Industrial Laser Marking Systems / Laser Markers

Fiber Laser Marking

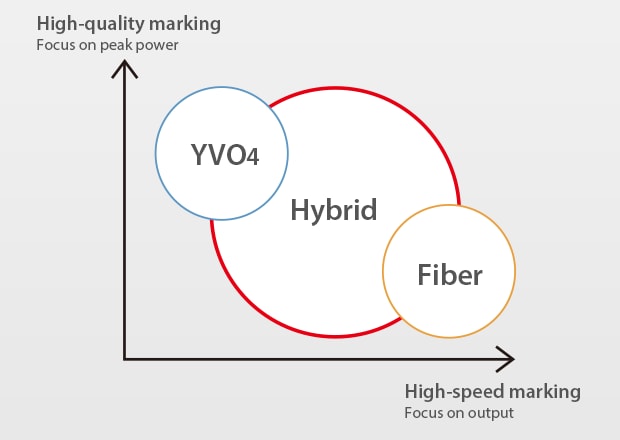

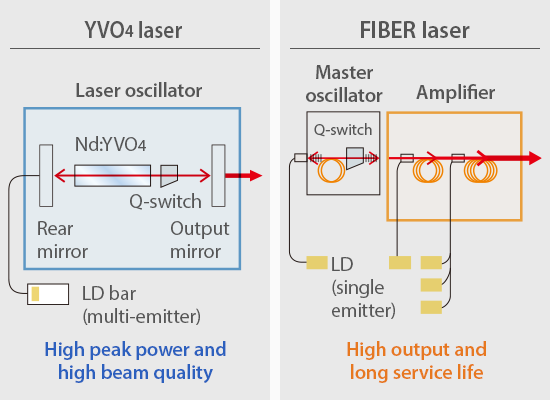

Fiber lasers are solid-state lasers known for their high output power, speed, and ability to deep engrave. Due to this high output power, fiber lasers specialize in engraving, marking, or etching metals at high speeds. However, fiber lasers are known for their heat affect, which can be detrimental when marking plastics or needing precision marks on metals. This is where hybrid laser markers excel, with a combination of fiber and YVO4 technology, hybrid lasers can generate high output powers for metals and high peak power for plastics.

What is a Fiber Laser?

Fiber laser markers have a 1090 nm wavelength, making them IR (infrared) lasers. Fiber lasers can mark a wide range of materials, though they are optimized for metal marking applications. Their high output power makes them perfect for deep engraving applications as well as any marking or processing application with tight cycle time requirements.

Fiber laser markers are actually based on the same technology used for long-distance communication (optical fibers). A laser is efficiently amplified when it travels through an optical fiber, making it possible to produce a high-output fiber laser.

We’re here to provide you with more details.

Reach out today!

The Advantages of Fiber Laser Marking

Why are so many industries using fiber laser marking as part of their operations? Although each use case is unique, manufacturers are benefitting in a number of ways. First, it provides non-contact, high-speed marking with extreme accuracy. As a result, reduced wear on parts and less risk of material distortion are achieved. Fiber laser marking machines stand out for their low maintenance costs and long operational life, reducing downtime.

Fast marking and deep engraving are possible due to the lasers high average power. For manufacturers, a fiber laser engraving machine is particularly advantageous for environments where high-volume production lines demand speed and efficiency. Businesses can avoid costly delays, as the technology of these machines ensures consistent performance, even under continuous use. Additionally, their ability to mark intricate designs, text, or codes in a single pass enhances both product traceability and branding efforts.

Applications of KEYENCE Fiber Laser Marking Machines

Now that we’ve gone over the benefits, let's look at specific applications that use fiber laser engravers from KEYENCE. In the automotive industry, they are essential because they mark engine parts, VIN codes, and component identifiers, making it possible to track each part throughout its lifecycle.

Aerospace industry manufacturers use these machines to precisely mark turbine blades, flight instruments, and safety equipment with information such as inspection marks or serial numbers in order to comply with regulatory requirements.

Fiber laser marking guarantees that parts like circuit boards and microchips are accurately marked with identifying numbers, QR codes, or other markings that can survive challenging conditions in the electronics industry.

Medical device manufacturing has many uses for fiber laser engraving machines. For instance, marking surgical tools and implants with UDI (Unique Device Identification) codes ensures full traceability while complying with FDA regulations.

In the energy sector, fiber laser marking is used to label and track components in renewable energy systems. For example, wind turbine parts and solar panel assemblies are marked with serial numbers, manufacturing dates, and maintenance information to ensure efficient monitoring and servicing. Reliability and efficiency of renewable energy sources are increased by the ease of maintenance and longevity of energy infrastructure.

Below are details on what a hybrid laser marker is and how it differs from the standard fiber laser marker.

Discover more about this product.

Click here to book your demo.

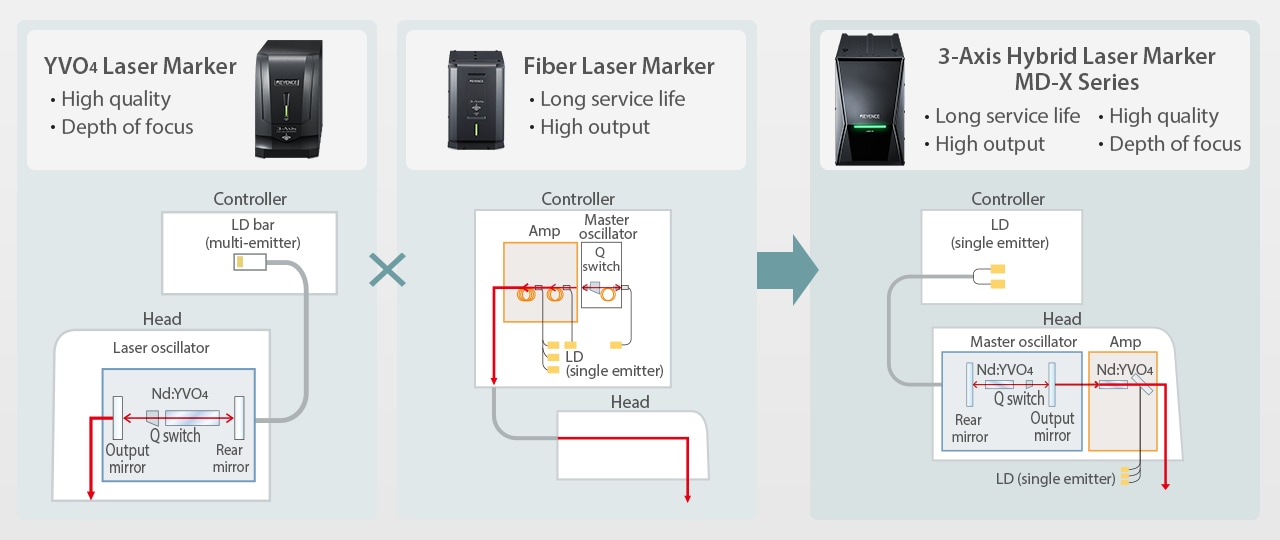

What is a Hybrid Laser Marker? - Fiber and YVO4

A Hybrid laser marker is a combination of a fiber laser and a YVO4 laser. Fiber lasers are known for their high average power, which is especially important for deep engraving or tight cycle times, while maintaining a long service life. YVO4 laser markers are known for their high beam quality, peak power, and versatility when it comes to marking a wide range of materials. The KEYENCE Hybrid laser has been designed to capitalize on the strengths of both of these laser markers. The built-in oscillator (S-MOPA) provides the advantages of both technologies giving the hybrid a high average power and longer service life, while also giving it the high beam quality, peak power, and overall versatility that the YVO4 laser provides. This makes the hybrid laser marker the most versatile and well rounded laser on the market.

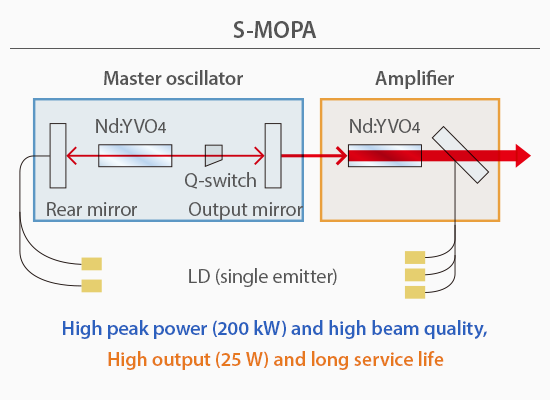

What is S-MOPA & Why is it Important?

Covers the advantages of conventional YVO4 laser markers and fiber laser markers (compared to the conventional KEYENCE model)

The KEYENCE S-MOPA (Solid-state Master Oscillator Power Amplifier) is a next-generation laser oscillation that combines the high quality and high intensity of YVO4 lasers with the long service life and excellent radiation characteristics of fiber lasers. One unique characteristic of the S-MOPA is its two-stage construction in which a YVO4 laser oscillator (master oscillator) is used to generate the pulse, which is then amplified by a YVO4 amplifier. This makes it possible to amplify the pulse generated by the master oscillator while maintaining the high peak power and high quality of the pulse.

Also, single-emitter pumping laser diodes - an advantage of fiber lasers - are used. This provides lower heat density than the multi-emitter laser diodes (laser diodes that have multiple light emitting surfaces in a single semiconductor chip) of solid state lasers. This enables the KEYENCE S-MOPA to have a long service life even while being a solid state laser.

We’re here to provide you with more details.

Reach out today!

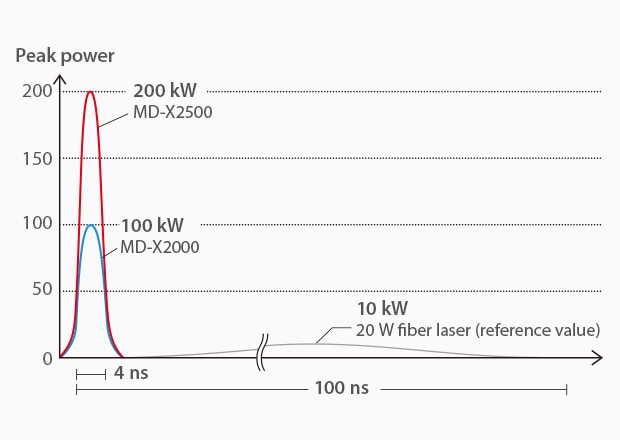

Peak Power: Fiber vs. Hybrid

The main difference between the hybrid and the fiber lasers are their peak powers and their pulse widths. Peak power is the intensity of the light and pulse width is the duration of light. Hybrid lasers have the characteristic of easily creating light with a high peak and short pulse, which they get from the YVO4 technology. Fiber lasers have the characteristic of easily creating light with a low peak and long pulse. When subjecting materials to a laser, the processing results vary greatly depending on the pulse differences.

The high peak and short pulse allow the light to have a better reaction with the material with very limited heat effect. This leads to the ability to mark a wider range of materials, especially heat sensitive metals and plastics, with high contrast and much less heat effect. The low peak and long pulse leads to a lot more heat effect on the marked materials, making it much more difficult to mark plastics or heat sensitive material without burning or charring. On the other hand, the low peak and long pulse allows for deep engraving or digging into harder materials with faster cycle times than its counterpart.

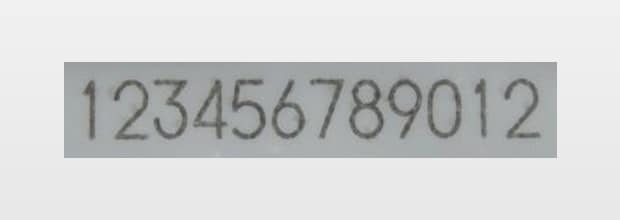

Contrast Marking on White Resin

YVO4 laser

Fiber laser

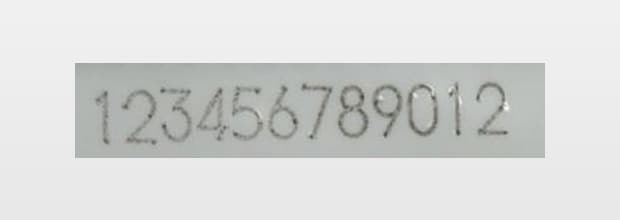

Nickel-Plated Marking

YVO4 laser

Fiber laser

SUS Engraving

YVO4 laser

Fiber laser

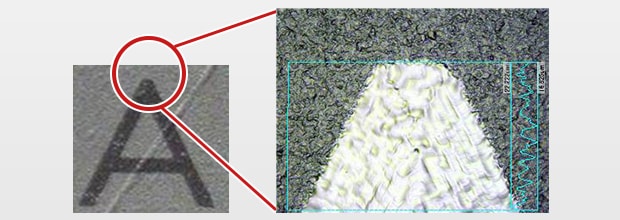

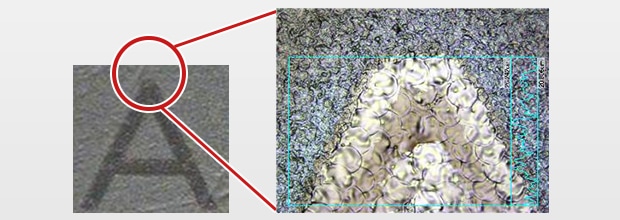

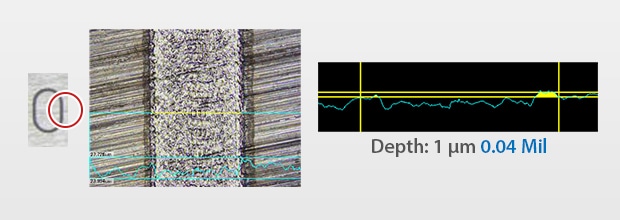

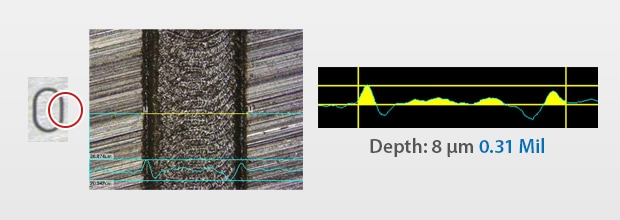

Beam Quality: Fiber vs. Hybrid

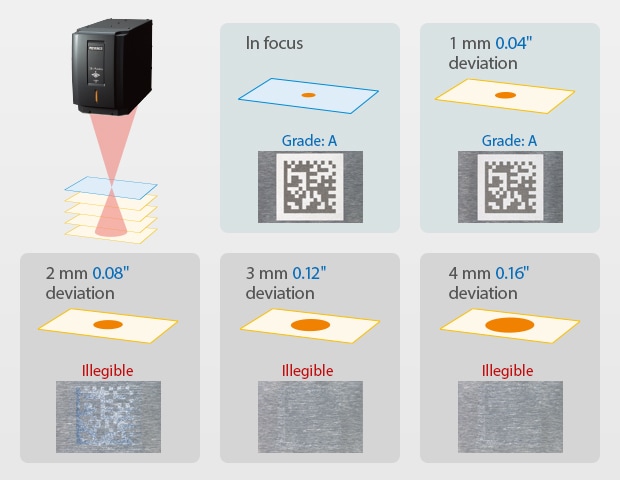

The beam quality of a laser marker is extremely important because it can determine the energy concentration and overall effectiveness of the laser. The quality of a beam is measured with a M2 value, the closer this value is to 1 the higher the quality of the beam. This is also one of the differences between hybrid and fiber laser markers. The YVO4 oscillator in the hybrid laser generates a beam with an M2 value less than 1.3, which is significantly better than the fiber standard around 2.

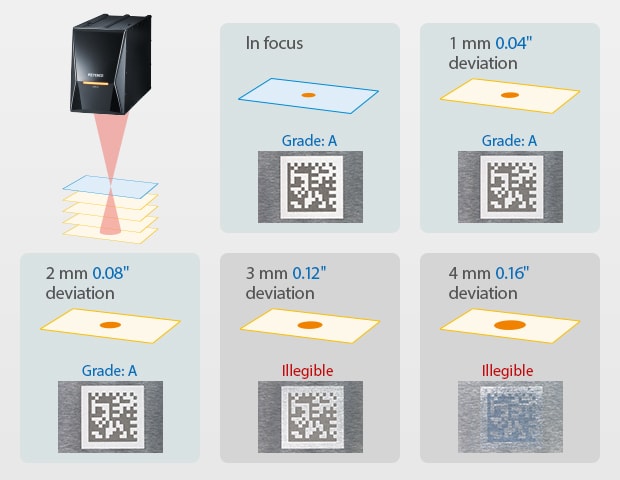

The reason that this is important is the better the beam quality the more consistent the mark and the greater the depth of focus. Depth of focus is an important factor for basic performance in order to achieve and maintain marking quality. When used in combination with the Z tracking function, this also results in a very high tolerance to height deviation, one of the most common concerns or issues with laser marking in general.

KEYENCE Fiber Laser Marker

MD-X Series

Curious about our pricing?

Click here to find out more.

Marking Versatility: All Laser Comparison

The combination of fiber technology and YVO4 technology makes the hybrid laser one of the most, if not the most, versatile lasers on the market. With S-MOPA, high peak power, short pulse duration, and high beam quality the hybrid laser can mark almost every material. Below shows the comparison of how well UV, Green, Hybrid, Fiber, and CO2 lasers mark a variety of materials.

Material Selection

| Material name | UV Laser Marker MD-U Series |

Green Laser Marker MD-T Series |

Hybrid Laser Marker MD-X Series |

Fiber Laser Marker MD-F Series |

CO2 Laser Marker ML-Z Series |

|

|---|---|---|---|---|---|---|

| Resin | EP (epoxy resin) | very good | very good | very good | good | good |

| ABS (ABS resin) | very good | very good | very good | good | possible | |

| PBT | very good | very good | very good | good | possible | |

| PA | very good | very good | good | possible | good | |

| PC (polycarbonate) | very good | good | good | good | good | |

| PP (polypropylene) | very good | very good | good | possible | good | |

| PE (polyethylene) | very good | very good | good | possible | good | |

| PET | very good | not possible | not possible | not possible | very good | |

| PPS | very good | very good | good | possible | good | |

| PS (polystyrene) | very good | very good | good | possible | good | |

| PI (polyimide) | very good | very good | possible | possible | possible | |

| PVC (polyvinyl chloride) | very good | very good | good | good | very good | |

| Glass epoxy | very good | very good | good | good | good | |

| Metal | SUS (stainless steel) | good | good | very good | very good | not possible |

| Fe (iron) | good | good | very good | very good | not possible | |

| Al (aluminum) | good | good | very good | very good | not possible | |

| Ni (nickel) | very good | very good | good | good | not possible | |

| Cu (copper) | very good | very good | good | possible | not possible | |

| Au (gold) | very good | very good | good | possible | not possible | |

| Other | Ceramic | very good | very good | good | good | good |

| Si (silicon) | very good | very good | good | possible | possible | |

| Paper | good | good | good | good | very good | |

| Rubber | very good | very good | very good | very good | very good | |

| Glass | good | not possible | not possible | not possible | very good | |

| Wood | possible | possible | possible | possible | very good |

Scroll

*The evaluations for the symbols given in the table vary depending on the state and additives of the target as well as on the set conditions. Use this information as typical examples

Fiber Laser Feature: High Power Laser Engraving

A fiber laser engraves by heating the material until a point of vaporization, leaving an engraved marking behind. Fiber lasers have a much higher output power than conventional laser markers. As a result, they're able to perform most applications at a much faster pace. Choose a fiber laser marker when you need a fast mark or a deep engrave on metal.

How to Choose the Best Fiber Laser Engraving Machine

Choosing your fiber laser engraving machine depends on your production size, intricacy of designs, and type of engraving. Let’s take a deeper look at each.

Production Size

If you have a small production size and parts, you may choose a table-top fiber laser engraver or a desktop laser. These laser systems are not integrated into a process line and require manual changeover, often referred to as "offline" marking.

Alternatively, if you’re involved in mass production or engraving large parts, choose an automated fiber laser engraving machine. Automated laser engravers are integrated into the process line and perform repetitive tasks, often referred to as "inline" marking.

Intricacy of Designs

The type of designs you need your laser to engrave will determine the type of software and beam you require. For those creating custom or elaborate designs, you will need a fiber laser engraving machine with high-quality software that can imitate these designs. Additionally, if you plan to mark on a curved surface or surface that has any change in depth, you will benefit from a laser beam that engraves on 3-axes.

Type of Engraving

If you’re in the market for a laser marker that can engrave deeply or engrave on hard materials, you’ll need a low peak and long pulse laser. On the other hand, if you need higher quality and precision or engraving on sensitive materials, you should opt for a high peak and short pulse.

We’re here to provide you with more details.

Reach out today!

Product Introduction

3-Axis Fiber Laser Marker MD-F Series

50 W/30 W High Power

The MD-F fiber laser’s high power output enables deep engraving and high-speed processing.

Scanner Control for Each Application

The MD-F fiber laser markers optimize their scanner movement, providing better marks in less time for nearly every application.

Environmentally Resistant, Fan-Less Head

The MD-F fiber laser engravers are sealed off from the environment (IP64 rated) and boast a fan-less marking head, making them robust enough to perform in dirty, dusty, wet and oily environments.

3-Axis Control

The 3-axis control is a function of the MD-F fiber laser machine which allows for variable changing of the laser's focal point throughout the marking field. Most fiber laser machines have fixed focal points, which leads to distorted processing because the beam cannot mark across the target uniformly. However, the adjustable fiber laser beam spot can effortlessly mark throughout the marking field with no distortion. It even marks 3-dimensional shapes such as cylinders, slopes, spheres, etc., without the need for external motion of parts.

Automatic Position and Focus Correction 3-Axis Hybrid Laser Marker MD-X Series

Built-in Vision

The MD-X Series contains a camera inside the laser marking head which can automatically identify a target’s shape. The laser marker can then adjust for X, Y, and theta offsets to ensure the marking position is always correct. The marking system is even able to distinguish between parts and mark each part accordingly.

Autofocus Anywhere

The MD-X laser marker comes standard-equipped with a built-in distance sensor that enables automatic focal corrections. Eliminate manual height adjustments due to part variations in a few simple steps.

Data-Driven Analytics

The MD-X uses predictive maintenance to eliminate problems before they occur. In the unlikely event of a marking defect, the laser marker features a wide range of diagnostic tools to identify the root cause and deploy countermeasures.

Get detailed information on our products by downloading our catalog.

View Catalog

Differences Between CO2 Laser and Fiber Laser

CO2 lasers and fiber lasers both use infrared range light. However, they process differently. Fiber lasers use a wavelength of 1090 nm, while CO2 lasers use 10x that—a 10600 nm wavelength. Because of the drastic difference in wavelengths, fiber and CO2 lasers are generally purposed for very different applications.

The high heat of CO2 lasers makes them optimal for processing transparent targets that don’t absorb fiber laser light. Likewise, fiber lasers process metals that do not absorb CO2 laser light.

However, these lasers are both excellent for laser cutting. Both a CO2 and fiber laser machine will excel at cutting because of their high output power.

Differences Between UV Laser and Fiber Laser

UV lasers and fiber lasers use different methods for processing; therefore, these lasers are not interchangeable. While the fiber laser uses an infrared laser with a wavelength of 1090 nm for heating materials, UV lasers use a 355 nm UV laser. Additionally, instead of traveling through a fiber, UV lasers travel through two crystals to reach the final beam point.

Because these lasers use different methods, they process completely different materials. Since the 355 nm wavelength of a UV laser is so readily absorbed, it processes material through photolytic degradation or “cold marking.” This allows for high-contrast marking with little to no thermal impact on the product being marked. Because of the lack of heat stress, UV lasers are commonly used on sensitive materials like paper, plastic, resin, and cardboard. They are commonly used for marketing metals in specific industries where surface finish, depth, and material properties of products cannot be compromised.

Fiber Laser Machine Safety

Fiber lasers are classified as Class 4/Class IV lasers by the FDA and IEC. Class 4 means that skin exposure and indirect/direct viewing of a fiber laser are potentially dangerous.

KEYENCE’s Fiber Laser Machine Integrated Safety Measures

Many fiber lasers come with integrated safety measures for preventing harm. KEYENCE’s fiber laser includes a key control, radiation emission warning, a laser shutter, an emergency stop input terminal, a manual reset option , along with redundant safety through a contactor that is ISO 13849-1 compliant.

Key Control

KEYENCE’s fiber laser turns on and off with the turn of a key.

Radiation Emission Warning

A laser radiation emission indicator lights up when the key-operated switch turns the machine on.

Laser Shutter

When the fiber laser is on, a shutter encloses the beam to prevent laser beam emission.

Emergency Stop

The fiber laser includes two input terminals. If one is opened, the laser automatically stops.

Manual Reset

If an error occurs in the laser, the laser must be manually turned back on. The manual control prevents the laser from turning on when an error is not resolved.

ISO 13849-1 Compliance

KEYENCE laser markers can be made ISO 13849-1 compliant and achieve PLe, the highest performance level rating.

Discover more about this product.

Click here to book your demo.

Organizational Safety Measures for Using Fiber Laser Machines

Fiber Laser Machine Location

Always put a warning sign at the entrance of the laser area. The sign will alert all traffic to adhere to laser safety standards. Additionally, ensure there is a local ventilation system if gas is emitted from your laser engraver.

Fiber Laser Machine Protective Clothing and Goggles

Always wear protective clothing and eye protection goggles that cover as much skin as possible when operating a fiber laser. Make sure the protective goggles are specifically made for fiber lasers.

Fiber Laser Machine Safety Management System

Before setting up your laser, appoint a laser safety officer. Your laser safety officer should have prior knowledge and experience with a fiber laser marking machine and related safety.

A Laser Safety Officer is responsible for the following:

- Establishing fiber laser emission prevention measures.

- Setting up the fiber laser location.

- Managing key, protective equipment, and training.

Get Started with KEYENCE Fiber Laser Technology

Starting with the fiber laser for engraving from KEYENCE gives you access to technology made for the various demands of contemporary manufacturing. Our fiber laser marking solutions offer the accuracy and dependability you require, whether your aim is to improve branding with logos, meet industry regulations, or improve product traceability.

With easy-to-use software, KEYENCE helps companies incorporate fiber laser technology into their current production lines. Contact us today to find out how state-of-the-art fiber laser equipment can improve the accuracy and efficiency of your manufacturing process.

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

Related Downloads

KEYENCE's MD-F Series offers unmatched functionality in a compact design.

This quick guide introduces the basics of metal marking. Learn why different wavelengths matter and discover the various ways laser light interacts with metal parts.