Optical Comparator (Profile Projector)

Ensuring Precision Manufacturing in Medical Manufacturing

Key Takeaways

- Precision measurement is critical in medical manufacturing to ensure patient safety and regulatory compliance.

- Multisensor systems outperform optical inspection systems for complex geometries and diverse materials.

- Integrated multisensor data enables traceability and supports statistical process control (SPC).

- Automated multisensor inspection increases throughput while reducing operator training and setup time.

- Temperature compensation and combined contact/non-contact probes maintain accuracy across conditions.

The production of medical devices requires unwavering precision. A single measurement inaccuracy might jeopardize patient safety and regulatory compliance since lives depend on components that fulfill precise specifications. Simply put, the stakes are too high for anything less than flawless accuracy and precision medical manufacturing.

The Importance of Precision Measurement in Medical Manufacturing

Innovation in healthcare is based on precision medical manufacturing. Medical equipment must operate perfectly in harsh environments. Micron level tolerances are necessary for surgical instruments, pacemakers, and heart valves. Device failure or patient injury might result from even the slightest variation.

Regulatory bodies like the FDA impose strict quality standards. These requirements go beyond basic functionality, as every component must meet documented specifications. Manufacturers need proof that their products consistently deliver expected performance. This documentation starts with accurate measurement data.

Patient safety drives every decision in medical manufacturing. A faulty hip implant can cause years of pain and mobility issues. Defective surgical instruments can compromise operations. Poorly manufactured catheters can lead to serious complications. Precision measurement medical manufacturing prevents these catastrophic outcomes.

We’re here to provide you with more details.

Reach out today!

Measurement Challenges in Medical Manufacturing

Certain devices present unique measurement challenges that may affect precision medical manufacturing. Often, components have complex geometries with precise tolerances. Flexible polymers and biocompatible metals are examples of materials used. Surface coatings on different products may also vary greatly from one another. It is hard for conventional measurement methods to deal with this variability.

Speed presents another difficulty. Timelines for production demand fast measurements without sacrificing accuracy. High-volume production cannot use manual inspection techniques because they are too sluggish. Accuracy and speed must be provided by automated solutions.

Surface properties complicate measurement tasks. Reflective surfaces can interfere with optical systems. Transparent materials may not provide clear measurement references. Measurement pressure can cause flexible components to bend. Different measurement techniques are needed for each substance.

The accuracy of measurements is impacted by temperature and ambient conditions. Temperature swings occur in manufacturing settings, and sensitive components may be affected by humidity levels. Measurement mistakes are introduced by vibration from adjacent equipment. Robust measurement systems must compensate for these variables.

Overview of Key Measurement Techniques

Two primary measurement approaches dominate medical manufacturing. Optical Inpsection Systems provide rapid single-point measurements. They excel at 2-dimensional checks and high-speed sorting applications. These systems work well for many quality control tasks.

Multisensor measurement medical devices offer comprehensive inspection capabilities. These systems combine multiple measurement technologies, like contact probes and laser sensors, to handle diverse measurement requirements.

Differences Between Optical Inpsection Systems and Multisensor Measurement Systems in Medical Applications

Optical Systems prioritize ease of use and rapidity as they swiftly measure particular dimensions. But they don't have the adaptability required for intricate medical parts. Optical Systems are most effective when used for 2D inspections.

The IM-X System provides comprehensive measurement capabilities. It handles complex geometries that challenge single-sensor systems. Several measurement technologies are compatible with one another. Thanks to this integration, multiple measurement setups are no longer necessary.

The level of precision required varies by method. 2D measurements are usually accurately measured by Optical Systems. LM-X systems achieve superior precision in a variety of measuring activities. They maintain accuracy regardless of component complexity or material properties.

3D capabilities and precision set Multisensor Systems apart. Both Optical Systems and Multisensor Systems offer equivalent lighting capabilities, requiring similar effort when measuring reflective and transparent surfaces. However, The IM-X System provides superior 3D measurement precision and offers a variety of methods to measure a single dimension, providing the optimal measurement technology for each specific application.

Get detailed information on our products by downloading our catalog.

View Catalog

Medical Industry Applications Benefiting from Advanced Measurement

Although it may seem minimally correlated, accurate implant measurements are critical to patient results. Accurate dimensional specifications are necessary for hip and knee replacements. Bone screws require precise thread measurements. Dental implants need to fit the patient's anatomy precisely. These crucial criteria are confirmed by sophisticated measurement equipment.

Surgical instrument inspection protects patient safety. Forceps, scissors, and clamps require sharp, precise edges. Endoscopic tools feature complex geometries. Measurement systems verify cutting edges, joint alignment, and surface quality. These inspections prevent instrument failures during procedures.

Catheter inspection addresses unique measurement challenges. These flexible devices feature varying diameters along their length. Wall thickness must remain consistent throughout. Tip geometry affects performance significantly. Catheter measurements require specialized approaches that account for material flexibility.

Orthopedic implant inspection is required for safety and function. Hip and knee replacements must match exact bone dimensions. Surface texture affects bone bonding, while dimensional accuracy determines implant lifespan. Advanced measurement systems verify all critical specifications.

Tubing applications span numerous medical devices. IV tubes, breathing circuits, and drainage systems all require precise dimensions. Wall thickness variations can cause flow restrictions. Diameter consistency affects device performance. Measurement systems verify these parameters efficiently.

Minimally invasive devices present unique challenges. These components feature extremely small dimensions. Dimensional accuracy becomes even more critical as assembly tolerances shrink to microscopic levels. Advanced measurement systems handle these demanding requirements.

Why Multisensor Measurement Systems Are the Future of Medical Manufacturing

Medical device quality control continues evolving toward comprehensive inspection. Single-sensor systems cannot meet growing complexity demands, while multisensor platforms provide complete measurement solutions.

Manufacturing efficiency drives the adoption of integrated measurement systems. One platform with many measurement technologies cuts down on setup time. Operators need little training for a wide range of measurement tasks. In quality control, reliability and consistency improve.

Multisensor systems are unique in their ability to integrate data. They automatically gather extensive measurement data. This data supports traceability and statistical process control requirements. Manufacturers can identify trends and prevent quality issues proactively.

Future medical devices will become even more complex. Combination products merge multiple technologies. Smart implants include electronic components, while biodegradable materials introduce new measurement challenges. Multisensor systems provide the flexibility needed for these innovations.

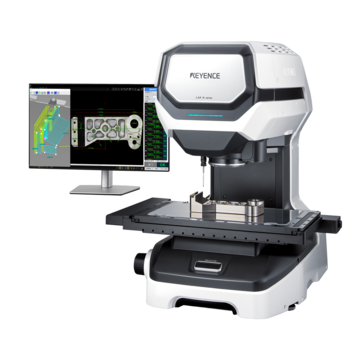

KEYENCE IM-X: A Multisensor Solution Tailored for Medical Manufacturing

Multiple measurement technologies are combined in the KEYENCE IM-X system. Contact probes are used to measure dimensions precisely. Non-contact applications are controlled using laser sensors and vision systems to confirm marks and 2D and 3D dimensions, removing bottlenecks in measurement.

One of IM-X's primary advantages for precision medical manufacturing is its remarkable adaptability. With three types of measurement, the system is able to handle a wide range of shapes and materials. It remains accurate in a variety of measurement jobs. Compared to several single-sensor systems, the setup time is much reduced.

Accuracy is preserved in a variety of settings thanks to temperature correction. Depending on the temperature, the system modifies measurements. Temperature-related measurement mistakes are avoided because of this function. Reliable quality control is supported by consistent precision.

User-friendly software simplifies complex measurement tasks. Operators can create measurement programs quickly. The system guides users through setup procedures and automated measurement routines, reducing operator training requirements.

Medical applications for the IM-X span the entire device manufacturing spectrum. Implant manufacturers use it for dimensional verification and assessment. Surgical instrument producers rely on it for edge sharpness and joint alignment checks. Catheter manufacturers benefit from their flexible material handling capabilities, as previously discussed.

The system efficiently manages transparent and reflective materials. The accuracy is maximized through multiple forms of measurement. Multiple measurement systems compensate for difficult surface dimensions. Because of its adaptability, specific measurement tools are no longer necessary.

Integration into existing quality control protocols also happens seamlessly. The IM-X system connects to manufacturing execution systems and supports standard communication protocols. Quality data flows directly into statistical process control systems.

Enhance your precision medical manufacturing capabilities with KEYENCE LMX and experience the difference comprehensive measurement makes. Contact our experts to find out how multisensor technology might improve your quality control procedures.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

How does the IM-X system handle varying materials in medical devices?

The IM-X has a variety of options to select the optimal measurement technology for each material, adapting to reflective, transparent, or flexible surfaces without manual adjustments.

Can IM-X measurements be integrated into existing quality control protocols?

Yes, the IM-X system connects seamlessly to manufacturing execution systems and supports standard communication protocols for direct data integration.

What advantages do multisensor measurement systems offer over optical inspection systems?

Multisensor systems provide comprehensive measurement capabilities, handle complex geometries, and maintain superior accuracy across diverse materials and applications.

Can multisensor measurement systems handle reflective or transparent materials commonly found in medical devices?

Yes, multisensor systems like the IM-X automatically adapt to challenging surface properties by selecting the most appropriate measurement technology for each specific application.

We’re here to provide you with more details.

Reach out today!