Electrostatic Sensors

A static electricity sensor that accurately measures electrostatic charge to identify and diagnose locations with static build-up. A hand-held type—which can measure nearly anywhere—and an in-line type—which can measure the electrostatic charge of targets on a manufacturing line—are available.

Product Lineup

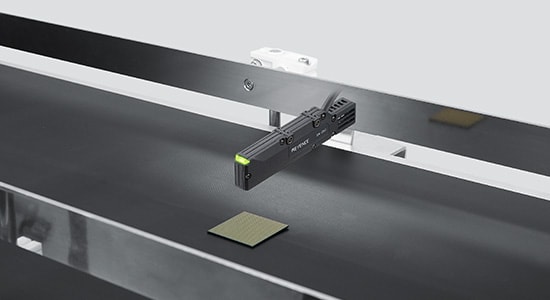

The major advantage of inline electrostatic sensors is that they can be installed in manufacturing lines, allowing for continuous real-time measurement of the electrostatic charge of targets. Conventional temporary measurement cannot detect problems caused by static electricity. One such example of these problems is a decrease in yield rate. However, real-time monitoring makes it possible to prevent these problems, contributing to improved manufacturing efficiency. This sensor can also improve quality management and traceability using measurement data, allowing it to respond to the advanced needs of manufacturing sites. Continuous monitoring and high-accuracy measurement made possible by inline installation help improve reliability at manufacturing sites that use cutting edge technology.

Features

Reasons Why Real-Time Monitoring of Target Electrostatic Charge is Required

Entry-level hand-held types are often chosen as the first tool for quantifying static electricity. Although capturing general trend values is possible with these sensors, monitoring conditions such as high-speed moving targets, environmental changes between morning and evening, or abnormalities during setup changes is more difficult. Even if inspections during equipment installation or maintenance pass, there are an increasing number of cases where yield issues—likely caused by static electricity—do not improve. Real-time measurement can dramatically enhance manufacturing efficiency for advanced devices.

Before

General trend value management with a hand-held measuring instrument

After

Continuous measurement with an inline measuring instrument

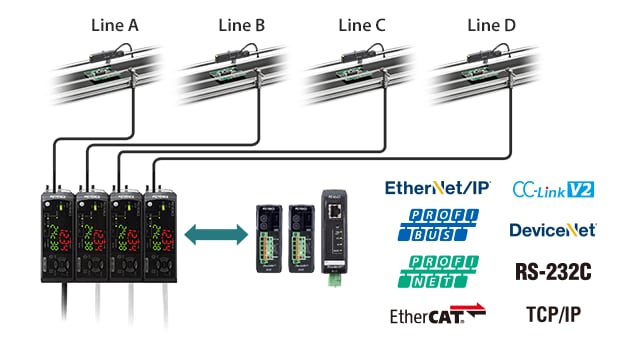

Easily Provides Visibility of Collected Data on Various Communication Networks

Standard specifications include an independent 3-output judgment system and analog voltage/current output to collect and output the static electricity volume of the target as well as the temperature and humidity data of the surrounding area. By using a communication unit, data from up to 8 connected main units and expansion units can be transmitted simultaneously. The ability to read data and re-write settings from PCs and PLCs contributes to a significant reduction in man-hours required for setup and operation.

KEYENCE’s hand-held type electrostatic sensor is widely used as an entry-level model for quantifying electrical charges of static electricity. It can also measure temperature and humidity, making it possible to comprehensively understand the relationship between environmental conditions and static electricity. In addition, it can evaluate the static elimination performance, such as speed and ion balance, of ionizers. In this way, this sensor promotes the effective operation and maintenance of ionizers while also helping prevent static electricity problems. This hand-held sensor allows for flexible measurement in any location, giving it the major advantage of supporting diverse needs in on-site applications.

Features

STATIC ELECTRICITY + HUMIDITY Simultaneous Measurement

Measuring static electricity and humidity simultaneously makes it possible identify likely areas of static-related problems, paving the way for optimal static electricity solutions.

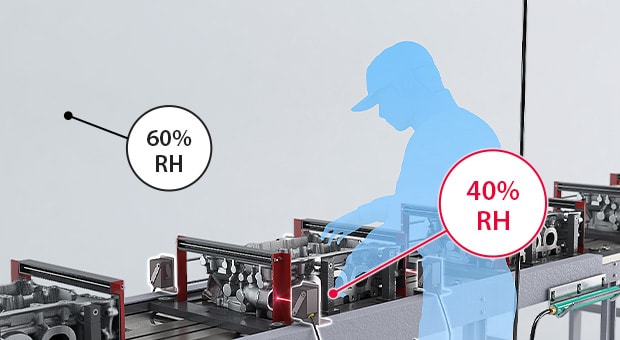

In addition, the humidity in the "area around the equipment" may be lower than that at the "room edge" because of the higher temperature. If static electricity problems persist despite humidity control throughout the room, checking the humidity "around the equipment" may help to resolve the problem.

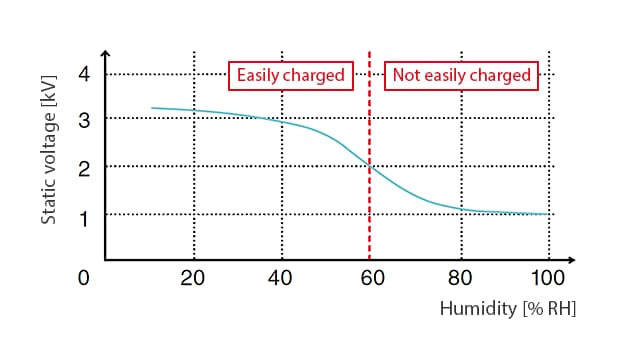

Relationship between humidity and static charge (typical example)

Example of different humidity between the edge of a room and near the equipment

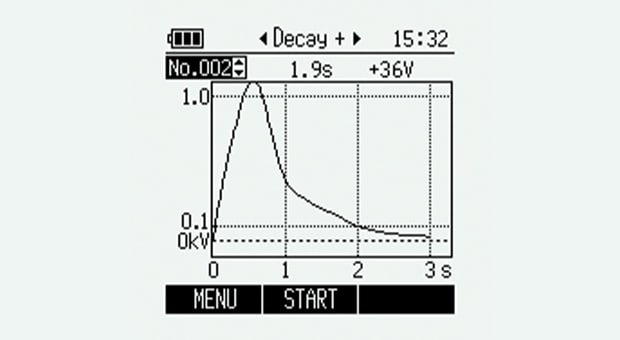

Determines the Static Elimination Performance and Deterioration Over Time of an Ionizer

The SK-H050 features a charge monitor function that measures static elimination speed and balance, both of which indicate an ionizer's static elimination ability.

* Required ionizer monitoring unit SK-H055 sold separately.

An electrostatic sensor measures the static electricity present in a given area, detecting the electrostatic charge created when an object attracts or repels nearby particles. KEYENCE’s sensors are designed to measure both the static charge and environmental factors like humidity, providing an all-in-one solution for static control.

Electrostatic sensor measurement principle

A sensing electrode in the electrostatic sensor is used to measure the electric field intensity of a charged target, which generates an inductive charge in the sensing electrode. This inductive charge creates a current that is converted into an AC voltage signal and the charged potential is then detected from this signal.

Measured values become smaller as the electrostatic sensor moves farther away from the target and larger as the sensor moves closer (distance-dependent measurement). Accurate measurement is possible if the target is larger than the detecting range, but if the target is smaller, the measured value is less than it actually is (target size-dependent measurement).

KEYENCE’s SK-050/1000 Series electrostatic sensors feature a distance correction function that automatically compensates for distance-related errors. Users can easily prevent measurement errors by entering the installation distance into the amplifier.

Benefits of Electrostatic Sensors

Static electricity intensity can vary depending on the location, even within the same room. Individual parts can also have different charges. With a hand-held type static electricity sensor, pinpoint measurement is possible wherever accurate measurement of the static electricity amount is needed.

Even in a static-free room, parts can become charged through friction, peeling, or contact during assembly. Static electricity causes dust and particles to become attracted to and adhere to charged parts. If dirt adheres to parts sent to the next process, that dirt can end up inside the product.

Hand-held types can also be used to measure the amount of static electricity in an assembled part. If the charge exceeds the allowable amount, the part will be prone to dust and dirt. Static eliminators (ionizers) or other devices must then be used to eliminate static electricity. In this way, hand-held electrostatic sensors can be used to prevent adhesion of dust, dirt, and other contaminants.

To ensure effective countermeasures against static electricity in a production line, accurate measurement of static electricity generated at various locations through friction, peeling, and contact is necessary. Such conditions for static electricity generation can occur at various points in the manufacturing process, and using multiple electrostatic sensors enables measurement of static electricity in multiple locations.

By installing a large number of electrostatic sensors on the production line for measurement of generated static electricity at various locations, users can utilize both accurate control of static eliminators (ionizers) and accurate detection of the effects of static elimination. Continued measurement of static electricity and analysis of the accumulated data also make it possible to understand how static electricity amounts change due to changes in humidity and identify new areas where static electricity countermeasures are needed.

In other words, measuring static electricity at multiple locations along the production line allows users to prevent problems caused by static electricity in addition to checking the effectiveness of static eliminators and the status of current static electricity countermeasures.

There is an obvious close relationship between humidity and static electricity, but defining that relationship is difficult. Accurately determining this relationship is possible, however, with an electrostatic sensor capable of measuring humidity and static electricity at the same time.

Static electricity generation is less likely to occur if the relative humidity is 60% or more. However, because humidity changes as the temperature changes, the humidity may differ from place to place even in the same room. For example, the temperature around manufacturing equipment tends to be relatively high with low humidity. This means it is important to maintain an appropriate humidity where the measurement target is located rather than measuring the entire production area.

Using an electrostatic sensor to measure static electricity and humidity at the same time allows users to determine whether an area is likely to cause static electricity problems due to dry air. The data measured by the sensor can then be used to determine the most appropriate countermeasures against static electricity, such as by preventing targets from becoming charged or eliminating static electricity using a static eliminator (ionizer).

KEYENCE’s electrostatic sensors are designed with several features to deliver precise static control:

・Dual Measurement Capabilities: These sensors can measure both static charge and humidity at the same time. They provide an understanding of how environmental conditions affect static electricity.

・High Precision: With measurement ranges up to ±50 kV, the sensors offer accurate readings, supporting reliable data for static control. Paired with the ionizer SJ-L Series, which visually verifies that static has been eliminated, these sensors create seamless static management.

・Flexible Usage: Manufacturers can choose from hand-held models like the SK-H050 for on-the-spot measurements or in-line models like the SK-050/1000 for continuous monitoring on the production line. For more specialized needs, the ionizer SJ-M Series can be integrated with the sensors for focused static elimination in narrow spaces or over larger production areas.

・Ease of Use: Hand-held models are ergonomically designed for comfortable operation, while the in-line models are easily adapted into automated systems.

Electrostatic Sensor Case Studies

Food and medicine industries

A major static electricity problem that must be addressed in the food and medicine industries is “popping.” For example, when conveying tablets in a parts feeder, the guide rails can become charged through friction. If these tablets and a charged film repel each other, the tablets can pop out of their pockets. Such problems cannot be prevented using a vision system or other vision sensors, and any time a problem occurs, the production line must be stopped or the defective products must be removed, reducing the operating ratio.

Such problems can be prevented, however, by using an SK-050/1000 Series inline electrostatic sensor to measure static electricity during conveyance with parts feeders or other equipment. A static eliminator (ionizer) can then be used to remove static electricity if the measured values reach the upper limit.

Electrical equipment industry

Damage caused by electrostatic discharge (ESD) is a major concern in the electrical equipment industry. For example, if a worker (grounded with a wrist strap) lifts a PCB that has been sprayed with PCB cleaner during cell processing, electric discharge may occur between the worker and the PCB, causing damage to the mounted IC components. This is because the PCB became charged when sprayed with the PCB cleaner. Although grounding is a common countermeasure against static discharge, grounding has no effect on insulators.

To prevent discharge in such cases, the static electricity on the PCB can be measured using an SK-H Series hand-held electrostatic sensor, and if the components are charged, the charge can be removed using a static eliminator (ionizer). This makes it possible to increase the effectiveness of anti-static measures during cell processing and to improve yield rates.

Automotive industry

A major static electricity problem in the automotive industry is the adherence of dust and dirt. Automobile bumpers become electrically charged after molding, resulting in dust and other dirt adhering to the components while being transferred to the coating process. Static electricity causes these foreign particles to strongly adhere to the products, and an external force is required to remove them. Even particles removed with an air blower will become reattached. If the particles are not removed properly before paint is applied, the surface will become uneven or irregular.

To prevent this, the SK-050/1000 Series inline electrostatic sensor can be used to measure static electricity on the bumper after molding, and if the measured value exceeds the upper limit, a static eliminator (ionizer) can then be used to remove the static electricity. This will prevent dust and dirt from reattaching even after removal with an air blower. This will also prevent paint from becoming uneven due to static electricity.

Static electricity can seriously impact production quality and safety. It can cause damage to sensitive components in automotive or electronics manufacturing through electrostatic discharge (ESD).

Static charges also attract dust and particles that stick to products and contaminate surfaces like printed circuit boards (PCB) or pharmaceuticals. This is known as Electrostatic Attraction (ESA).

KEYENCE electrostatic sensors detect static charge on surfaces and automatically adjust for distance-related errors, offering compensation for varying target distances.

These sensors also measure ambient humidity. Humidity directly affects static build-up, making both static charge and humidity measurements key for effective static control.

Electrostatic monitors like KEYENCE’s sensors continuously track static charge and humidity, preventing static-related issues and maintaining product quality overall. They are very important in industries like electronics, where they protect sensitive components, and in automotive, to prevent dust, dirt, and debris from clinging to surfaces, which compromises finishes.

In electronics manufacturing, electrostatic discharge can cause significant damage to PCBs and other sensitive components. To prevent damage, electrostatic detectors monitor static levels and prevent ESD events.

For the automotive industry, static charge can cause dust and dirt to adhere to parts like bumpers, affecting the quality of paint finishes. Electrostatic sensors measure static on parts and activate ionizers when necessary to prevent issues.

Static charge can cause issues in pharmaceuticals during the conveyance of tablets in parts feeders. By using electrostatic sensors, manufacturers can measure static levels and deploy ionizers to eliminate static.

Static electricity can also cause problems during packaging, especially when dust and particles cling to products. Electrostatic sensors help keep static levels controlled, which prevents contamination.

Static electricity problems can differ in nature depending on the industry or process. We introduce typical static electricity problems in different industries and processes, along with some actual cases of improvement made by introducing ionizers.

Ensure precise electrostatic meter measurements with KEYENCE’s electrostatic meters and field sensors today!

Frequently Asked Questions About Electrostatic Sensors

Static electricity can lead to various problems, including adhesion of dust and other foreign particles, conveyance problems, electrostatic discharge (ESD) damage, malfunctions in electronic devices and equipment, and coating/printing problems. Adhesion of foreign particles, for example, can result in defective products. Meanwhile, conveyance problems can lead to packaging defects and lower operating rates due to temporary stops, and electrostatic discharge can result in decreased yields or increased costs due to damage to electronic components.

Electrostatic sensors installed at locations where static electricity is generated can help prevent such problems through constant measurement of the static electricity in addition to static eliminators (ionizers) to eliminate any generated static. Electrostatic sensors can also be used for pinpoint measurement of parts and equipment off the production line, with static eliminators being used to efficiently control static electricity.

Electrostatic induction occurs in a conductor placed near electrically charged substances (dust or other foreign particles), causing the surface of the conductor to become electrically charged. This electrostatic induction and the static electricity of the foreign particles will create a force (Coulomb force) that causes them to adhere to other objects. The adhesion strength will vary depending on whether the object is a conductor or an insulator.

For example, the Coulomb force in insulators with a large surface area to mass ratio, such as films and sheet materials, is much greater than the weight of the object. The static electricity magnitude also varies greatly with humidity. Thus, to prevent adhesion of foreign particles due to static electricity, measuring both humidity and static electricity is essential.

Electrostatic discharge (ESD) results in damage when a charged electronic component comes into contact with a grounded conductor. As the charged electronic component comes into contact with the grounded conductor, a current is suddenly applied to the circuitry inside the component. This current causes the circuit wiring inside the component to melt, resulting in a short circuit or a break in the circuit.

Electrostatic discharge failures can be caused in a variety of ways, including discharges from workers with a static electricity charge (human-body model), discharges from metallic or conductive objects (machine model), and discharges by the device itself (charged-device model). Measurement of the static electricity of the source objects is necessary to prevent problems caused by these models.

This guide introduces basic knowledge in detail about static electricity, including how it occurs, different problems caused by static electricity, and how to prevent them. A must-read for anyone who is starting to implement real countermeasures against static electricity.

This document introduces actual examples of anti-static measures taken in the automotive, metal, electronic parts, food, and other industries. A must-read for people working with static electricity problems.

Particle adhesion problems are seen across industries such as semiconductors, LCDs, food and drugs, and automotive. This introduces everything from how particle adhesions occur to how to prevent them, how to remove dust after particle adhesion, and the latest static eliminators.