Industrial Laser Marking Systems / Laser Markers

4 Common Problems & Solutions of Laser Marking Machines

-

Tags:

- Laser Marking , Laser Etching , Laser Labeling

Laser marking machines are gaining popularity for their high-contrast and permanent marks that do not add force or damage to materials. But what do you do when your laser marking machine is not working as promised or if you’re running into laser marking software challenges?

Although you may quickly turn to laser marking machine maintenance, the solution may be even simpler. If you’re having difficulty with your laser marking machine, and laser marking troubleshooting isn’t working, keep reading to learn about the four common problems and solutions of laser marking machines to enhance your equipment’s performance.

What is a Laser Marking Machine?

A laser marking machine is an automated tool that can etch, engrave, anneal, clean, and texture a target using a laser beam. Targets of laser marking machines span across industries and materials. A laser marking machine can mark glass, plastic, rubber, wood, paper, metal, and resin across almost every industry.

Laser marking machines are versatile machines that anyone can use. But with so many features, it’s easy to face problems with picking the correct output, type of laser, contrast, and program.

We’re here to provide you with more details.

Reach out today!

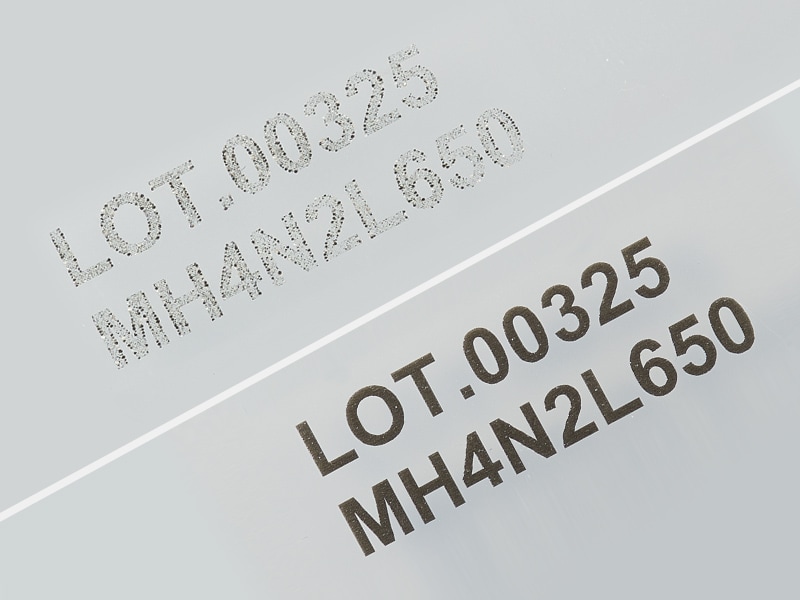

Problem 1 – Inconsistent Marking Quality

Poor marking quality ranks among the most frequent laser marking machine challenges operators face. Uneven depth, faded characters, or incomplete marks can derail production schedules and waste materials.

Potential Causes: Power Settings, Focus, or Speed

Results are inconsistent for a number of reasons. Marks made with improper power levels are either too deep or too faint. Inaccurate impressions are often caused by poor focus alignment. Unfinished marking cycles are caused by speed settings that are out of sync with material attributes. The quality of beams is also diminished by environmental factors such as dust on optical components and temperature variations.

Solution: Optimize Parameters Based on Material

Start by testing small sample areas with different parameter combinations. Each material responds differently to laser energy. Document successful configurations for future reference. Clean optical components weekly and check focus alignment monthly.

Problem 2 – Difficulty Marking Plastics

Challenges of laser marking on plastics stem from their chemical composition and thermal properties.

Why Plastics Are a Challenge

Most plastics have low melting points and poor heat conductivity. Some release toxic fumes when heated, requiring proper ventilation. Others contain additives that interfere with laser absorption. White plastics may not absorb enough energy for visible marks, while dark plastics can overheat and create burn marks.

Recommended Settings and Laser Types

The majority of plastic applications are better served by UV lasers. With fiber lasers, lower frequencies or higher peak power often deliver better results. Intentionally defocusing the laser (easier on some lasers than others) can increase the likelihood of marking without burning. Certain types of plastic can be used with CO2 lasers, although these marks will most likely be melted into the part. Depending on the thickness of the plastic, experiment with different marking rates.

Problem 3 – Machine Error Codes

Laser marking troubleshooting becomes straightforward once you understand common error messages.

How to Clear and Prevent Future Errors

Power cycling resolves many temporary errors. Turn off the machine for 30 seconds before restarting. Check cable connections if communication errors persist. Regular software updates prevent many error conditions. Laser marking software challenges often disappear after updating firmware.

Problem 4 – Misalignment or Blurry Marks

Misaligned marks waste materials and require rework. Blurry impressions indicate optical problems.

When to Check Fixturing or Optics

Most alignment issues stem from the presentation of the part, when marks land in the wrong location this is typically a fixturing or part presentation issue. If marks are blurry or a combination of clear and blurry, this is likely due to contaminates blocking the laser light. Check for debris, dirt, or oil on the lens of the laser.

Discover more about this product.

Click here to book your demo.

Preventive Maintenance Tips

Regular maintenance prevents most common problems. Clean optical components with appropriate solvents and lint-free cloths. Replace consumable parts according to manufacturer schedules.

When to Schedule Professional Maintenance

Complex repairs require factory-trained technicians. Schedule professional service when error codes persist after basic laser marking troubleshooting.

How to Get the Best Use Out of Your Laser Marking Machine

The most important tip to ensure the best use of your laser marking machine is to research your laser marking machine before marking. Although laser marking machines are versatile tools that easily tackle a range of materials, industries, sizes, and types of processing, it is essential to understand how your target interacts with the laser beam’s heat source, frequency, power, and output.

Define the materials you’re working with and your design goals so you can align your laser marking machine best with your needs. Before sending your machine to receive laser marking maintenance, explore the settings, outputs, and powers to recognize the range it produces. It may not be that your laser marking machine is broken. It may just be used incorrectly.

Want to Learn More About Laser Marking Machines?

At KEYENCE, we know laser marking machines have complexities, so we’ve committed to educating our customers for the best laser marking experience.

Using a laser marking machine can put you ahead in your industry by saving you money and time if you use it correctly. Additionally, these machines are environmentally friendly and require no consumables, so mastering the art of using a laser marking machine can benefit the world beyond your business.

Check out our laser marking machines’ resource page to learn more about each type of laser, what they do, and how to achieve optimal use. Prefer a more hands-on approach? Contact us for a demo; our knowledgeable team will guide you to the best laser marking machine for your goals!

Contact us to learn more about how our advanced technology can help take your business to the next level.

Contact Us

FAQs

What do I do if my laser marking machine suddenly shuts down mid-operation?

Check power connections and error displays first. Most sudden shutdowns result from thermal protection issues. Allow cooling time before restarting.

Can laser marking damage the material if not set correctly?

Yes, incorrect settings can burn, melt, or discolor materials. Always test parameters on sample pieces first.

Is it safe to attempt laser marker repairs without factory support?

Basic maintenance is safe. However, lasers are intricate and accurate pieces of machinery, performing repairs on manufacturing floors can lead to debris impacting the mark accuracy or quality. It's suggested that complex electrical or optical repairs require professional service.

What causes material damage when using a laser marking machine?

Excessive power, wrong speed settings, or poor focus alignment typically cause damage.

How do I know if my laser marking machine needs repair?

Persistent error codes, declining mark quality, or unusual noises indicate repair needs.

We’re here to provide you with more details.

Reach out today!