Optical Comparator (Profile Projector)

KEYENCE Multisensor Measurement Systems vs Other Measurement Systems

Key Takeaways

- Multisensor systems integrate tactile, confocal laser, and optical measurement in one platform.

- Single-setup inspections cut cycle time and increase production throughput.

- Consolidation improves measurement accuracy consistency and reduces shop floor footprint.

- Intuitive software, automated feature recognition, and drag-and-drop reduce training and setup time.

Accurate measurement skills that can meet production goals are essential for manufacturing. Comparing multisensor measuring systems to conventional single-technology methods reveals a substantial improvement.

What Are Multisensor Measurement Systems?

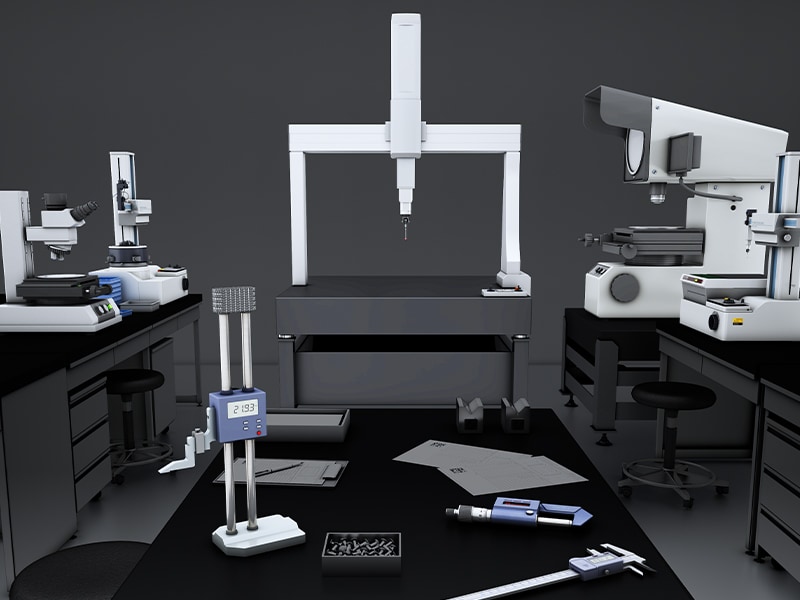

Multiple measuring technologies are combined into a single platform by multisensor measurement systems. Usually, these systems incorporate tactile probing, confocal laser for height and depth measurement, and optical measuring. Operators can measure various features thanks to the integration without having to move components or switch between different machines.

Unlike traditional coordinate measuring machines that rely on single measurement methods, multisensor systems adapt their approach based on the specific feature being measured. A single part might require optical measurement for 2D features, a confocal laser for complex geometries, and a tactile probe for critical dimensions. With several different methods of measurement, you have the option to use your preferred type of method for each dimensional callout.

Vision measurement systems form a core component of multisensor platforms. These systems capture detailed images of parts and extract dimensional data through sophisticated software algorithms. When combined with other measurement technologies, they create a versatile measurement environment that handles diverse inspection requirements.

We’re here to provide you with more details.

Reach out today!

How Do Multisensor Systems Compare to Other Measurement Technologies?

Different measurement approaches serve specific purposes, but each has limitations when used independently. The table below illustrates how multisensor systems address these limitations:

| Technology | Capabilities | Limitations | KEYENCE Multisensor Advantage |

|---|---|---|---|

| Hand Tools (Calipers, Micrometers) | Basic dimensional checks, manual | Operator variability, slow, subjective | Multisensor systems automate measurements with high accuracy and repeatability, reducing errors. |

| Optical Comparators | 2D measurement, profile comparison | Limited 3D capability, manual setup | Multisensor systems integrate optical measurement capabilities and incorporate laser and probe technologies to measure depth and height within a single system. |

| Single-Sensor CMMs | 3D and GD&T inspection | Limited to one measurement type, longer inspection times | Multisensor systems measure multiple features simultaneously with simple programming (no CMM programmer required). |

| Portable/Arm CMMs | Flexible 3D measurement on the shop floor | Sensitive to vibration, limited automation | KEYENCE systems combine high accuracy/repeatability along with shop floor usability. |

| Laser Scanners | High-resolution surface scanning | Require line-of-sight, sometimes slower | Multisensor systems combine a confocal laser with contact and vision methods, plus automated measurement with little start-up time. |

Scroll

The multisensor vs CMM comparison reveals significant advantages in flexibility and measurement speed. Traditional CMMs excel at precision but often require lengthy setup times and programming. Multisensor systems reduce these bottlenecks through automated measurement selection and simplified programming interfaces.

Key Benefits of KEYENCE Multisensor Measurement Systems

KEYENCE multisensor systems are superior to conventional measurement techniques in a number of ways. The variety of measurements is the main advantage. A single system handles features that would normally require several specialist machines. Because of this consolidation, less floor space and equipment are needed.

Speed represents another significant advantage. Multisensor measurement benefits include the ability to measure multiple features simultaneously. While traditional systems might require repositioning parts between different measurement stations, multisensor systems complete comprehensive inspections in single setups.

Accuracy consistency across different measurement types provides additional value. When transferring components between various measurement systems, traditional methods can cause variation. Throughout the measuring procedure, multisensor systems keep constant reference frames.

Contact and Non-Contact Capabilities and Automation

Technical capabilities of multisensor systems extend beyond simple measurement integration. These platforms combine contact and non-contact measurement methods seamlessly. Optical vs tactile measurement approaches each offer specific advantages, and multisensor systems leverage both as needed.

Non-contact optical measurement excels at measuring delicate surfaces, complex geometries, and features that would be damaged by tactile probing. Contact measurement provides superior accuracy for critical dimensions and reference features.

Advanced software guides users through measurement sequences and automatically adjusts measurement parameters such as focusing and part location recognition. Training requirements and measurement variability are reduced by this automation.

Programming and setup are also made simple. Operators don't need to know a lot of programming to construct measuring routines because of intuitive interfaces. Drag-and-drop functionality and automated feature recognition streamline the measurement setup process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

When to Choose Multisensor Measurement Systems

Several factors indicate when multisensor systems provide the best measurement solution. Parts with diverse feature types benefit most from multisensor capabilities. Components requiring both 2D and 3D measurements and critical dimensional verification represent ideal applications.

Production environments with high throughput requirements favor multisensor systems. The ability to complete comprehensive inspections in single setups reduces cycle times and increases measurement capacity. Quality control departments managing diverse part portfolios find multisensor systems particularly valuable.

Cost considerations also support multisensor selection. While initial investment might exceed single-technology systems, the consolidation of multiple measurement capabilities often provides better long-term value.

Case Studies: IM-X vs. Traditional Systems

Multisensor measurement systems provide benefits in many real-world applications. When automakers use KEYENCE IM-X systems, measurement times are shortened versus conventional CMM techniques. The ability to measure engine components with mixed surface types and critical dimensions in a single setup eliminates multiple handling operations.

Electronics manufacturers benefit from the precision optical capabilities combined with tactile verification. Circuit board assemblies require measurement of component placement, solder joint profiles, and critical dimensions. Traditional approaches would require multiple specialized systems, while multisensor platforms handle all requirements comprehensively.

Medical device manufacturers particularly value contamination-free measurement capabilities. Non-contact optical measurement handles sterile components without risk of contamination, while tactile measurement verifies critical functional dimensions.

KEYENCE IM-X Series: A Closer Look

The KEYENCE IM-X series represents advanced multisensor measuring technology. These devices combine precise tactile probing, a confocal height & depth laser , and high-resolution optical measuring into small platforms. The integration offers measuring flexibility without compromising speed or accuracy.

The IM-X series stands out from competing products thanks to its software capabilities. Training needs and setup times are decreased via intuitive programming interfaces. Automated measurement processes yield consistent results throughout production runs and adjust to part differences.

Stability and accuracy are prioritized in the hardware design. Accurate measurements are maintained in a variety of environmental circumstances using precision mechanical systems, temperature correction, and vibration isolation. Because of these characteristics, the systems can be used in both production and laboratory settings.

For a wide range of measuring needs, KEYENCE multisensor measurement systems provide complete solutions. To offer better measurement performance, the systems integrate cutting-edge software features with tried-and-true measuring technology.

Upgrade your measurement capabilities with KEYENCE IM-X. Contact us today to set up a demo or speak to a specialist.

Get detailed information on our products by downloading our catalog.

View Catalog

Frequently Asked Questions

What maintenance requirements do multisensor systems have?

Multisensor systems require minimal routine maintenance, mainly periodic cleaning of optical components and occasional calibration checks. The integrated design reduces maintenance complexity compared to managing multiple separate measurement systems.

Can multisensor systems handle both 2D and 3D measurements?

Yes, multisensor systems excel at both 2D and 3D measurements. They combine optical measurement for 2D features with a tactile probe and confocal laser for comprehensive 3D analysis.

Are multisensor measurement systems easy to operate?

Advanced software interfaces make multisensor systems accessible to operators with varying skill levels. Automated programming and intuitive controls reduce training requirements significantly.

What industries benefit most from multisensor measurement systems?

Automotive, electronics, medical devices, and aerospace industries particularly benefit from multisensor capabilities due to their diverse measurement requirements and precision demands.

We’re here to provide you with more details.

Reach out today!