Industrial Laser Marking Systems / Laser Markers

Laser Marking in the Automotive Industry

-

Tags:

- Laser Marking , Metal , Plastic

The automotive industry has been leading the charge for making laser marking a standard when it comes to part marking and traceability. Long-lasting, high-contrast markings are produced without damaging the components. More than just labeling, QR codes and barcodes can store detailed data to track parts from manufacturing to the end of a vehicle's life. If a defect is found in an automobile, the manufacturer needs to identify all defective parts and track down when and where those parts were produced. Supply chains will continue to become more complex, and laser marking will remain a dependable process for maintaining quality, managing warranties, and responding quickly to safety concerns.

How Automotive Laser Marking Improves Traceability & Compliance

Automotive laser marking creates a digital fingerprint for each component, enabling manufacturers to track parts from production through assembly and into finished vehicles. A holistic traceability solution, it meets stringent regulatory requirements such as NHTSA standards and international safety regulations. If or when recalls occur, laser-marked components are easily identified and replaced, reducing disruption and protecting consumer safety.

Also aiding anti-counterfeiting efforts by making parts, laser technology makes it more difficult to replicate illegally, protecting brand integrity and consumer safety in the aftermarket parts industry.

We’re here to provide you with more details.

Reach out today!

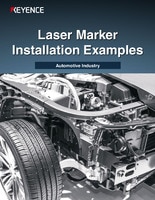

Common Applications of Laser Marking on Automotive Parts

Car part laser marking helps automotive manufacturers to apply marks on a number of parts. Engine components like pistons, bearings, camshafts, gears, and cylinder heads receive unique identifiers that withstand extreme heat and friction.

Electronic modules carry laser-marked serial numbers and production data that remain readable throughout the vehicle's lifespan. Safety-critical parts including airbag components and brake systems feature tamper-proof markings for regulatory compliance. Even interior and exterior trim pieces receive laser-marked batch codes and material information to support quality control and recycling efforts.

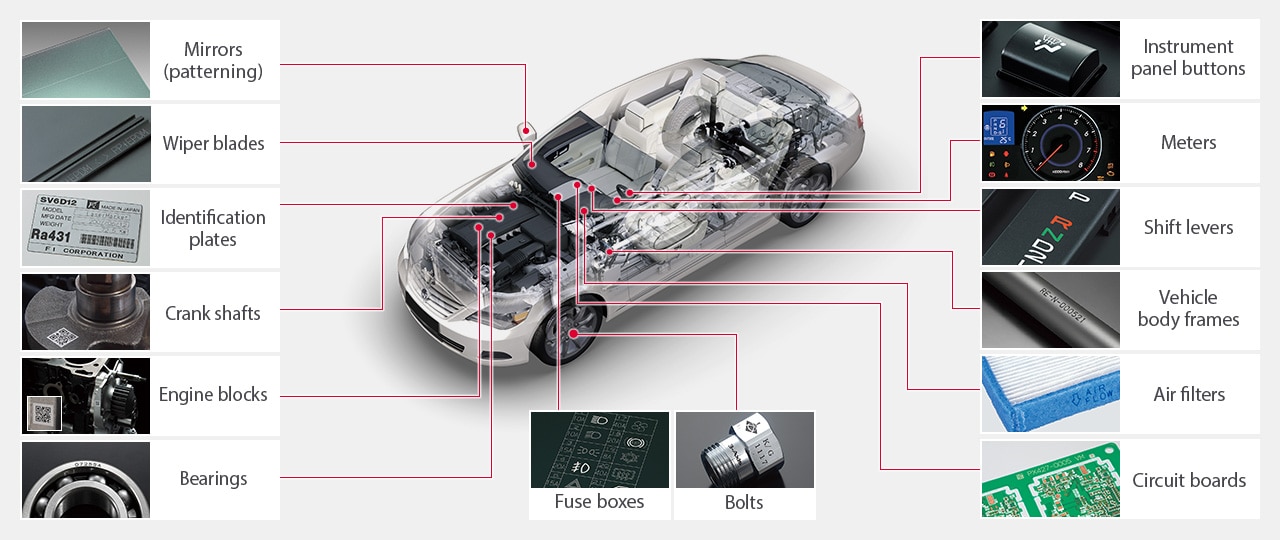

Shift lever

Seat rail

Gear

Bearing

Inverter case

Motor housing

Transmission case

Engine block

Advantages of Laser Marking Over Traditional Automotive Part Marking

Laser marking on automotive components outperforms conventional methods like ink printing, labels, and mechanical engraving in multiple ways. Unlike ink, laser marks won't fade, smudge, or degrade under harsh automotive conditions including extreme temperatures, vibration, and chemical exposure.

Because laser marking is a non-contact process, it protects the integrity of precision-engineered parts. Also, it adapts easily to different shapes and materials without requiring tooling changes. Not like traditional marking methods, laser marking eliminates the need for inks or labels, reducing costs and minimizing waste—key benefits for manufacturers prioritizing sustainability.

This process is essential to identify the make and model of the vehicle, as well as the country of origin. Laser marking is also used to put serial numbers on car parts so that they can be tracked if lost or stolen.

Some of the automotive industry's greatest challenges are safety, part alignment, and product changeover. Additionally, it can be difficult to achieve a consistent and even laser mark on curved or three-dimensional surfaces. Automotive manufacturers must carefully consider these challenges before deciding whether laser marking is the best solution for their needs.

With years of experience working with automotive industry clients, we have developed innovative and reliable products to safely meet these challenges and help you improve and automate your processes.

Learn how KEYENCE laser markers overcome common limitations to make automotive marking quick and easy.

Discover more about this product.

Click here to book your demo.

Laser Marking Technologies for Automotive Parts

Widely used in automotive applications, fiber laser marking is ideal for marks on metals such as aluminum, steel, and titanium, all with exceptional precision and durability. Laser systems produce high-contrast marks on engine blocks, transmission components, and structural elements. For plastic components like dashboards and electrical connectors, UV laser marking provides gentle yet permanent marking without material damage. CO2 laser marking excels at marking organic materials used in interior applications.

Automotive Parts: Reliability in the Industry

Safety is the #1 concern for manufacturers in the automotive industry. As such, high levels of history management and process control are necessary to ensure proper part traceability. Many automotive manufacturers and part suppliers have found that 2D code marking is a great way to establish this traceability. Part marking was once only required for major components, but it is now steadily spreading to include individual parts used in the construction of automobiles (typically over 20,000!). Considering the rapid increase in part marking, laser markers have become a go-to for manufacturers thanks to their tamper-proof marking and low running costs.

Overcoming Automotive Manufacturing Challenges with Laser Marking

When it comes to automotive production, laser marking is addressing a variety of manufacturing issues. The technology handles the industry's diverse material mix with consistent marking quality. Integration with automation systems enables high-speed marking without compromising production throughput. Advanced vision systems even verify mark quality in real-time, ensuring 100% readability.

Electric vehicle adoption will continue to grow in the years ahead. Because of its adaptability, laser marking will continue to meet the latest demands, including battery cell identification and high-voltage warnings. It will also support global manufacturers in complying with various languages and international standards, enhancing production efficiency across all markets.

We’re here to provide you with more details.

Reach out today!

How Direct Laser Part Marking Improves Automotive Safety

The automotive industry produced 1.8 million vehicles on US soil in 2022 and 85 million around the world—imagine how many individual parts that is! Thousands of manufacturing facilities are responsible for each part, meaning that even cars with the same make and model have parts from different facilities.

This ongoing flow of manufacturing is efficient for getting new vehicles on the market every year, but tracing every single part is not simple. The sheer volume of moving parts throughout the manufacturing process is impossible to manage by only identifying the make and model of a vehicle.

Laser marking automotive parts improves the safety of vehicles because it strengthens traceability with precise and permanent marks. The effectiveness of a laser marker translates to identifying vehicle recalls at rapid and organized rates.

Permanency

Laser marking has become a preferred choice in the automotive industry, mainly for its permanency. For one, serial numbers, barcodes, and other part identification marks need to withstand some harsh conditions. This includes exposure to extreme temperatures, chemicals, and abrasion. Unlike other methods, laser marking ensures that these types of marks remain intact and legible over the vehicle’s lifespan.

In addition, the permanency of laser marking is crucial for traceability and quality control in automotive manufacturing. These markings allow for accurate tracking of components through the production process and lifespan of the vehicle. This helps with quality assurance, recalls, and even compliance with industry regulations.

Alternative methods for laser marking automotive parts are ink, sticker labels, and chemical etching. However, these do not provide the permanency that is required for automotive uses and also require consumables.

Precision

As part of automotive manufacturing and assembly, having a precise marking method is important. Laser marking provides this precision and accuracy, allowing for intricate and fine details to be added to small auto components and delicate surfaces. Its tight tolerances also ensure that markings are placed exactly where they are intended without damaging surrounding materials.

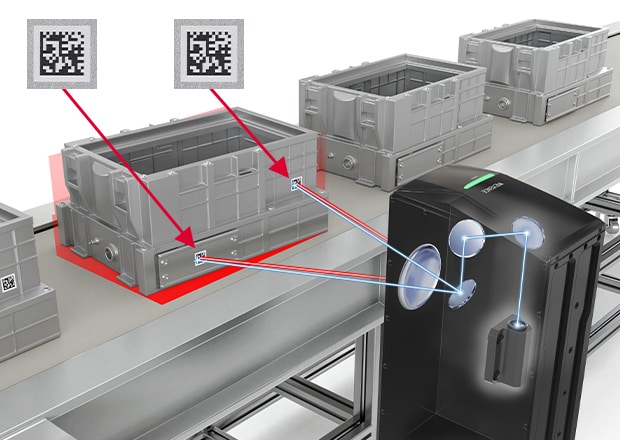

2D Code Quality Control

The largest obstacle to managing and tracing parts with 2D codes is ensuring that the codes are readable. KEYENCE laser markers allow operators to perform a two-way quality check for every mark. A built-in thermopile power monitor allows users to measure (with actual values) the power output of the laser while marking is performed. A built-in 2D code reader makes it possible to visualize the ability/inability of reading and overall reading reliability. These two check mechanisms make it possible to ensure high-quality 2D codes.

- Stable marking quality

- Improved yield

- Preventative maintenance

- Stable equipment operation

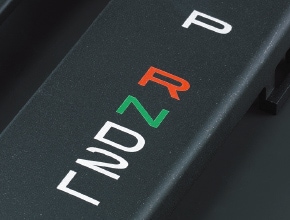

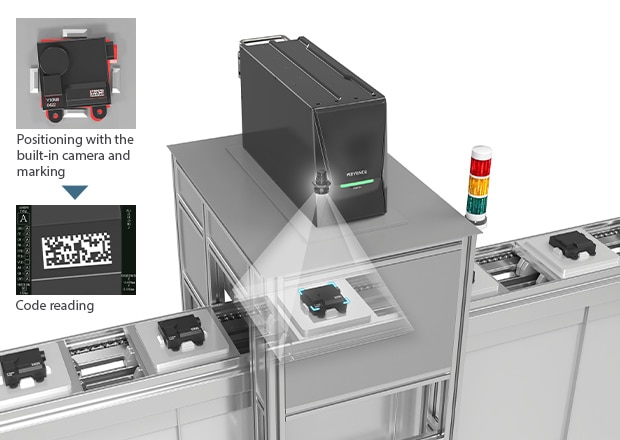

Auto-focus Feature

Large parts (like engine blocks) are difficult to align with the focal distance of a laser marker while being transported. This often results in focal misalignment, which in turn causes improper marking. 3-Axis laser markers allow you to perform auto-focused marking that can automatically adjust for changes in the focal distance. This eliminates the need for complicated transportation mechanisms and achieves high-quality marking that's always in focus. This feature is most effective in cases where stable quality is demanded, such as 2D code marking.

- Stable marking quality

- Simplifies equipment

- Increased processing speed

- Energy-efficient operation

Simplified Product Change-Over

There are an increasing number of cases in which multiple product types are manufactured with a single die-cast machine. In the past, these machines have had to be retooled to accommodate laser markers (due to their fixed focal distances). With a 3-Axis control laser marker, it is possible to design a flexible setup that supports multiple product types with a single box. Registering the size of the target and area that will be marked makes it possible to switch between product types by just changing the setting number.

- Reduced man-hours for operation

- Simplifies equipment

- Increased processing speed

- Stable marking quality

As you see, automotive laser marking has become an essential tool for automakers, and it shows no signs of slowing down. With more parts on both traditional and electric vehicles requiring marking, having reliable systems and procedures will allow for safe, timely, and efficient operations.

In addition to laser marking automotive parts, we offer a myriad of solutions for industry challenges. We have helped provide:

- Coolant flow control for metalworking machines

- Stamping-based product difference checking

- Crankshaft difference inspection

- Motor core lamination thickness measurement

- Scratch inspections of gears, bushing, and similar objects

- Post-encapsulation inspection for welding bead defects

- Body sealer dispense inspection

- Robot picking of metal parts and batteries

- Connecting rod measurement

- Battery lamination layer alignment

- Appearance inspection of battery housing

- U-pin dimension inspection

- Character recognition for inscriptions on casted parts

- Retaining ring detection

- ECU PCB solder inspection

- Connector terminal bend inspection

- Lithium-ion battery sealing plate top surface welding inspection

- Measurement of large castings and additionally processed components

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Application Video

FAQs about Laser Marking in the Automotive Industry

Which type of laser is used in the auto manufacturing industry?

Lasers of the infrared wavelength are the industry standard for component marking and processing. Commonly known as fiber lasers, these systems excel at working with metals and present high throughput capabilities appealing to auto manufacturing operations. There is a distinction to be made between marking, welding, and cutting lasers, all of which have their place in the automotive realm. Contact your local specialist to understand how the KEYENCE solution may work for you.

How are lasers used in the automotive industry?

Lasers are used for marking (Traceability, Compliance, Branding), Cutting, and Welding. From raw material to the final assembled components, lasers have the opportunity to facilitate the production process of your components.

What types of laser marking are used in the automotive industry?

The types of automotive laser marking used for vehicle parts are engraving, etching, and annealing.

What is laser engraving?

Laser engraving is a laser part marking process that vaporizes a target design and leaves behind an indented mark.

What is laser etching?

Laser etching is a laser part marking process that is best suited for high speed applications. The laser beam alters the target surface reflectivity to produce a contrasted mark.

What is laser annealing?

Laser annealing is a laser part marking process that rearranges a target’s atoms and leaves behind a dark mark without a texture.

Which automotive parts are laser marked?

Parts critical to the end performance of a vehicle are often laser marked to ensure the durability of the tracking and traceability information. Engine, airbag, and axial component manufacturers tend to seek the superior marking permanence provided by laser marking. Brake companies will utilize the flexibility of marking presented by lasers to build brand awareness through marking logos.

Can automotive plastics be laser marked?

Automotive plastics are being laser marked with increased frequency. Developments in the realm of laser marking, such as UV laser systems, have opened the door to working with automotive plastics without the need for material additives. For insight on how KEYENCE's laser marking solutions could work for you, please contact your local representative to learn more.

Why do I need a UV laser for plastic?

A fiber laser’s power may be too strong and distort your part. This is because plastic generally has a weaker heat resistance than metals.

Instead, a UV laser uses a marking method called “cold marking”, which does not have any heat transfer. The cold marking method is gentler on heat-sensitive materials like plastic.

How does laser marking enhance traceability in the automotive industry?

Laser marking in car manufacturing engraves permanent serial numbers, barcodes, and QR codes on automotive components. All markings withstand extreme conditions, ensuring that parts can be traced throughout their lifetime, which helps with quality control, recalls, and regulatory compliance.

Is laser marking suitable for all automotive components?

Yes, laser marking is extremely versatile and can be applied to metals, plastics, ceramics, and coated materials found in automotive parts. However, the suitability depends on material type, surface finish, and marking depth requirements. Adjusting laser parameters ensures clear, durable marks without damaging the integrity of delicate components.

How does laser marking improve counterfeit prevention in automotive parts?

Laser marking generates unique, tamper-resistant identifiers that are difficult to duplicate. These markings identify genuine parts and help manufacturers and suppliers prevent counterfeiting, warranty fraud, and unauthorized distribution.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.

2D codes have become a near-universal standard for traceability. This must-read document covers everything from code scanning principles, laser installation, predictive maintenance, and more.

2D codes are used to store date codes, lot codes, serial numbers, and more. Users who are considering 2D code marking should read this laser marking guidebook.

Some laser marking applications require integration with multiple devices. KEYENCE provides a total marking solution, from X/Y stages and indexing systems to head traversal systems. Learn more in this brochure.

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.