Optical Comparator (Profile Projector)

Non-Contact Inspection for Lithium-Ion Battery Cells

Battery production is growing rapidly as the popularity of electric vehicles continues to increase. Battery inspection helps deliver safe and reliable energy storage systems for these vehicles.

Lithium-ion cells must meet precise dimensions during manufacturing. Even small changes in cell shape can affect performance and safety. Contact measurement tools risk damaging soft battery parts, but non-contact measurement systems eliminate this issue while providing detailed quality data.

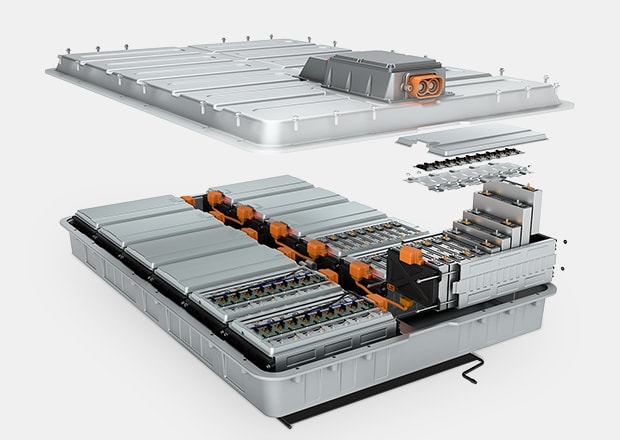

Battery production involves several steps requiring dimensional checks. Cell formation processes can cause swelling that changes dimensions. Assembly operations require parts to fit together perfectly to avoid performance issues and to meet strict safety requirements.

We’re here to provide you with more details.

Reach out today!

Why Dimensional Accuracy Matters in Battery Production

Battery cells operate under demanding conditions with high energy densities. Dimensional variations can create stress concentrations that lead to premature failure. Thermal expansion during charging and discharging cycles amplifies the effects of geometric irregularities.

Lithium-ion battery QC prevents safety hazards and performance problems. Proper electrode spacing in battery manufacturing metrology maintains electrical performance, while consistent wall thickness prevents dangerous hotspots. Accurate terminal positioning allows reliable connections. This creates gaps that reduce the effectiveness of thermal management. Dimensional control at the cell level prevents costly pack-level rejections.

Quality systems must detect problems before cells reach assembly operations. Early detection allows quick process fixes that reduce waste. Detailed measurement data helps identify the root causes of size variations and drive manufacturing improvements.

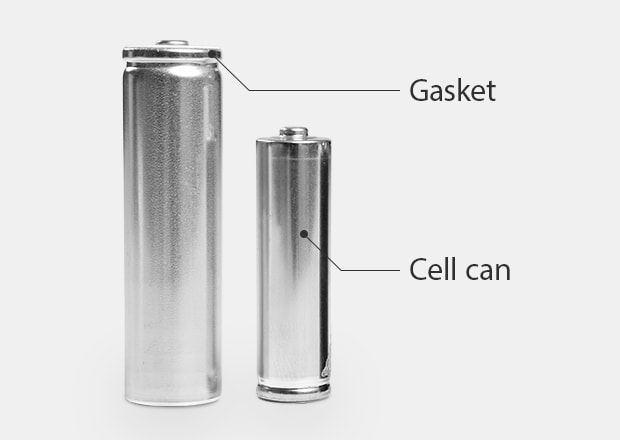

Cylindrical type

Common Battery Cell Types and Challenges

Pouch cells use flexible aluminum laminate packaging that can deform during handling. The soft materials require gentle measurement approaches. Formation swelling creates size changes that need tracking, while surface wrinkles make measurement more complex.

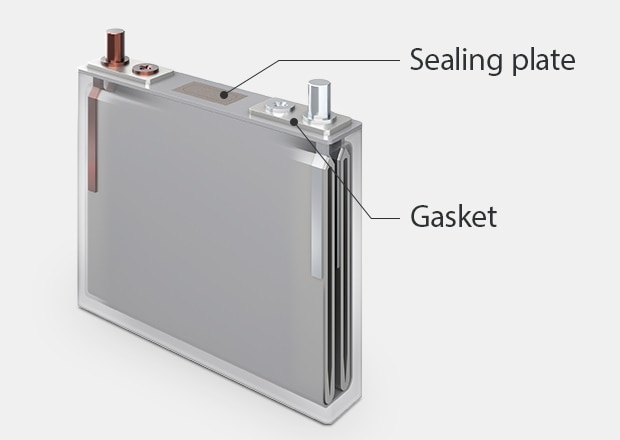

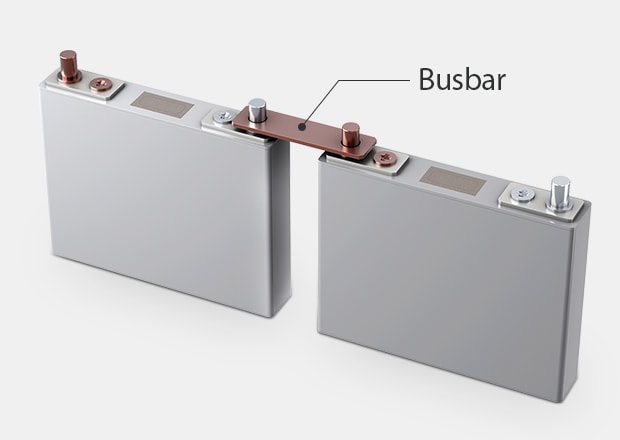

Prismatic cells have rigid metal housings with exact rectangular shapes. These designs need accurate edge and corner measurements, plus welded seam verification. Dimensional stability is better than pouch cells, but still requires careful monitoring.

Cylindrical cells offer the most dimensional stability due to their robust construction. However, they present unique measurement challenges for curved surfaces. Cap assembly requires precise alignment with cell bodies. Terminal positioning affects electrical connections in battery packs.

Battery cell dimensional inspection must accommodate these varied geometries. Each cell type requires different measurement strategies and fixturing approaches. Flexible inspection systems adapt to multiple formats without extensive reconfiguration.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Key Dimensional Features to Inspect

Cell thickness measurements check electrode compression and electrolyte distribution. Too much thickness means swelling or contamination, while too little suggests formation problems. Consistent thickness across the cell shows uniform manufacturing.

Length and width measurements check cell envelope size. These dimensions directly affect how cells fit in battery packs. Size variations can create stress during assembly and interfere with cooling systems and electrical connections.

Terminal locations have to match pack connecting systems precisely. Minor adjustments may result in poor electrical contact or assembly issues. Metrology techniques used in battery manufacture verify the shape and placement of the terminal to avoid problems with connectivity.

Surface flatness affects thermal management in battery packs. Warped cells create air gaps that reduce heat transfer. Dimensional analysis identifies problem cells and helps optimize pack designs.

Laminated, Prismatic, and Cylindrical Cells

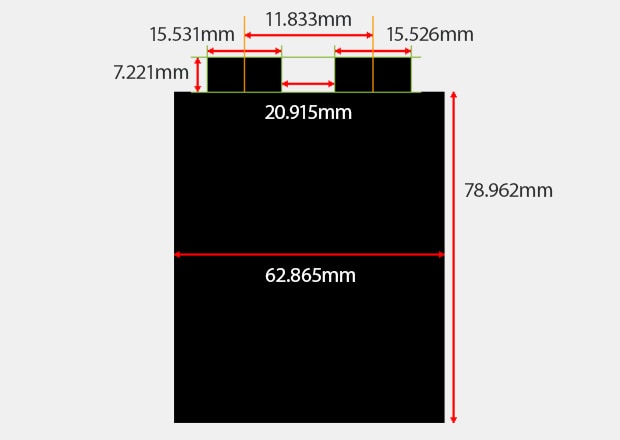

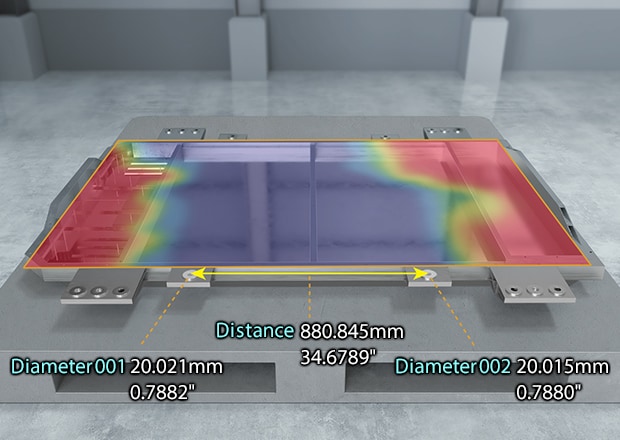

Laminated pouch cells require specialized handling during measurement. After lamination, the outer dimensions and the positions of positive and negative electrodes are measured. Positive and negative electrodes in incorrect positions may short-circuit, failing to ensure safety. They also may fail to charge and discharge as expected. As a crucial measurement item, their positions are commonly subject to offline sampling inspection in addition to 100% inline inspection. Many items need measurement, making the IM-X Series effective as it can measure multiple measurement points instantaneously.

Dimensional measurement of laminated packages [Laminated type]

Comprehensive coordinate measurement capabilities are advantageous for prismatic cells. In a single adaptable system, the WM Series CMM offers both contact and optical measurement possibilities.

There are particular difficulties in measuring the surface of cylindrical cells. The IM-X Instant Measurement System maintains excellent accuracy even with a variety of part shapes and materials.

Prismatic type

Different cell formats may require multiple measurement approaches on a single production line. Flexible inspection systems adapt to various shapes without major reconfiguration, reducing equipment costs while maintaining measurement capabilities.

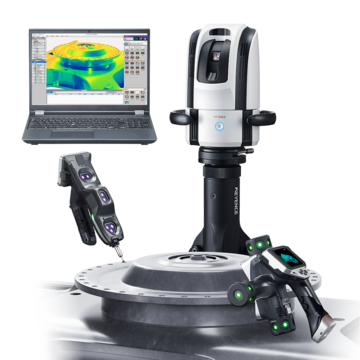

Battery Component Measurement (IM-X Series)

Electric vehicle battery production requires precise dimensional control of smaller components like cell housings, connectors, and cooling plates. Many measurement methods struggle to maintain accuracy while keep pace with production demands.

The LMX and IM-X Series excels at high-volume inspection of these smaller battery components. Rapid measurement cycles integrate seamlessly with production lines, while automated routines ensure consistent quality control without the issue of bottlenecks.

Cooling channel verification requires detailed internal geometry measurement. Proper flow characteristics depend on precise channel dimensions and geometries. Dimensional analysis aids in cooling system design optimization by identifying manufacturing variances that may impact thermal performance.

Component attachment points and structural interfaces need to line up precisely. Minor dimensional variations may result in assembly issues or compromise performance. Thorough measuring confirms important dimensions across smaller battery components.

Get detailed information on our products by downloading our catalog.

View Catalog

Automation and Traceability Integration

High-volume battery production requires automated inspection systems. The KEYENCE Instant Measurement Series Lineup offers a variety of automated capabilities in one system, integrating seamlessly with your manufacturing process. The speed and ease of these systems help reduce labor costs while improving measurement consistency.

Quality data management systems track individual cell performance throughout manufacturing. Statistical analysis identifies process trends before they affect product quality. Real-time feedback enables immediate process corrections that minimize defective production.

Traceability requirements in automotive applications demand detailed measurement records. All KEYENCE Metrology Systems offer automated inspection reports that can be used in real-time to apply corrections. Integration with manufacturing execution systems creates detailed production records for each battery component while enabling immediate process adjustments.

Contact us for a demo or to ask our specialists other battery inspection questions!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.