Optical Comparator (Profile Projector)

Thread Measurement in Manufacturing

Thread measurement in manufacturing processes forms the foundation of quality and precision. Certain methods often fall short when dealing with complex geometries and tight tolerances. Advanced measurement systems now provide manufacturers with the accuracy and speed necessary to maintain consistent quality standards.

We’re here to provide you with more details.

Reach out today!

Challenges with Traditional Thread Measurement Methods

Manual thread measurement techniques create bottlenecks in production workflows. These methods introduce human error and lack the repeatability needed for high-volume manufacturing. Contact measurement can also damage delicate threads or coated surfaces.

Traditional systems struggle with complex thread profiles and varying materials. Modern scanning solutions offer non-contact alternatives that eliminate these issues.

Optical comparator

Measuring microscope

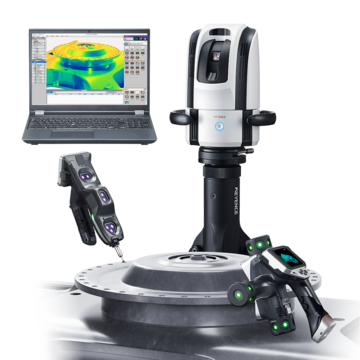

Optical CMM

Profile measurement system

Caliper

Micrometer

Common Thread Types and Metrology Challenges

Screw thread metrology covers various thread forms, including metric, unified, and specialty profiles. Each thread type presents unique measurement challenges. While coarse threads may have surface imperfections that make measurement more difficult, fine-pitch threads demand extraordinary precision.

One of the most important parts of thread checking is the pitch diameter measurement. Thread function and assembly quality are directly impacted by this dimension. Coordinate measuring machines are excellent at accurately recording these dimensions.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Internal vs External Thread Inspection

External thread measurement plays a dominant role in manufacturing quality control processes. External threads are more accessible for measurement equipment and offer better visibility during inspection.

Because of access restrictions, internal thread examination poses extra difficulties. Advanced CMM systems provide specialized probes and measurement strategies for internal thread inspection.

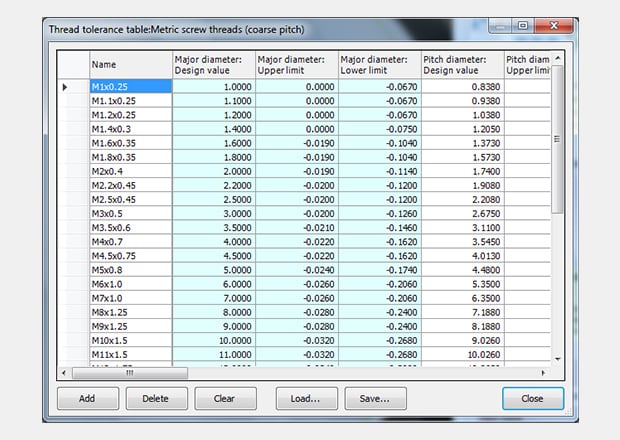

The Role of the Thread Class Tolerance Chart

The IM-X Series also allows you to create your own tolerance tables in a spreadsheet program and import them.

Systems for classifying threads define acceptable tolerance ranges for various purposes. While Class 3 threads offer tight tolerances for precision applications, Class 1 threads offer loose tolerances for simple assembly.

Built-in tolerance databases speed up the inspection process by eliminating the need for human tolerance management. To provide instant pass/fail results, high-precision measurement systems can automatically apply these restrictions.

How the IM-X Series Revolutionizes Thread Measurement

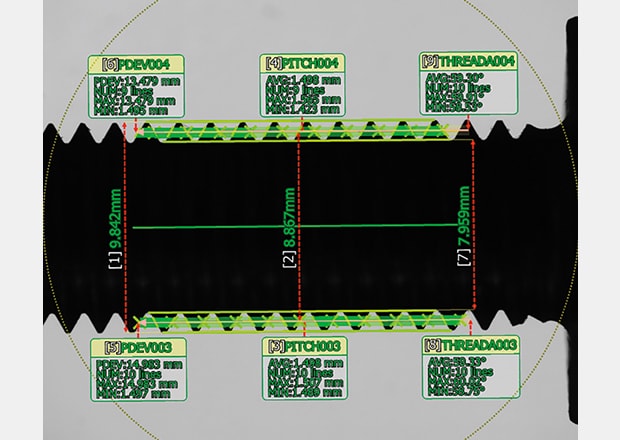

The IM-X Series represents a breakthrough in automated thread measuring tool technology. This device combines a high-resolution camera with complex measurement algorithms to enable precise thread analysis. Non-contact measuring eliminates the chance of part damage while maintaining exceptional precision.

The technology takes multiple measurements simultaneously and gives comprehensive thread analysis in seconds. Measuring up to 5000 dimensions on up to 1000 parts at once, the IM-X Series dramatically increases inspection throughput. Automatic focus adjustment and edge detection eliminate the need for manual setup between different part types. 3D profile measurement systems complement this technology by providing detailed surface topology data.

Applications of Thread Measurement in Various Industries

The quality of threads for fasteners and engine parts is crucial to the automotive production process. Due to safety regulations, aerospace applications require even stricter tolerances. Medical device manufacturing requires precise thread measurement for implants and surgical instruments.

Electronics manufacturing uses fine-pitch threads for miniaturized components. The IM-X system provides analysis by combining three sensor types: vision, probing, and laser. This approach provides the best thread geometry and analysis for electronic assemblies.

Key Features for Thread Measurement

For thread inspection, advanced measurement systems provide essential features. High-resolution cameras capture detailed thread profiles, and the geometry is automatically analyzed by advanced algorithms.

Workflows for quality control are streamlined through integration with manufacturing systems, which support data logging capabilities that track and ensure part traceability requirements. Intuitive user interfaces require no specialized measurement expertise to operate effectively.

Ready to learn more about thread measurement in manufacturing? Request a demo of our thread inspection systems today.

Discover more about this product.

Click here to book your demo.

FAQs

How does the IM-X Series handle thread pitch measurement?

The IM-X Series utilizes advanced optical measurement to precisely calculate pitch spacing across the entire thread profile.

Are thread gauges still necessary in digital thread metrology?

Digital systems can often replace traditional gauges, though some applications may still benefit from physical standards for calibration verification.

How are burrs or coating layers handled during thread inspection?

The system's software can distinguish between actual thread geometry and surface anomalies, such as burrs or coatings, through advanced image processing.

How can I fixture my parts for proper thread measurement?

Proper fixturing involves securing the part to maintain thread axis alignment while allowing clear optical access to the measurement area. The IM-X Series provides a 360-degree rotary chuck that holds threaded components in place for comprehensive thread inspection.

We’re here to provide you with more details.

Reach out today!

Related Downloads

Brochure for the WM-6000 series Wide-Area CMM. A portable setup with a wireless handheld probe that enables users measure large parts and equipment.

Brochure for the XM-5000 Series Handheld CMM. Portable CMM to easily and accurately measure 3D and GD&T features anywhere including the shop floor and in the machine tool.