Industrial Laser Marking Systems / Laser Markers

Fiber vs. CO2 vs. UV: Which Laser Marker Should I Choose?

-

Tags:

- Laser Marking , Laser Etching , Laser Cleaning

Lasers can mark and process a wide variety of products, but there's no one-size-fits-all answer for every application. Fiber, CO2 and UV laser markers perform differently depending on the application and material.

Here's a brief overview of Fiber, CO2 and UV laser technology. We've also included some sample marking videos that highlight the strengths and weaknesses of each system.

Overview of Fiber, CO2, and UV Laser Technologies

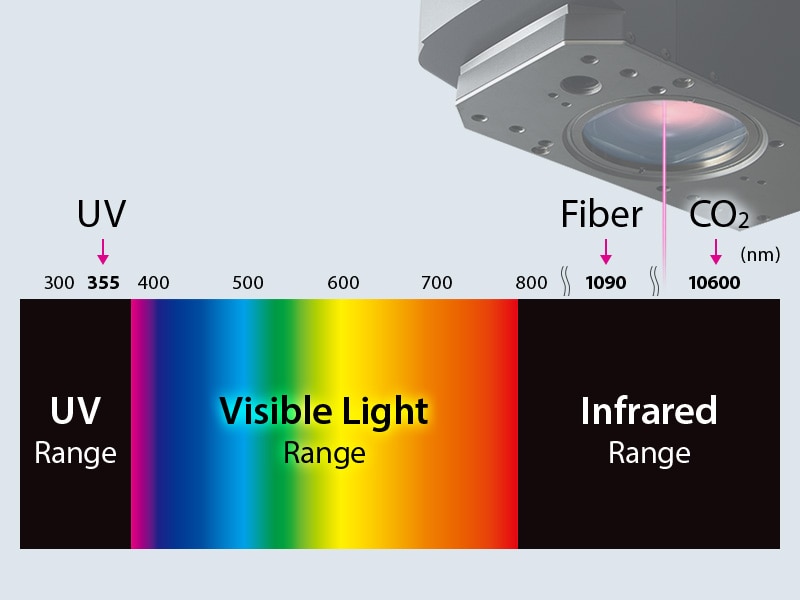

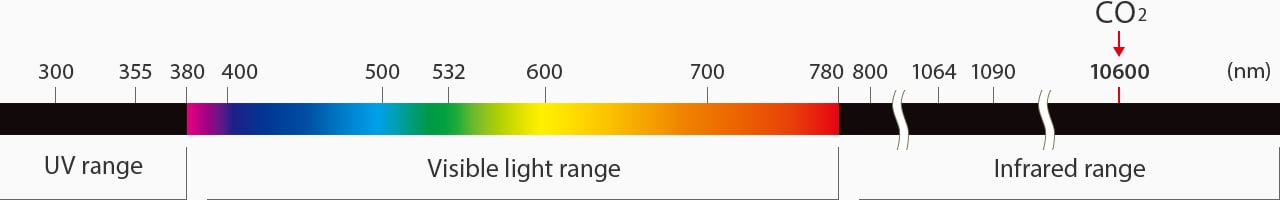

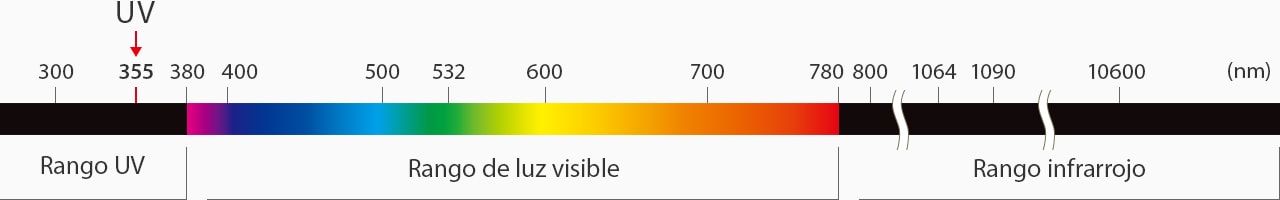

The most important difference between fiber laser vs CO2 laser and UV laser markers is the wavelength of light they produce.

Short wavelengths typically have more energy and a higher absorption rate than long wavelengths. As a result, a laser's wavelength affects its ability to mark certain materials.

Fiber laser systems use infrared light to create precise marks on materials. These systems generate high power levels through optical fibers that amplify light energy. The wavelength makes them ideal for absorbing into metals and creating permanent marks.

CO2 laser technology uses a gas mixture to produce the laser beam. Their longer wavelength allows excellent absorption into organic materials like wood and plastic. UV laser vs fiber laser (and CO2) systems work a bit differently, creating what's called "cold marking" because their absorption is so high they do not rely on heat to generate the mark.

The features of and marking examples for the different wavelength types are introduced below.

Light wavelength distribution map

* More Fiber vs. CO2 vs. UV comparison videos towards the bottom.

How Each Laser Type Works

Fiber lasers pump light through rare-earth elements in glass fibers to create the beam. The process builds energy as light travels through the fiber, creating intense infrared radiation. This wavelength penetrates metal surfaces and creates chemical reactions that form permanent marks.

A CO2 engraver mixes carbon dioxide gas with nitrogen and helium in a sealed tube. Electric current excites the gas mixture, producing infrared light that gets focused through mirrors. UV lasers use crystals to convert infrared light into ultraviolet radiation through a process called frequency tripling, which creates the short wavelength needed for precise work.

We’re here to provide you with more details.

Reach out today!

What are Fiber Lasers?

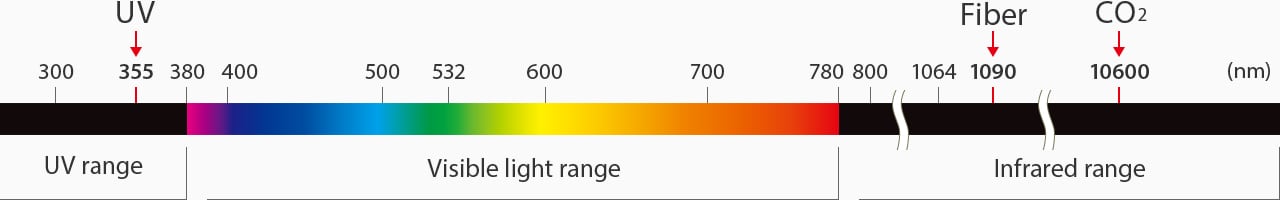

Fiber lasers have a 1090 nm wavelength, making them IR (infrared) lasers. Fiber lasers can mark a wide range of materials, though they are optimized for metal marking applications. Their high power makes them perfect for annealing and engraving applications, but they cannot mark transparent objects since IR light passes straight through.

Light wavelength distribution map

Engraving (Painting After Marking)

Vehicle body frame

Black-Annealed Marking

Bearing

High-Speed 2D Code Marking

Engine block

Etching

Key cylinder

Laser Cutting

Aluminum board

Burr Removal

Frame IC

Get detailed information on our products by downloading our catalog.

View Catalog

What are CO2 Lasers?

Light wavelength distribution map

Cartons

Bottles

Design marking

Glass wafers

Weatherstripping

Electronic PCBs

Get detailed information on our products by downloading our catalog.

View Catalog

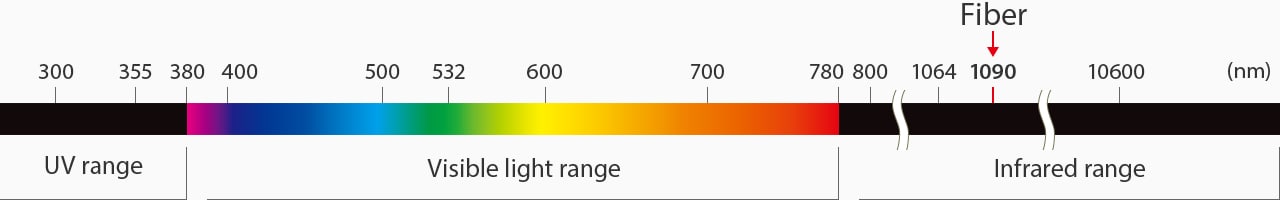

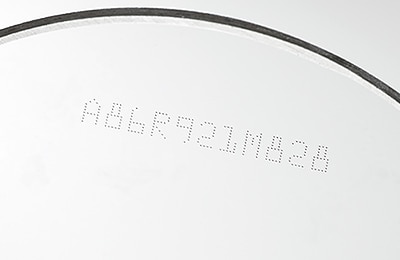

What are UV Lasers?

UV lasers use a highly absorbable wavelength (355 nm) to mark parts. This high absorption rate allows UV lasers to perform "cold marking" (i.e. marking without extra heat stress). As a result, UV lasers are ideal for applications that require high-contrast or minimal product damage.

Light wavelength distribution map

Multicolor automotive relays

Earbuds

Chemical bottles

Copper lead frames

Steel tools (scissors, etc.)

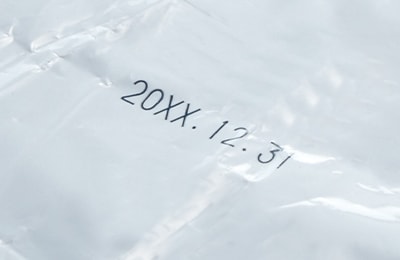

Food packaging film

Get detailed information on our products by downloading our catalog.

View Catalog

Typical Use Cases and Materials

Fiber laser systems excel at marking stainless steel, aluminum, and titanium parts in automotive manufacturing. These systems handle high-volume production lines where speed matters most. CO2 lasers work best on cardboard packaging, acrylic displays, and wooden furniture where organic materials need processing.

UV laser technology shines when marking delicate electronics, medical devices, and pharmaceutical packaging. The cold marking process prevents heat damage to sensitive components. Fiber systems also handle tool marking, while CO2 lasers cut through thick materials that other systems cannot process effectively.

Best Lasers for Metals

Fiber laser systems dominate metal marking applications. The infrared wavelength penetrates steel, aluminum, and brass surfaces efficiently. These systems create annealed marks, etched patterns, and deep engravings that survive harsh environments.

UV lasers can also mark metals and even highly reflective metals that fiber lasers can't, like copper, silver, or gold. However, fiber systems typically provide faster processing speeds for most metal applications. CO2 lasers cannot mark metals effectively because the long wavelength reflects off metallic surfaces instead of being absorbed.

Best Lasers for Plastics and Glass

UV laser technology excels at marking plastic materials without causing heat damage or melting. The short wavelength creates clean, precise marks on polymers, resins, and flexible films. These systems prevent the thermal stress that other laser types might cause.

CO2 lasers work well on certain plastics and excel at glass marking applications. The longer wavelength creates frosted effects on glass surfaces through controlled heating. Fiber lasers struggle with transparent materials because infrared light passes through without being absorbed effectively.

Discover more about this product.

Click here to book your demo.

Fiber, CO2, and UV Laser Marking Comparison

These videos compare fiber laser vs CO2 laser and UV laser marks on different materials.

Fiber vs. CO2 vs. UV Marking on Metal (Iron)

- Fiber Laser: Highly visible marking is possible

- CO2 Laser: Marking isn't possible because iron doesn't absorb CO2 laser light

- UV Laser: Damage-free marking is possible but the contrast is low (compared to the fiber laser mark)

Fiber vs. CO2 vs. UV Marking on Metal (Copper)

- Fiber Laser: Marking may not be possible because copper is highly reflective and doesn't easily absorb Fiber laser light

- CO2 Laser: Marking isn't possible because copper doesn't absorb CO2 laser light

- UV Laser: High-contrast, damage-free marking is possible because copper easily absorbs UV laser wavelength light

Fiber vs. CO2 vs. UV Marking on Resin (PE)

- Fiber Laser: Fiber laser light reacts with the pigments in the resin to produce high-contrast marks

- CO2 Laser: CO2 laser light creates non-contrast marks and causes the resin's surface to swell

- UV Laser: UV laser light reacts with the pigments in the resin to produce high-contrast, damage-free marks

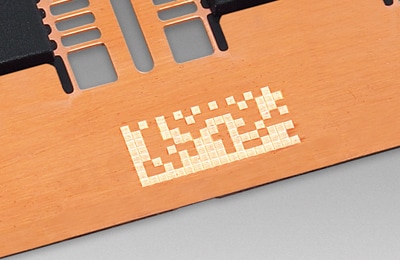

Fiber vs. CO2 vs. UV Marking on Cartons

- Fiber Laser: Marking isn't possible because the carton doesn't absorb Fiber laser light

- CO2 Laser: CO2 laser light burns the surface of the carton to produce marks

- UV Laser: The paper on the carton absorbs UV laser light, resulting in high-contrast marks

Fiber vs. CO2 vs. UV Marking on Transparent Targets (POM)

- Fiber Laser: Marking isn't possible because clear plastic doesn't absorb Fiber laser light

- CO2 Laser: CO2 light uses heat to produce marks

- UV Laser: Marking may not be possible because clear plastic (POM) doesn't absorb enough UV laser light

Fiber vs. CO2 vs. UV Marking on Pouches

- Fiber Laser: Fiber laser light is not easily absorbed and damages the pouch

- CO2 Laser: CO2 laser light creates marks by burning off the pouch's surface

- UV Laser: UV laser light reacts with the film on top of the pouch to produce high-contrast, damage-free marks

We’re here to provide you with more details.

Reach out today!

Final Marking Results

Fiber lasers can quickly mark the widest range of materials and typically produce the most contrast on metals. However, fiber lasers cannot mark transparent materials and will sometimes damage the marking surface.

UV lasers provide the most contrast on resins. UV lasers have the added benefit of creating damage-free marks.

CO2 lasers burn the target with heat, making them ideal for marking wood, paper, ceramic and transparent targets.

| Fiber Laser | CO2 Laser | UV Laser | |

|---|---|---|---|

|

Metal (Iron)

|

Fiber Laser

High visibility

|

CO2 Laser

Low visibility

|

UV Laser

Low visibility

|

|

Metal (Copper)

|

Fiber Laser

Low visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

|

Resin (PE)

|

Fiber Laser

High visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

|

Cartons

|

Fiber Laser

Low visibility

|

CO2 Laser

High visibility

|

UV Laser

High visibility

|

|

Transparent Targets

|

Fiber Laser

Low visibility

|

CO2 Laser

High visibility

|

UV Laser

Low visibility

|

|

Pouches

|

Fiber Laser

Low visibility

|

CO2 Laser

Low visibility

|

UV Laser

High visibility

|

* Results may vary depending on the material and its status. The above results only represent an example.

Applications of Fiber, CO2, and UV Laser Markers in Different Industries

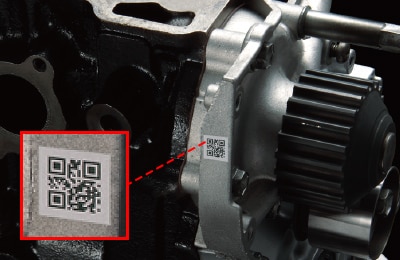

Laser marking, whether it is fiber laser vs CO2 laser or UV-driven, is used widely for many applications. Each has its own advantages depending on the material and production needs. Fiber lasers, for example, are ideal for marking on metals in the automotive industry, such as engraving serial numbers on engine parts or for deep marking aerospace components like titanium bolts. Electronic manufacturers use them as well to mark circuit boards and metal connectors.

CO2 lasers excel at coding expiration dates on food packaging, engraving branding on glass beverage bottles, or cutting intricate designs into wooden furniture. UV lasers are ideal for producing high-contrast markings on silicon wafers used in electronics manufacturing, engraving precise codes on medical devices without causing damage to plastic surfaces, and marking logos on cosmetic containers.

How to Choose Between Fiber Laser vs CO2 vs UV for Your Production Line

When selecting between a UV, fiber laser vs CO2 laser marking applications for your production line, the material type, required marking speed, and operational needs should be considered. Fiber laser machines use higher average powers and have powerful marking capabilities, making them ideal for metal and industrial applications. Being that these systems offer high-speed, deep engraving, achieving long-lasting results is possible.

On the other hand, CO2 lasers have a longer wavelength. Cutting and engraving non-metallic, organic materials such as glass, acrylic, and textiles is simplified, making them ideal for packaging and consumer goods industries. UV laser systems, however, use short-wavelength light. When high-precision marking is required on delicate materials like plastics, semiconductors, and medical devices, UV lasers are often a wise choice. No heat-related damage occurs to sensitive surfaces which may happen with other laser marking methods.

The good news is that regardless of your materials and industry requirements, there is a right-fit laser type available. Choosing the correct equipment optimizes production line efficiency, reducing downtime and speeding up operations.

How to Choose the Right Laser for Your Application

Every manufacturing environment is unique in its own right. Deciding between a fiber laser vs CO2 or UV lasers depends on understanding your manufacturing process, material requirements, and desired output quality. Facility layout, employee safety, and operational efficiency may influence decisions on what laser marking equipment works best. Fiber lasers, as an example, may require less maintenance and downtime, reducing strain on employees who are busy with other tasks.

Consider your primary material type first when selecting between fiber, CO2, or UV laser systems. Metal parts require fiber lasers for deep penetration and lasting marks. Organic materials like paper and wood respond better to CO2 laser energy.

CO2 lasers, which can be bulkier, might need specific space considerations, ensuring both the facility and workforce can handle the equipment’s demands. UV lasers, with their precision and minimal heat, may be favored in environments where sensitive materials and worker safety are prioritized. Manufacturing includes many moving parts. By carefully weighing these factors, you can smoothly integrate new equipment and improve overall productivity.

Production speed also influences your choice. Fiber lasers handle high-speed operations with minimal maintenance needs. UV systems work slower but provide superior quality on delicate materials. CO2 lasers offer excellent versatility across non-metal materials.

When the question comes up of whether fiber vs. CO2 laser or UV laser is best, we understand that you still may have questions. KEYENCE offers a versatile range of laser markers designed to meet your specific needs. Contact us today to speak with a specialist or receive a product demo.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

Can I use the same laser marker for both metals and plastics?

Most laser systems work best with specific material types rather than being universal solutions. UV lasers can handle both materials effectively, while fiber lasers excel at metals but struggle with plastics.

What is the typical lifespan of each type of laser marker?

Fiber lasers last 100,000+ hours, CO2 lasers need maintenance every 10,000-20,000 hours, and UV lasers provide 10,000-15,000 hours of service life. KEYENCE lasers excel when it comes to lifespan and are typically rated for 3 to 10 times longer than the standard, depending on the wavelength.

Is a UV laser safe to use around electronics?

UV lasers are specifically designed for electronics and pose minimal risk when proper safety protocols are followed.

Which laser is best for marking metal parts?

Fiber laser systems provide the best performance for most metal marking applications with excellent speed and quality.

Can CO2 lasers mark metal?

CO2 lasers cannot effectively mark metals because the long wavelength reflects off metallic surfaces instead of being absorbed.

Why are UV lasers better for marking plastics?

UV lasers have a shorter wavelength and thereby a higher absorption rate meaning that they are able to mark a larger variety of plastics, including different colored plastics.

How do I choose between a fiber, CO2, and UV laser for my business?

Choose based on your primary materials: fiber for metals, CO2 for organic materials, and UV for delicate materials requiring precision.

We’re here to provide you with more details.

Reach out today!

Related Downloads

This booklet covers a wide range of laser processing techniques - such as cutting, drilling, and deep engraving - as well as welding and soldering that are unique to lasers.

2D codes are used to store date codes, lot codes, serial numbers, and more. Users who are considering 2D code marking should read this laser marking guidebook.