Industrial Laser Marking Systems / Laser Markers

How Does Laser Cleaning Work?

-

Tags:

- Laser Cleaning , Electric Vehicle , Battery

Cleaning metals, resin, and other materials is always in demand for a wide range of industries. With research increasing about how chemicals drastically increase climate change and health issues, laser cleaning is becoming necessary. Not only does it help the environment, but it also is the next step to keeping costs low and efficiency high. In the following, we’ll take a look at how KEYENCE’s laser marking systems outperform chemical cleaning and standard laser cleaning machines.

Exploring the Process of Laser Cleaning

Laser cleaning is the process of cleaning a surface by transforming its coating into gas. It begins with a high peak power laser with short pulse frequencies shooting into the surface of a film and heating it. Then, the coating is removed by vaporization. Laser cleaning removes coatings such as enamel, wire sheath, or resin for various reasons. Resin coatings may be removed to review a defective mold. Wire sheath may need to be removed for a productive electrical connection.

Other notable aspects of the laser cleaning process include impressive precision and control over the intensity of the laser. Moreover, it surpasses traditional methods in essentially all regards.

This is especially true when it comes to its non-contact approach, which heavily mitigates the chances of damaging materials. Manufacturers who choose to clean with a laser also enjoy a dry cleaning process that doesn’t require water or chemicals.

Laser cleaning with KEYENCE's UV Laser Marker MD-U Series and Hybrid Laser Marker MD-X Series is a more efficient, environmentally friendly, healthy, and cost-effective alternative than chemicals or any other conventional laser cleaner.

We’re here to provide you with more details.

Reach out today!

Key Components of Laser Cleaning Equipment

How does laser cleaning work exactly? In addition to the different types of laser cleaning machines, several universal critical components are involved. Laser cleaning technology would be nothing without the engineering behind each component.

A few essential aspects regarding the designs of laser cleaners include the following:

- Optic and beam delivery systems

- Different laser types and applications, such as fiber laser cleaning or UV laser cleaning

- Scanners for precise laser cleaning

- Multi-layered safety systems

- More innovative cooling abilities

- Exhaust system for fumes stemming from vaporized debris

Laser cleaning benefits are no secret, but that isn't to say the process doesn't come with its own due diligence. While it can significantly mitigate damage to surface material, a bit of preparation may still be needed.

Discover more about this product.

Click here to book your demo.

Laser Cleaning Applications

The best laser cleaning systems are KEYENCE’s UV Laser Marker MD-U Series and the Hybrid Laser Marker MD-X Series.

The Hybrid Laser Marker MD-X Series is perfect for cleaning out epoxy resin, abs resin, PBT, stainless steel, iron, aluminum, and rubber. It utilizes a high peak power and a wavelength of 1064 nm to absorb any material needing to be removed. The high heat and precise beam-spot control eliminate the risk of damaging the internal circuit.

The UV Laser Marker MD-U Series is great for cleaning resin, nickel, copper, gold, ceramic, silicon, and rubber. The MD-U also starts by using a 1064 nm laser and then converts it to a 355 nm laser. The 1064 nm laser passes through two crystals and minimizes the wavelength into a 355 nm laser for minimal heat stress and high absorption. The 355 nm then starts the photolytic degradation process to break the bonds directly instead of ruining the base material.

Both laser cleaners ensure consistency across parts. They feature 3-Axis lens technology, an IP64 environmental rating, and a built-in camera that guarantees uniformity. Also, the power monitor function ensures that the power marking is equal among all parts.

Both laser markers do not damage surfaces and may only take a few minutes to complete the entire laser cleaning process. The MD-U and the MD-X also allow for a clean process without consumables, which lowers the overall cost and increases ROI.

*¹ Not available on ML-Z

*² Not available on MD-F and ML-Z

-

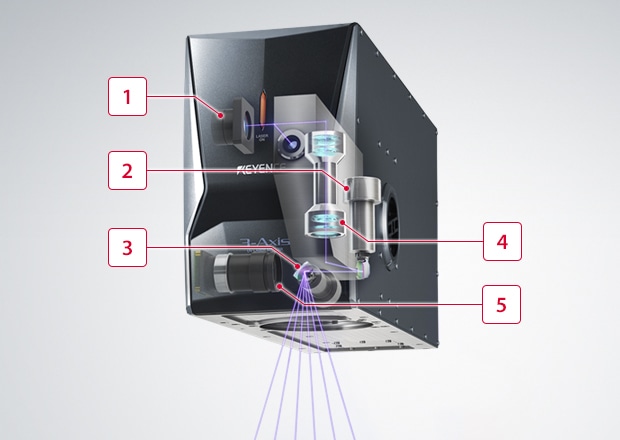

1Thermopile power monitor*¹ : Laser output measurement

-

2X-axis scanner : Laser position galvanometer

-

3Y-axis scanner : Laser position galvanometer

-

4Z-axis scanner : Variable focal distance

-

5Multi-function camera*² : Focal distance measurement, 2D code reading and verification, print placement verification

Get detailed information on our products by downloading our catalog.

View Catalog

Laser Cleaning Versus Traditional Cleaning Methods

There are some apparent upsides to cleaning lasers compared to traditional methods. Of course, traditional takes on industrial cleaning will be around for a long time, but manufacturers are looking for ways to improve. The breakdown below offers a comparison between using a laser for cleaning and sticking to traditional practices.

Laser Cleaning

- Contaminants are vaporized and removed through the process of ablation.

- Makes use of a high-powered laser beam that avoids damaging the material’s surface.

- Minimal environmental impact and a dry cleaning experience.

- Precise control over the laser and coverage of surface area, in addition to the duration of laser pulses.

Traditional Cleaning

- Commonly relies on lots of water and chemical solutions to achieve an end result.

- Requires much more abrasive and physical labor, such as scrubbing and solvent cleaning.

- Effective for certain applications but isn’t nearly as efficient or cost-effective.

- Results tend to be less consistent and precise.

- Usually requires direct contact with the surface, which can easily lead to damage.

There is always room for improvement, but in light of laser surface cleaners, manufacturers are happy to make the switch. As laser cleaning equipment evolves with time, traditional cleaning methods will only become increasingly obsolete.

We’re here to provide you with more details.

Reach out today!

What Works Well for Laser Cleaning? What Doesn’t?

KEYENCE’s laser markers combat long work time and extra costs with their built-in camera, 3-Axis technology, and IP64 rating. The camera, alongside its displacement sensor, provides a full-field auto-focus function. The auto-focus positions and aligns the laser precisely onto the spot that is to be marked or cleaned. The 3-Axis system makes it possible to program complex shapes into the laser cleaner without any runoff or distortion. Then, the IP64 rating allows for markings or a cleaning process to occur in production processes that are heavily contaminated with dirt and debris. Because of this, laser cleaning can happen efficiently and precisely without error or damage to the product.

On the other hand, conventional laser cleaners have blurred focus, position accuracy is poor, and set-up can take more time as alignment is repeatedly dialed in. Without a variable focal point, surfaces with height differences or curves cannot be effectively cleaned. As a result, uneven cleaning or damage to the surface occurs.

IP64 Rated Marking Head

The MD-X Series and MD-U Series use a proprietary sealing method to securely protect optical components. This ensures that these components are not affected by factors such as dirt, dust, and water droplets, which provides environmentally resistant performance and allows for stable operation in even the harshest environments. These lasers have an enclosure rating equivalent to that of the fanless marking head of our MD-F Series fiber laser markers.

Get detailed information on our products by downloading our catalog.

View Catalog

Cost Advantages of Laser Cleaning

KEYENCE’s laser cleaning systems require a one-time payment– buying the laser marker.

KEYENCE’s laser systems last four times longer than standard laser systems, so replacement fees are decreased when buying the MD-U or MD-X. Moreover, labor costs decrease because of the AI engineering of KEYENCE’s systems. The MD-U and MD-X can utilize the built-in internal camera for XY tracking of parts to eliminate the need for fixtures or precise part placement, so no time is wasted with manual setups. Lastly, since the MD-X and MD-U do not use chemicals, this eliminates the cost of biohazard cleanup, regulatory fees, and Personal Protective Equipment (PPE).

Discover more about this product.

Click here to book your demo.

Environmental Advantages of Laser Cleaning

The reduction in environmental damage from using laser cleaning instead of chemicals is drastic.

Using chemicals is extremely harmful to the environment. Laser cleaning does not require any gathering of chemicals. Nor does laser cleaning emit gas into the air contributing to climate change or health issues. Further, laser cleaning does not require any disposal of chemicals. Laser cleaning does not produce any toxic waste or biohazards that may seep into water or air.

Chemicals are not used in laser cleaning with the MD-U or MD-X, making it much more environmentally friendly.

We’re here to provide you with more details.

Reach out today!

Safety With Laser Cleaning

Laser cleaning will not result in disease, burns, or irritation because it simply uses natural heat absorption. The MD-U and the MD-X are very easy to use, so there is a limited risk of injury. Furthermore, there is no risk of cross-contamination explosions because the MD-X and MD-U do not use any toxic chemicals.

Alternatively, cleaning resin or metals with chemicals is inherently dangerous. Chemicals commonly used for cleaning procedures are nitric acid, hydrochloric acid, and phosphoric acid. These chemicals are extremely toxic to humans by contact and inhalation. The University of Massachusetts, Amherst, reports these chemicals can eat away at skin, eyes, respiratory systems, and gastrointestinal systems by contact. One of the chemicals used, phosphoric acid, can cause kidney failure, central nervous system effects, or even death. Additionally, inhaling these chemicals can irritate the lungs and lead to bronchitis. Because of the danger, hands, body, and mouth must be covered while working with these chemicals.

Curious about our pricing?

Click here to find out more.

Convert to KEYENCE’s Laser Cleaning Today

You should not have to worry about environmental, health, or cost concerns when completing cleaning projects. Using KEYENCE’s laser markers can be your next step to feeling confident about your cleaning procedures. Learn more about our laser marking systems to find the best system for your project!

If you have any questions, ask KEYENCE—our knowledgeable team will get back to you quickly. We pride ourselves in our support for our customers throughout the selection process to operations with on-site operating instructions, along with industry-leading after-sales support.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

![LASER PROCESSING REPORT [Cutting an Acrylic Plate]](/img/asset/AS_48505_L.jpg)

![Laser Processing Guidebook STEP. 1 [What is Laser Processing?]](/img/asset/AS_46967_L.jpg)

![Laser Processing Guidebook STEP. 2 [Wavelength characteristics]](/img/asset/AS_46968_L.jpg)

![Laser Processing Guidebook STEP. 3 [Drilling/Cutting/Half-cutting]](/img/asset/AS_46969_L.jpg)

![Laser Processing Guidebook STEP. 4 [Coating/Film Layer Removal]](/img/asset/AS_46970_L.jpg)