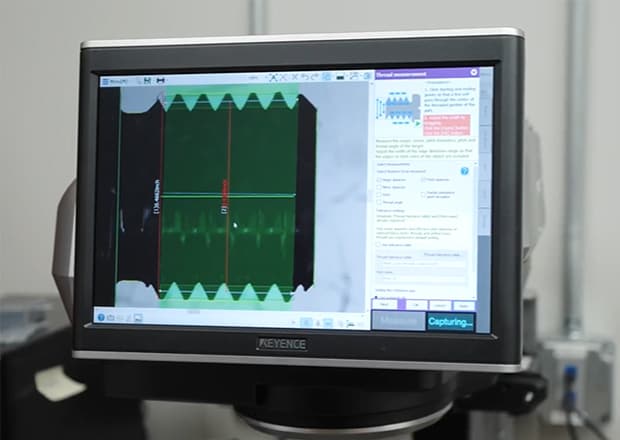

Optical Comparator (Profile Projector)

BG Automation Boosts Throughput and Simplifies Inspection with KEYENCE IM Series

BG Automation is leading contract manufacturers serving the automotive, aviation, and agricultural industries. Their core capabilities include precision machining of components that connect to critical vehicle systems, requiring consistent quality and high throughput. Known for integrating automation throughout their operations, BG Automation sought to bring the same efficiency to their quality inspection process.

We’re here to provide you with more details.

Reach out today!

Challenge: Manual Inspection Slowing Down Production

Before adopting a new measurement solution, BG relied heavily on conventional inspection tools such as calipers, micrometers, radius gauges, height stands, and an optical comparator. While effective, these methods were time-consuming and operator-dependent, often requiring 10 to 15 minutes per part for inspection. With high production volumes, the delay in inspection directly affected throughput and created bottlenecks between machining and quality control.

Solution: KEYENCE IM-8000 Series Instant Measurement System

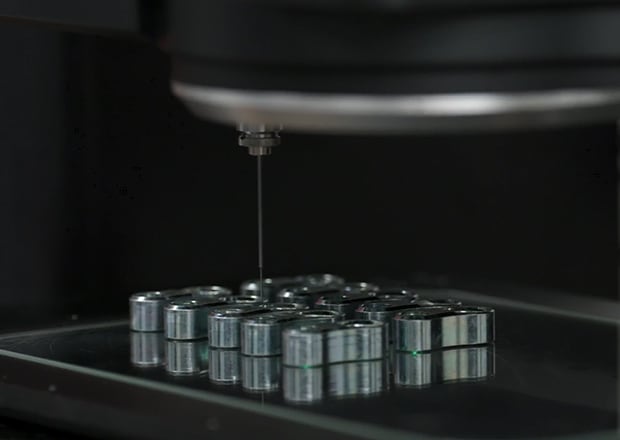

BG Automation turned to the KEYENCE IM Series, based on a recommendation from their quality manager, who had used the IM-7030 at a previous employer. The team adopted the IM-8000 Series, leveraging its automated, high-speed measurement capabilities and multi-part inspection features.

“We use a lot of automation here at BG, so it made sense to utilize the IM to automate inspection,” a BG representative shared. The IM System aligned with their mission to reduce manual work and improve consistency.

Results: Accuracy, Speed, and Ease of Use

The most immediate benefit was time savings. Parts that previously took 10–15 minutes to inspect now take just seconds—and even faster when using the multi-part feature.

“We’re able to take those seconds and turn them into fractions of seconds,” they noted.

Additional key benefits included:

- Ease of use: “KEYENCE gives you a user interface that basically turns anybody into an inspector.” With simple programming tools and intuitive visual guidance, even non-inspectors and machinists can quickly learn to operate the system.

- Offline programming: BG can now program measurement routines directly from CAD files without using the system itself, improving efficiency and minimizing downtime.

- Material versatility: The IM accurately measures steel, aluminum, and plastic parts, including black plastics, which were previously difficult to inspect with clarity.

- Instant traceability: Operators simply scan a QR code from an inspection report to instantly load the correct measurement program—no need to search or identify file names.

- Low cost of ownership: The IM offers in-house annual recertification, eliminating the recurring costs typically associated with third-party calibration services.

Get detailed information on our products by downloading our catalog.

View Catalog

Impact: A New Standard for Quality at BG Automation

With the KEYENCE IM System, BG Automation has transformed their inspection process, making it faster, more repeatable, and accessible to more team members. The combination of accuracy, ease of use, and production speed has resulted in smoother communication between inspection and machining, improved throughput, and greater confidence in final part quality.

“The IM has been worth it for me because it’s so easy to use and easy to cross-train,” BG concluded. “Not just inspectors, but machinists as well can come in and use it.”

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

See common optical comparator application examples measured on the IM Series Instant Measurement System. Application examples include: turned parts, machined parts, springs, stampings, fasteners, gaskets, etc.