Industrial Laser Marking Systems / Laser Markers

Laser Etching vs Laser Engraving vs Laser Marking: Which to Choose?

-

Tags:

- Laser Engraving , Laser Etching , Laser Marking

Laser etching and laser engraving are commonly thought of as interchangeable, but there is a difference between the two when it comes to their processes and results. Laser etching and laser engraving both have benefits and drawbacks depending on the project’s desired outcome.

The process of laser marking involves altering the appearance of a material's surface. Laser marking machine technology is ideal for bar codes, QR codes, data matrices, and logos, to name a few.

With that said, it is essential to understand the difference between laser etching vs laser marking vs laser engraving to ensure you choose the best option for your particular needs. In the following, we’ll take a look at each process, along with the top industries that utilize them.

What is Laser Engraving?

What is a laser engraver, and how does it work? Laser engraving uses focused light to remove material, creating permanent, deep marks. Unlike other methods, it physically removes layers of material, making recessed designs that stay visible even in tough conditions. The depth (usually between 0.254 mm 0.01″ to 1.905 mm 0.075″, depending on the material) makes it perfect for things that need lasting identification, like industrial parts.

Today's laser engraving systems give users great control over how deep the patterns go, allowing for detailed designs with different depths in a single project. This flexibility has changed personalization in many industries, from marking aerospace components to creating custom consumer products.

We’re here to provide you with more details.

Reach out today!

How Laser Engraving Works

Laser engraving works by vaporizing material. The system focuses intense light on a specific spot, heating the material so quickly that it turns directly from solid to gas, leaving a cavity behind. The laser follows computer-programmed paths to create precise patterns.

The system has three main parts working together: the laser source (such as diodes or CO2 chambers), a controller that stores and delivers files (the brains), and a platform that holds the material. Advanced systems use special mirrors (galvos) that move the beam quickly according to the design, creating detailed patterns at high speeds. The computer controls the whole process, ensuring every item comes out identical, with microscopic precision.

Differences Between Laser Etching vs Laser Engraving vs Laser Marking

The full scope of this topic can get pretty convoluted, so it can help to compare engraving vs etching side by side. In the table below, notice the several key differences between laser engraving, etching, and marking.

| Topic | Laser Etching | Laser Engraving | Laser Marking |

|---|---|---|---|

|

Applications

|

Laser Etching

Marks on polymers, metals, and ceramics.

|

Laser Engraving

Logos, serial numbers, and personalization.

|

Laser Marking

Logos, barcodes, UID codes.

|

|

Alteration

|

Laser Etching

Methods of melting and material expansion.

|

Laser Engraving

Pulse vaporization of material.

|

Laser Marking

Discoloration of material surface.

|

|

Core Process

|

Laser Etching

Melts surface material with heat.

|

Laser Engraving

Physically removes material from the surface of the item.

|

Laser Marking

Uses the beam to alter the surface with high contrast and low (to no) damage.

|

|

Strong suit

|

Laser Etching

Boosts visual contrast and reflectiveness.

|

Laser Engraving

Utilized for depth requirements or customizing personal items.

|

Laser Marking

A go-to option for effective and efficient part and product identification.

|

There are many differences between these terms, each with a unique use case that continues to be used across many industries. However, it is understandable to compare laser engraving vs etching and marking and wonder why there’s a need for so many variations.

Top Benefits of Laser Engraving

In terms of etching vs laser engraving, engraving offers incredible precision that traditional methods can't match. The laser beam can be as thin as 0.0254 millimeters 0.001 inches, creating tiny details and text that remain readable even at miniature sizes—perfect for medical devices and electronics.

Since lasers never touch the material, there's no mechanical stress that might warp or damage delicate items. This makes laser engraving ideal for thin materials that traditional methods might damage. Modern systems also let users adjust settings like power, speed, and focus to work perfectly with different materials without changing equipment.

Materials Commonly Used in Laser Engraving

Metals are frequently engraved, and stainless steel, aluminum, brass, and titanium work especially well. Different lasers suit different metal surfaces—fiber lasers work best on bare metals, while CO2 lasers are better for coated metals. The marks can range from deep cuts to dark surface marks, depending on what's needed.

Wood creates beautiful results when laser-engraved, with each type of wood producing a unique look. Hardwoods like maple, cherry, and walnut create clean lines with minimal burning, while softwoods might need different settings. The natural wood grain creates unique patterns when engraved.

Plastics and acrylics also work well with laser engraving, though results vary by type. Acrylic typically shows white frost-like engravings, while other plastics may need specific laser types for good contrast. Specialty plastics with glass or carbon fiber can be challenging and require careful adjustments.

Discover more about this product.

Click here to book your demo.

Laser Etching Process

Laser etching creates raised marks on metal material, such as aluminum, stainless steel, or zinc by electrolyte absorption. The laser etching process begins with a laser beam hitting and electrifying a metal, resulting in a current running through it. The metal then partially absorbs the energy and also reflects the energy.

Once the metal absorbs the energy and transforms it into heat, the metal becomes malleable, expands, and changes in color and texture. The ratio of absorption to reflection affects whether the etch will be black, white, or gray. You may choose laser etching vs laser engraving vs laser marking for the stylistic reason of wanting raised marks instead of deep or even high contrast marks or because the process is generally faster.

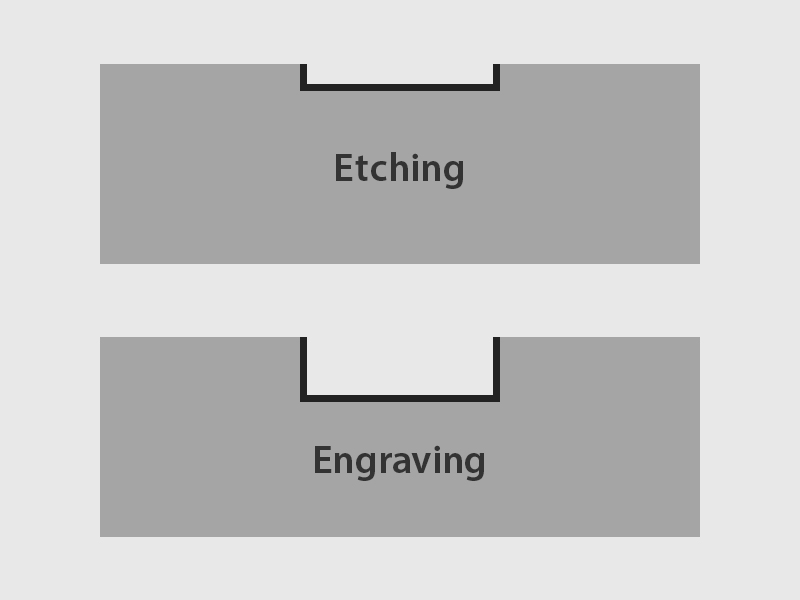

Laser Engraving Process vs the Laser Etching Process

Laser etching vs engraving are both techniques used to create designs, but they differ in how they interact with materials and the range of materials they can be applied to. Laser engraving involves vaporizing the material, allowing for deep marks on metal, wood, or plastic.

On the other hand, laser etching makes the material malleable and causes expansion upon laser contact. When durability is a priority and the product must withstand environmental conditions, deep laser engraving is recommended to achieve deep, long-lasting marks. However, if the original material strength and rigidity must be preserved, laser etching becomes the preferred choice.

Laser Engraver Types and Applications

Fiber laser engravers are best for metals, creating precise marks on items like surgical tools and car parts. These powerful machines work continuously in factories and can create tiny, detailed markings that last.

CO2 laser engravers work well with natural materials like wood, leather, and glass. They're commonly used for signs, awards, and custom products. CO2 laser engravers are great for organic materials, so are commonly used in more textile or custom design applications.

Diode laser engravers are more affordable options for hobbyists. Though not as powerful as industrial machines, these compact systems work well for lighter projects on various materials. Their smaller size and improved technology have made laser engraving accessible for home crafters and small customization businesses.

Laser Marking Process

Commonly referred to as discoloration, the laser marker process moves slowly across a surface for a high contrast result. One favorable characteristic of this process is that the marking can be applied with little to no damage, depending on the laser medium used.

The heat from the laser creates black marks through oxidation, or it can also apply less concentrated heat to anneal the surface. Regardless of the approach and the differences between laser marking and engraving, this process has helped manufacturers speed up operations.

We’re here to provide you with more details.

Reach out today!

Laser Etching and Laser Engraving for Part Traceability

Although there is a difference between laser etching vs engraving, they both are essential for part traceability because of their permanence. Tracing parts, tools, or jigs through a plant or supply chain is necessary for an efficient recall, minimizing damages, extracting and improving management challenges, and ensuring quality management.

There are two types of part traceability—chain traceability and internal traceability. Both of these use etching and engraving for success. Chain traceability traces a part’s progress from raw material to sale, whereas internal traceability tracks parts along the supply chain through a single company or plant.

For traceability, a tool, jig, or product is laser etched or laser engraved with a serial number that correlates with a description of the tool, such as usage, wear limits, plant names, shelf numbers, count, and date or time. Without traceability, a company may struggle with efficiency when attempting to recall or investigate an issue with a product.

Additionally, traceability allows consumers to feel confident in the reliability of their product because they know where their product came from. Although part traceability relates to tools, many industries use this practice for other products.

How Can Laser Markers Be Integrated?

A common gripe with conventional etching tools is the inefficiency of creating new designs. Since chemical etching tools may use a stencil, creating designs takes time, money, and additional materials. Instead of a physical stencil, laser markers simplify this process by reading and imitating programming based on data loaded from a CAD file.

Chemical etching is generally used for engraving or eliminating resin, but the process can be detrimental to the product because of its harsh nature. Laser markers are a great alternative since the laser produces the same result in a more efficient and consistent manner.

Sometimes, the deep cut of engraving is desired for a product, but roadblocks like difficulty engraving small characters and rough or curved surfaces can arise from using a conventional engraver. Additionally, conventional engraving machines can add stress to the material and be a tedious process, so using a laser marker rather than a hand-scribe or dot-peen is more efficient and gentle on materials.

Laser markers can also generate characters smaller than 1mm and mark on rough surfaces. Although some laser markers need external equipment to mark curved surfaces, certain laser markers have this capability built in. This flexibility is especially beneficial in the automotive industry. As an example, many parts have identification numbers laser marked in them, making part tracing simple and efficient.

Why Do Manufacturers Need Laser Etching, Laser Engraving, and Laser Marking?

Considering laser marking vs laser engraving and etching from a global viewpoint, there are many apparent use cases across numerous industries.

Some of this comes down to regulation, while other angles focus on a necessary approach based on the type of materials that are involved. The list below provides a comprehensive look at why a laser marker for engraving, etching, and other applications is so vital.

- Regulation: Being able to resort to different benefits of laser marking can help manufacturers abide by a wide variety of product ID laws and regulations.

- Promised Durability: They are known to be highly resilient to external wear and easily outlast the capabilities of industrial inkjet printers.

- Efficiency: It continues to be proven that laser engraving applications and similar methods are much more efficient than traditional inkjet. The technology also helps mitigate human error and improve consistency from one item to the next.

- Eco-friendly: In our modern era, the manufacturing industry as a whole is in need of more eco-conscious solutions. This is another upside to laser technology over traditional options that can help reduce waste significantly.

Manufacturing technology is always evolving, and laser processes are becoming a prominent choice. The global manufacturing industry is recognizing the benefits of lasers and how they help them stay competitive as these shifts occur. In short, manufacturers will continue to utilize laser etching, marking, and engraving to meet regulatory requirements, create durable and traceable marks, and improve efficiency.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can laser engraving be used for traceability on metals?

Yes, laser engraving works great for tracking metal parts and creating permanent marks that survive tough industrial conditions. The deep marks stay readable even after surface wear, making them perfect for identifying parts in aerospace, automotive, and medical manufacturing.

How deep can laser engraving go compared to etching?

Laser engraving reaches depths of 0.254 mm 0.01″ to 1.905 mm 0.075″, depending on the material, while etching only reaches depths of 0.0254 mm 0.001″ to 0.127 mm 0.005″. This makes engraving better for applications needing durability in harsh conditions, while etching is better when you need to preserve the material's strength.

Is laser engraving more durable than printed markings?

Laser engraving is much more durable than printing, resisting scratches, chemicals, and weather that would quickly damage ink. Unlike printed labels that fade or peel off, laser-engraved marks become part of the material itself, staying readable throughout the product's life.

Can you laser engrave any material?

While many materials work well, some, such as PVC, Teflon, and certain compositions of plastic, release toxic fumes when engraved and should be avoided or engraved carefully with proper fume extraction. Shiny metals may need special laser types, and materials with low melting points can melt rather than engrave cleanly.

Is laser engraving permanent?

Laser engraving is permanent because it physically removes material, creating marks that can't be removed without significantly altering the surface. The depth ensures marks stay visible even after years of wear, though very thick coatings applied afterward might slightly reduce visibility.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.

Choosing the right laser marker wavelength is extremely important for plastic marking. Learn what lasers work best for marking, processing, and coloring plastic in this guide.

2D codes have become a near-universal standard for traceability. This must-read document covers everything from code scanning principles, laser installation, predictive maintenance, and more.

2D codes are used to store date codes, lot codes, serial numbers, and more. Users who are considering 2D code marking should read this laser marking guidebook.

Some laser marking applications require integration with multiple devices. KEYENCE provides a total marking solution, from X/Y stages and indexing systems to head traversal systems. Learn more in this brochure.

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.