manufacturers convert raw data into actionable insights.

Many factories may struggle with workforce adaptation. Thankfully, many of these systems eliminate the minutiae that operators face on a day-to-day basis and provide an opportunity for upskilling to maintain the new system.

Interested in upgrading your facility with a 3D measurement system? KEYENCE is here to help. Tools like Tools like 1D lasers and 2D lasers provide high-speed, accurate inspections, reducing defects and optimizing production. Whether you’ve worked with systems before or if you’re brand-new to this technology, give us a call today to explore our options.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity