Measurement Sensors

Dimension Measurement

Displacement Measurement

Guide to Boosting Production Line Efficiency with Measurement Systems

Manufacturers don’t have the luxury of waiting for productivity to sort itself out. Whether it’s a bottleneck in assembly or inconsistencies in part dimensions, the cost of inefficiency shows up fast and hits hard.

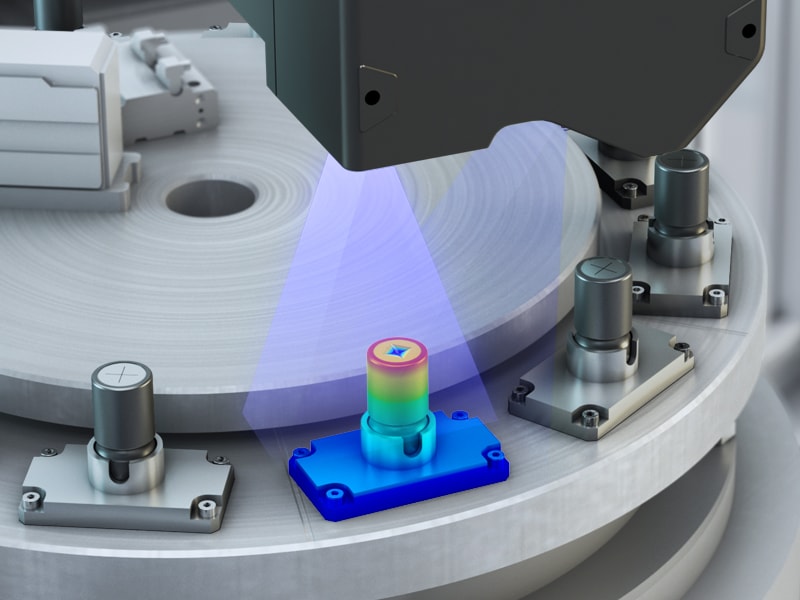

To support production line efficiency, operators can implement measurement systems to help maintain output without constant manual input. Measurement systems supply the visibility needed into what is actually happening along a production line; they capture size, appearance, volume, and variations without disrupting the process. These sensors range from 1D laser sensors to high-speed 3D profilers and confocal displacement sensors, giving the ability to monitor dimensions, detect defects, and verify that all parts are in position in milliseconds. Sensors also provide a consistent data stream that helps operators make real-time decisions.

Why Production Line Efficiency Matters

No production team sets out to waste time or materials, but when cycle times creep up, scrap piles grow, or one machine slows the rest, it doesn’t take long for small issues to fan out and affect the entire line.

Having an efficient production line is about getting the most out of every part of the process without pushing the system to a breaking point. It keeps output consistent, reduces the number of manual inspections to look for errors, and makes sure resources aren’t tied up in rework. An efficient line means an efficient team; operators have the information to make adjustments before small issues become big problems. Maintenance teams don’t have to play catch-up. Managers can have a clearer picture of how labor, equipment, and materials are actually being used.

Production line efficiency doesn’t happen by accident either. Measurement systems contribute to it in striking ways by providing data on product measurements and telling operators where to look for possible defects or flaws; they remove the guesswork that helps manufacturers hit an ever-moving efficiency target.

We’re here to provide you with more details.

Reach out today!

Key Metrics for Improving Production Efficiency

Efficient production lines require measurable proof that equipment is running as expected, that output is meeting demand, and that quality isn’t slipping. Instead of managers having to rely on instinct, metrics provide that proof by tracking performance.

One of the best ways to monitor production line efficiency is through overall equipment effectiveness (OEE). This metric combines availability, performance, and quality all into one score. Availability tracks whether machines are running when they are scheduled to be; performance reflects whether they are running at their expected speeds; quality measures the percentage of units produced without defects. A drop in any one of these areas will drop the OEE score and give a clear indication of where attention is needed.

Throughput is another key metric, representing the total number of acceptable units produced in a given time frame. A consistent throughput rate offers a baseline for determining a production line’s pace and capacity. If an operator is alerted to a deviation in this metric, particularly after a change in process or materials, it can highlight areas that need additional maintenance or adjustments.

Cycle time and takt time are metrics that assess whether a production line is on track to meet demand. Cycle time measures how long it takes to produce a single unit. Takt time, on the other hand, is based on customer demand, indicating how many units need to be produced within a particular time frame. If cycle time exceeds takt time, it signals that the line is falling behind, whereas if takt time is overtaking cycle time, the line is ahead of schedule and could be overproducing product.

Yield is the connection between efficiency and product quality. This metric reflects the percentage of units that meet the product specifications on the first try. A declining yield often points to inconsistent setups or missed defects, issues that measurement systems are specifically designed to catch.

These metrics, and others, are only useful when they are tied to real-time data. Measurement systems provide accuracy and repeatability to the process, allowing teams to identify the root cause of issues before there is a shift in performance. These systems turn metric data into actionable information, regardless of whether it's a gradual slowdown in cycle time or an increase in part variation.

We’re here to provide you with more details.

Reach out today!

Types of Measurement Systems for Production Lines

Choosing the right measurement system to improve production efficiency starts with knowing what needs to be measured, how fast the production line needs to move, and what conditions the line operates under. KEYENCE offers a wide range of non-contact systems that support everything from basic dimensional checks to high-speed inline profiling.

1D laser displacement sensors measure a single-axis distance between the sensor and a target. Sensors like the LK-G5000 Series are built for speed and offer a high sampling rate of 392 kHz, making them ideal for fast-moving lines. They’re commonly used to measure one dimension, such as checking height, thickness, or gap width on parts.

2D and 3D laser profilers go a step further by scanning across the surface of a part to generate a complete profile of the object. The LJ-S8000 Series, for example, captures fine details across curved or complex shapes with imaging speeds as little as 0.2 seconds and accuracy of 2.8 µm. It’s well-suited for checking adhesive bead volume and detecting surface textures & defects and works perfectly in applications where the shape and consistency of an object are just as important as the raw dimensions.

Confocal displacement sensors offer high precision on challenging surfaces. The CL-3000 Series uses a multi-color light source and quad-CMOS system to measure transparent films, reflective materials, and multilayered components. It can take stable readings even on moving targets and in tight spaces, or areas where temperatures run high (up to 200°C / 392°F). Confocal systems are often part of production lines that produce semiconductors, medical devices, and electronics, where even the small micron-level flaws need to be detected.

Understanding each sensor type's strengths helps make sure that measurement data isn’t just accurate but also that it contributes to production line efficiency goals.

Get detailed information on our products by downloading our catalog.

View Catalog

Strategies to Improve Assembly Line Efficiency with Measurement Systems

Real-time data from measurement systems help production teams spot delays, variations, and inefficiencies as they happen. Teams then use this data to adjust part spacing, improve timing, and coordinate stations without pausing production. Systems can also be improved through the adoption of strategies like the 5S method (Sort, Set in Order, Shine, Standardize, and Sustain) and process standardization, which further reduces the need for manual checks.

Implementing Measurement Systems to Maximize Output

Maximizing output begins with choosing the right system for the job, which means matching measurement tools to surface types, environmental conditions, and production speeds. These systems can be installed and integrated directly into existing production lines with minimal disruption and feed directly into dashboard ERP tools already in use. Teams can be trained to interpret and act on that data with the understanding that the data is just as important as the installation itself. Consistent output relies on more than just accurate data; it also needs that data quickly for rapid decision-making. When measurement systems are fully implemented into operations, they become a direct indicator of quality and meeting production targets.

KEYENCE can help boost your production line optimization and assembly line efficiency. Have more questions on how to improve production line efficiency? Contact us today!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Products

Applications

Dimension Measurement

- Thickness and Width Measurement

- Step Height Measurement

- Inner and Outer Diameter Measurement

- Measuring Angles

- Meandering/Edge Measurement

Displacement Measurement

- Positioning and Stroke Length Measurement

- Vibration and Runout Measurement

- Deflection Measurement

- Measuring Eccentricity