Optical Comparator (Profile Projector)

Photochemical Etching: Precision Fabrication for Flat, High-Volume Parts

Complex flat components with sensitive details are difficult for traditional manufacturing to produce. This issue is resolved by photochemical etching, which uses regulated chemical solutions to remove undesirable material without the use of heat or mechanical forces that could harm components. This process creates design opportunities that would be expensive or difficult to accomplish using some machining techniques.

Companies have discovered that chemical etching delivers exceptional results for parts requiring tight tolerances and clean edges. Electronics manufacturers, aerospace companies, and medical device producers rely on this technique to create everything from lead frames to decorative panels.

We’re here to provide you with more details.

Reach out today!

The Benefits of Photochemical Etching in Manufacturing

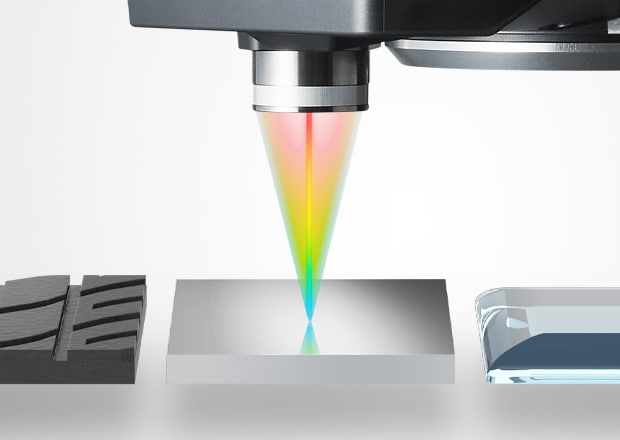

Chemical etching preserves the original material qualities throughout the part by removing material uniformly without causing stress or heat damage. In contrast to laser cutting or stamping, the chemical technique prevents dimensional fluctuations and performs equally effectively on thick and thin pieces.

Burr-free edges represent another significant advantage since the chemical process dissolves material rather than cutting or shearing it. This eliminates secondary deburring operations that add time and cost to production. Photochemical machining also excels at creating complex internal features like slots, holes, and intricate patterns that would often require multiple setups or specialized tooling.

Lead times drop significantly since creating new photomasks takes days rather than weeks, allowing rapid prototyping and design changes with minimal tooling requirements.

Why IM-X Systems are Perfect for Etching

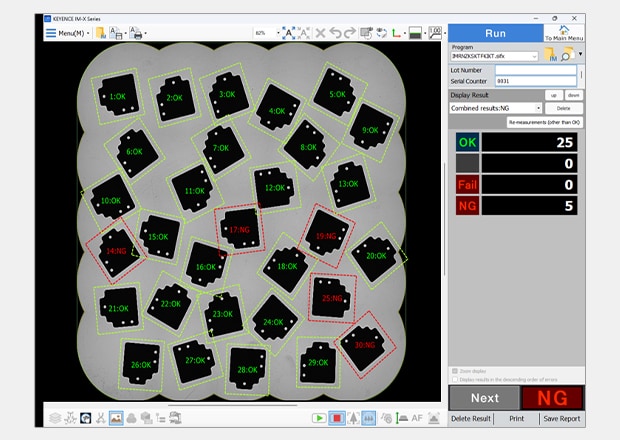

Quality checking for etched parts requires systems that can handle their unique characteristics. IM-X Series systems provide the precision needed to inspect these delicate components effectively.

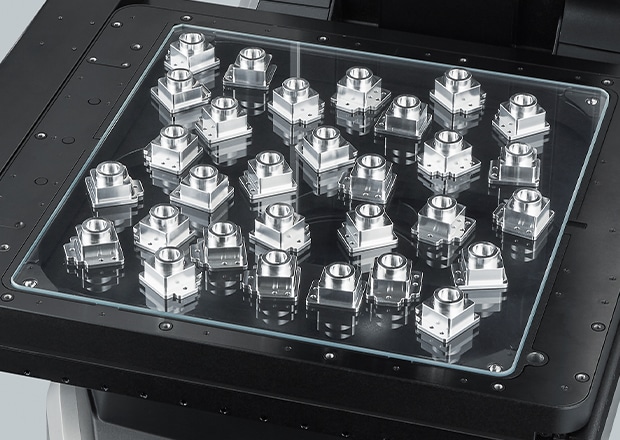

Manufacturers can choose different stage sizes and camera heads to match their specific etching inspection needs. The system is able to measure up to 1000 parts at once with just the push of a button, allowing for high-volume inspection with ease. Additionally, when initially setting up a program, the system automatically adjusts lighting and focus, making setup faster while giving consistent results even when etched parts have different surface textures.

Get detailed information on our products by downloading our catalog.

View Catalog

Scaling Up: High-Volume Production with Photochemical Etching

Because chemical etching is scalable, it benefits volume production. Multiple parts can be processed simultaneously on large panels, with hundreds or even thousands of components produced in a single etching cycle. This parallel processing capability makes the photochemical etching process extremely cost-effective for large quantities.

Consistency across high-volume runs depends on tight process control and regular quality verification. Measurement systems play a vital role in maintaining standards by quickly identifying any drift in dimensions or feature quality. Fast, automated inspection keeps production lines moving while catching potential issues before they affect entire batches.

Setup times remain minimal even when switching between different part designs. Changing photomasks takes minutes rather than hours, allowing facilities to run mixed production efficiently.

How Photochemical Etching Enhances 2D Part Fabrication

Flat components with complex geometries are ideal for chemical etching applications. Photochemical machining creates intricate patterns and features down to a few microns while maintaining excellent dimensional accuracy.

Chemical etching creates smooth, straight walls without cracks or heat damage, so parts don't need extra finishing work. Parts can be arranged efficiently on panels to use more material and reduce waste while keeping each part intact.

Discover more about this product.

Click here to book your demo.

Materials Suitable for Photo Etching

During etching, different metals work better with specific chemical formulations. Stainless steel brings corrosion resistance needed for aerospace and medical parts, while copper's conductivity suits electronic applications and maintains good dimensional control throughout processing.

Specialty materials like Inconel, titanium, and spring steels can also be etched, though they often need adjusted chemistry or longer processing cycles. Most applications work best with materials between 0.025 mm and 2.5 mm thick, depending on the alloy and feature complexity.

Why Choose Photo Chemical Etching?

Cost effectiveness becomes apparent when comparing total manufacturing expenses rather than just direct processing costs. Eliminated tooling costs, reduced setup times, and minimal secondary operations often make chemical etching more economical than alternatives, especially for complex parts or moderate volumes.

Design freedom allows engineers to create parts that would be impossible or prohibitively expensive using conventional methods. Features like varying slot widths, complex internal geometries, and arrays of precisely positioned elements become straightforward to manufacture.

Quality consistency improves because the chemical process doesn't suffer from tool wear or mechanical variations that affect other manufacturing methods. Each part receives identical processing, resulting in uniform dimensions and characteristics across entire production runs.

Get started with photochemical etching and streamline your production.

FAQs

What are the advantages of using the IM-X for photochemical etching?

The IM-X system offers modular design flexibility to match specific etching inspection needs, automatic programming that handles varying surface characteristics common in etched parts, and drawing import capabilities that work directly with photomask design files.

How does photochemical etching contribute to faster production cycles?

Chemical etching processes multiple parts simultaneously, requires minimal tooling changes between designs, eliminates secondary deburring operations, and produces parts ready for immediate use, significantly reducing overall manufacturing lead times.

What types of materials are ideal for photochemical etching?

Copper, brass, aluminum, stainless steel, and specialty alloys work well for photochemical etching within the 0.025 mm to 2.5 mm thickness range.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us